Tank clamping and releasing mechanism

A release mechanism and tank technology, applied in the direction of feeding device, positioning device, application, etc., can solve the problems of complex clamping mechanism, cumbersome operation process, and inability to adapt to automatic operation requirements, so as to simplify clamping and releasing The effect of simple process and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

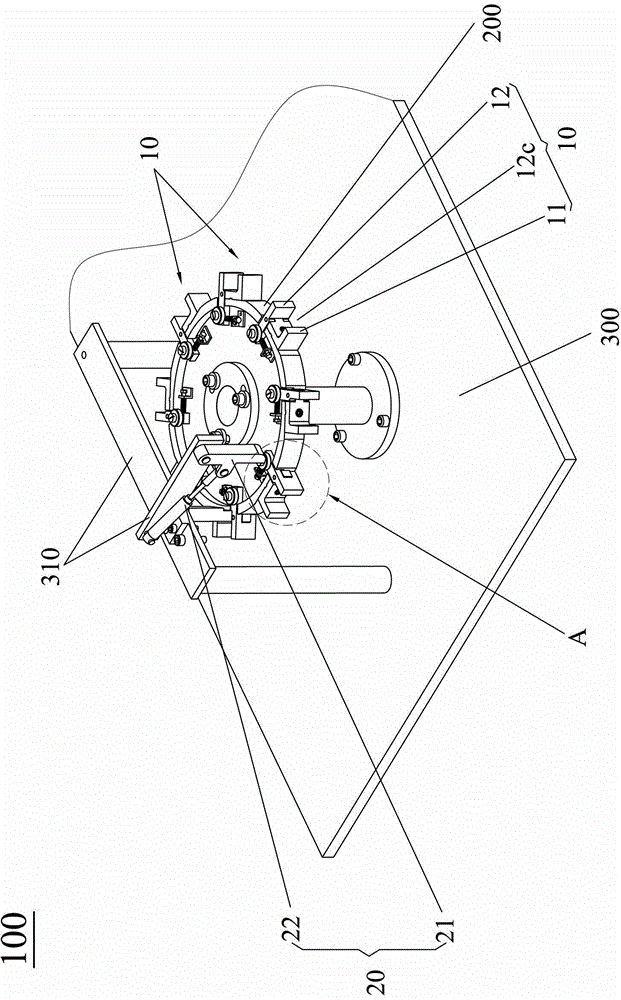

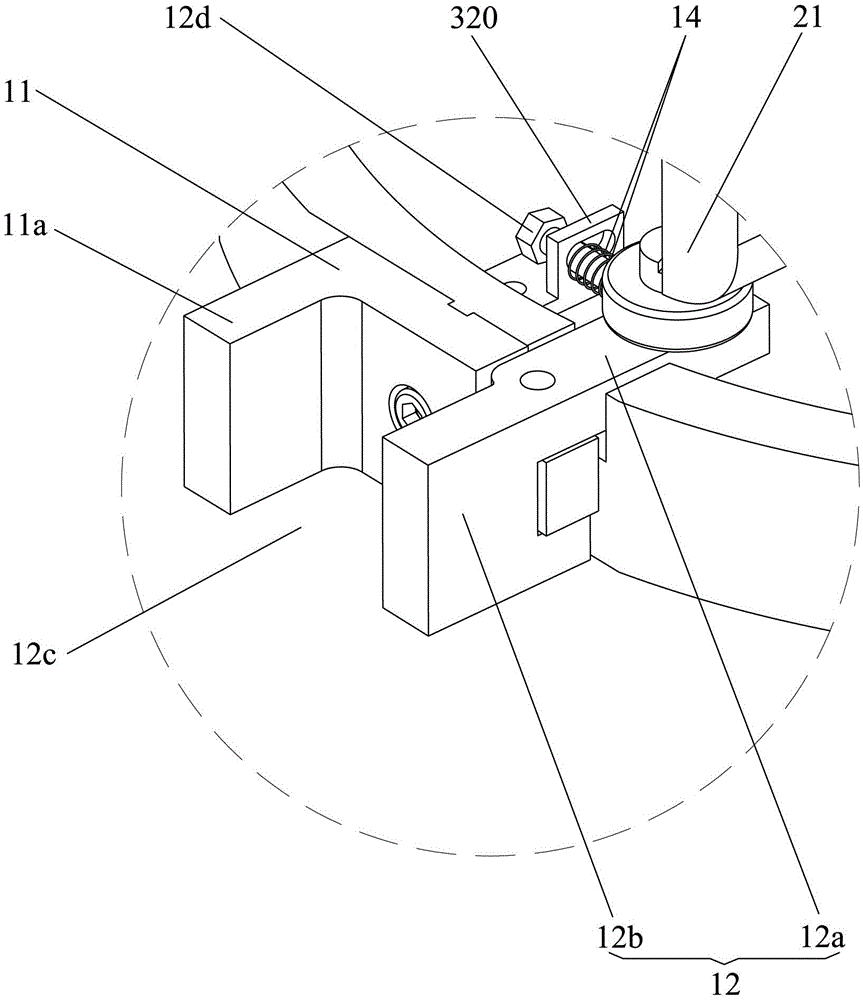

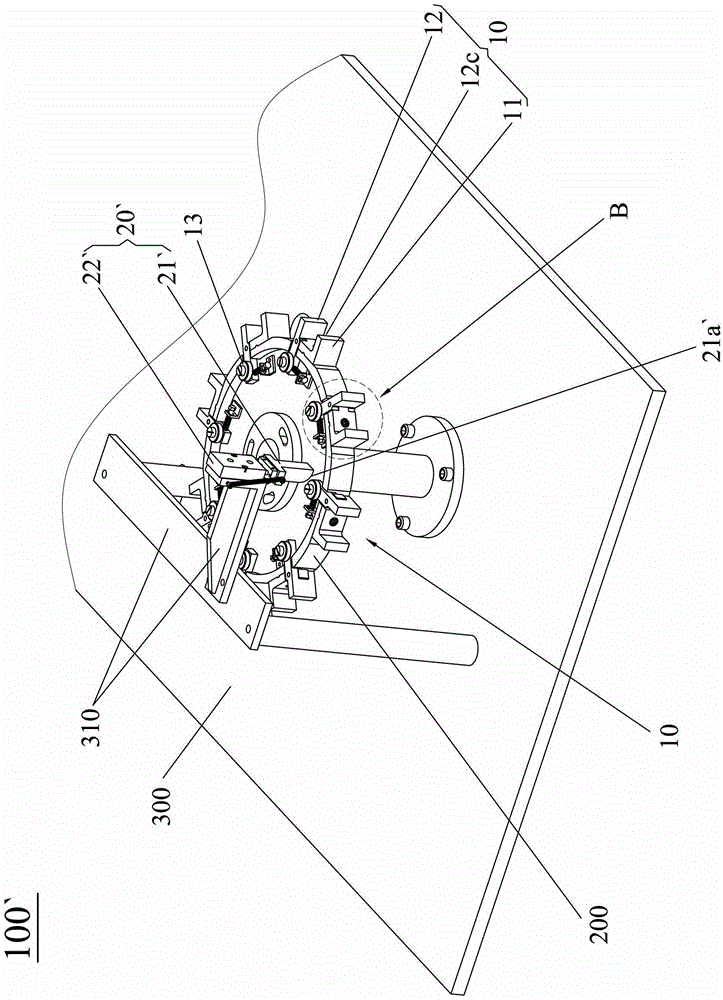

[0021] see figure 1 , figure 1 The first embodiment of the clamping and releasing mechanism of the tank body of the present invention is shown, combined with figure 2 with Figure 5 , the can body clamping release mechanism 100 of this embodiment is used to automatically clamp and release the can body 400 conveyed from the production line, wherein the can body clamping release mechanism 100 includes a release device 20 and several clamping devices 10 . The clamping device 10 is arranged on the external rotating table 200 along the circumferential direction so that the clamping device 10 has a circular layout on the rotating table 200, and the rotating table 200 is rotatably installed on the external mounting base 300 above so that the rotating table 200 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com