A staggered-level closing installation method for long-span steel structures

An installation method and steel structure technology, applied in building construction, processing of building materials, construction, etc., can solve problems such as inability to work, and achieve the effects of increasing stability, reducing bending moment, and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The invention discloses a large-span steel structure staggered closing installation method, which includes the following construction steps:

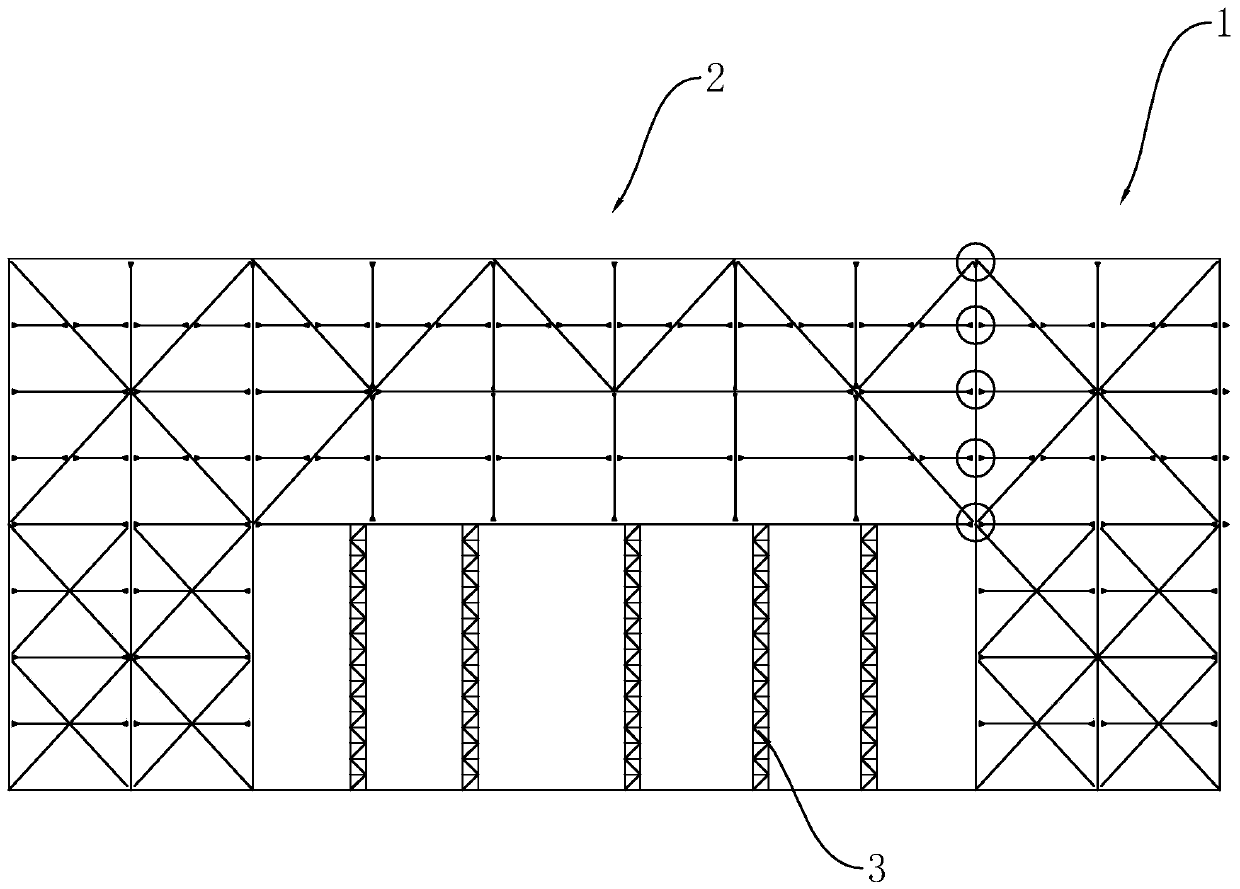

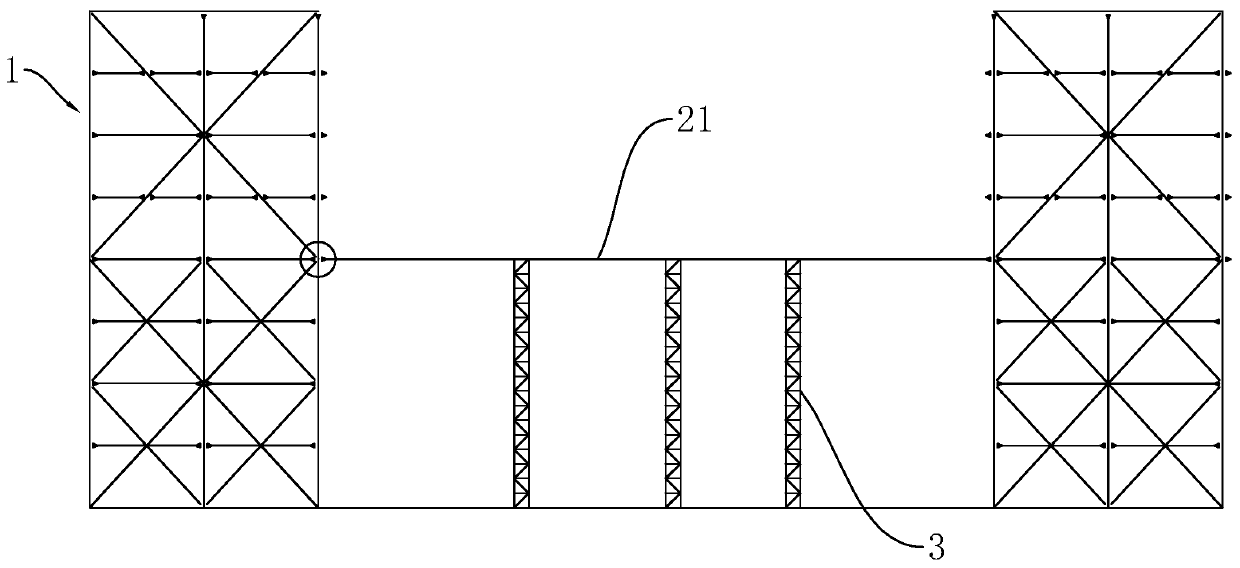

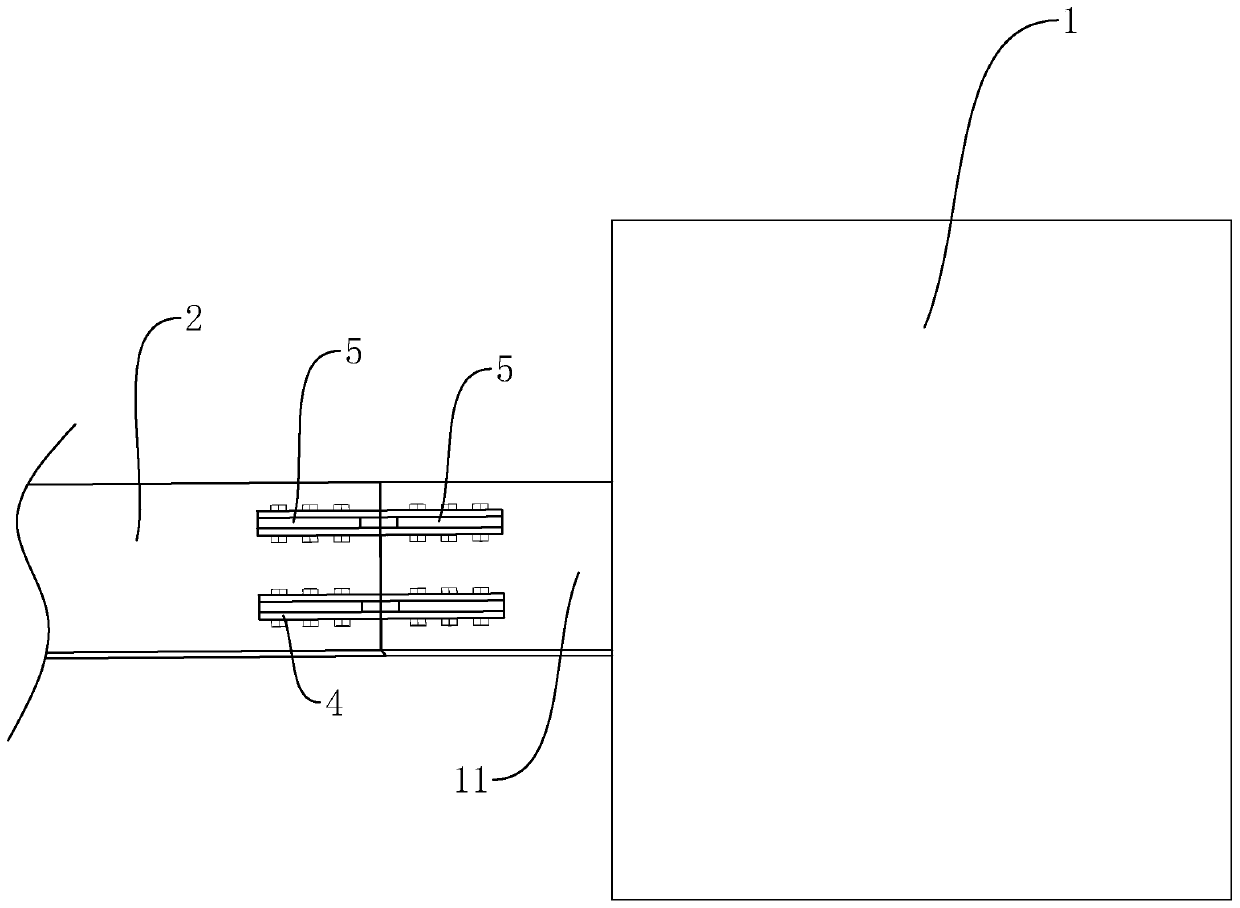

[0045] S1. Support frame installation: refer to figure 2 Firstly, the ground below the steel beam 2 is rolled and concrete is poured to harden, so as to enhance the compressive capacity of the ground, prevent the subsidence of the ground foundation, and improve the safety in the construction process and the accuracy of the installation of the steel beam 2 . Three rows of support frames 3 are installed on the ground for supporting the steel beams 2 .

[0046] S2. Installation of beams on the first floor: refer to figure 2, hoist the first floor beam 21 to the installation position and make the support frame 3 support the first floor beam 21, butt one end of the first floor beam 21 with the corbel 11 on one side of the core tube 1 and then weld and fix it, and the other end and the other The corbel 11 on one side core tube 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com