MP3 product shell pressing and assembling device

A technology for assembling devices and pressing devices, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven pressing, operator injury, and product inconsistency, and achieve high assembly efficiency and improved Safety and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to describe the technical solution of the above-mentioned invention in more detail, the following inventors list specific examples to illustrate the technical effects; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

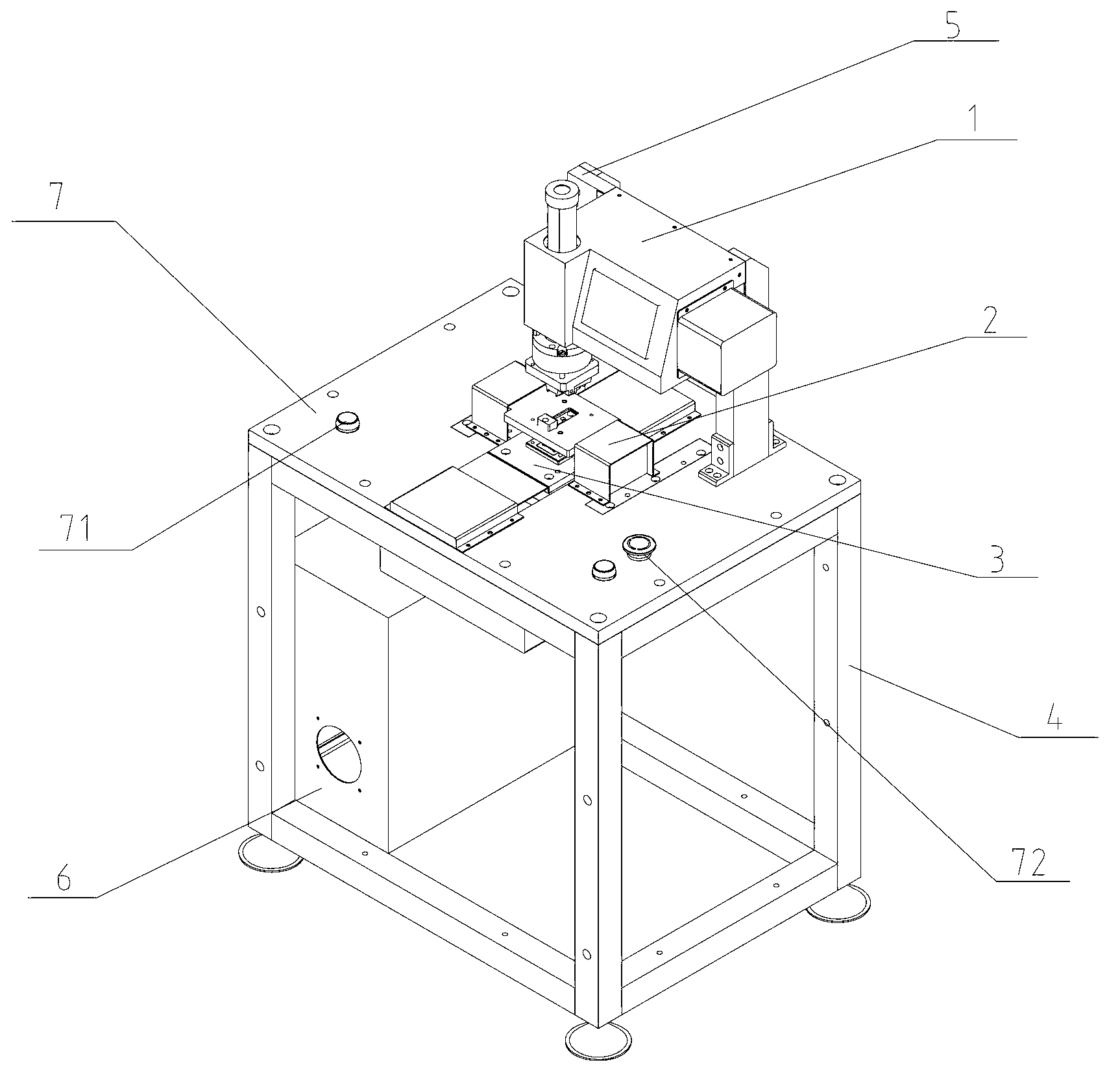

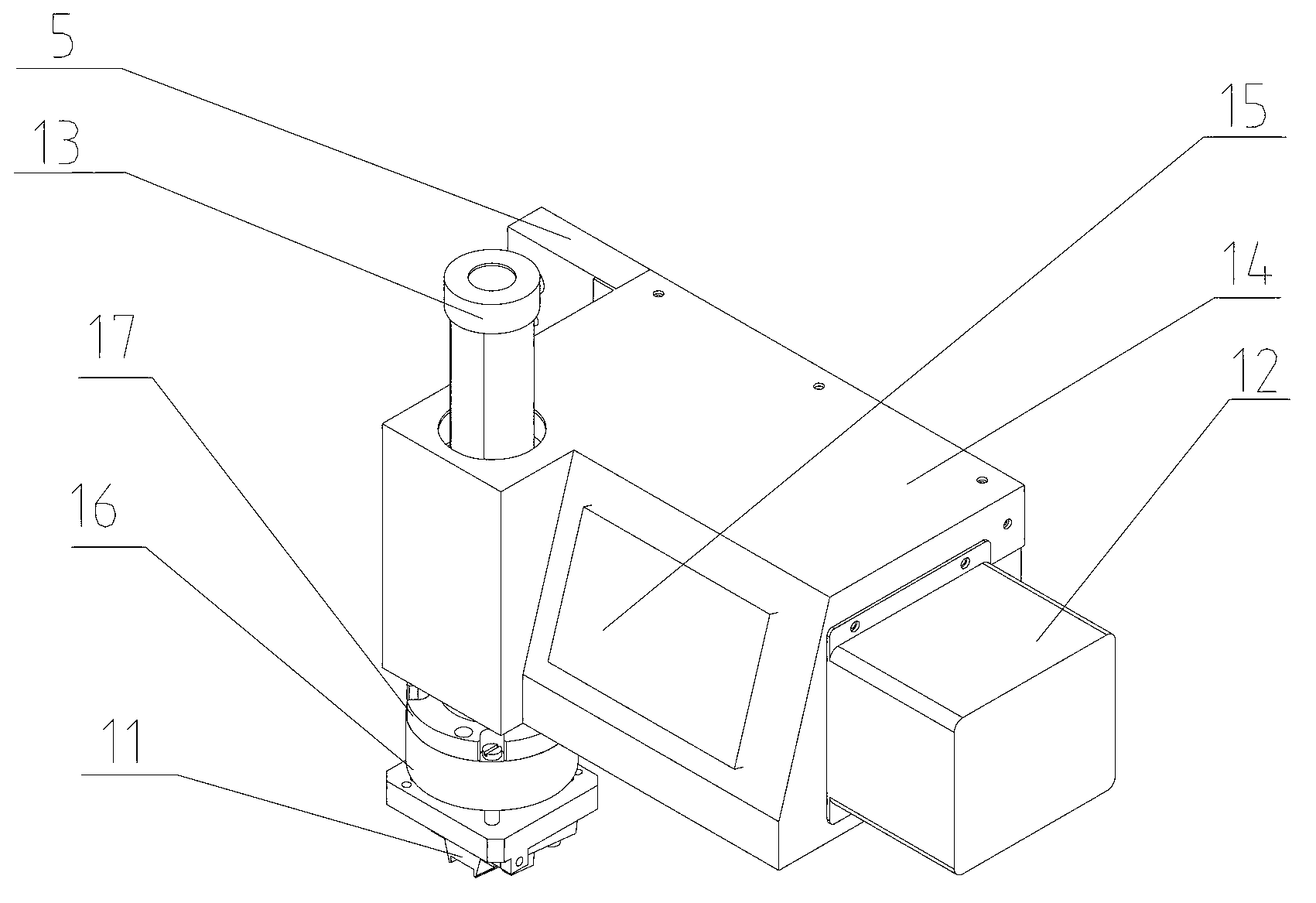

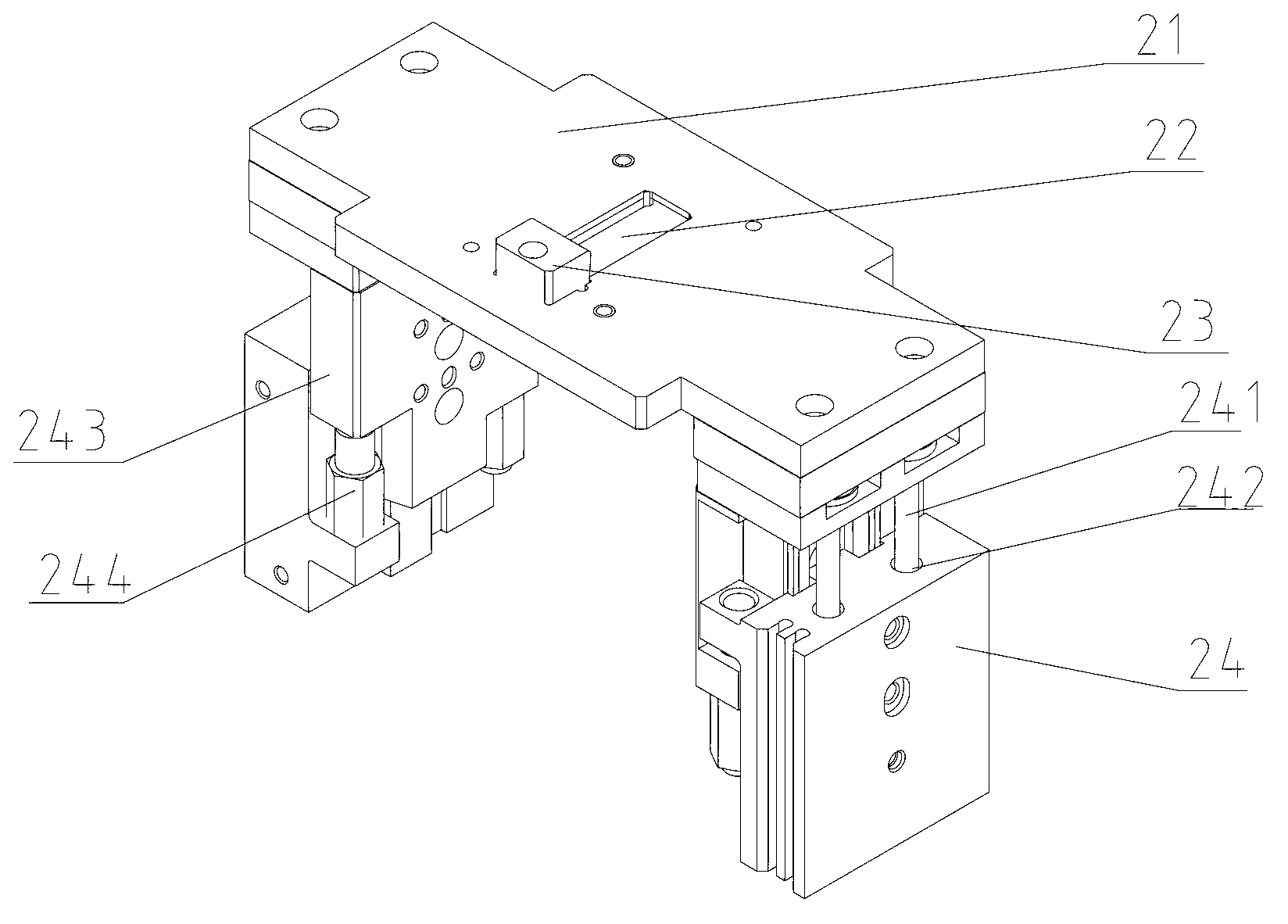

[0037] Example Figure 1~4 , the MP3 product shell lamination equipment includes a product input and output device and a lamination device 1 fixed on the frame 4, and a middle plate guide device 2 is arranged between the input and output device and the lamination device; the middle plate guide device It is fixed on the workbench 7, and the pressing device 1 is fixed on the workbench through the gantry brace 5; the start switch 71 and the emergency stop switch 72 are set on the workbench.

[0038] The product input and output device includes a base plate 31, which is fixedly arranged on the frame 4 of the MP3 product shell pressing equipment, and a slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com