Dosing device and dosing method for liquids

一种液体、液体流动控制的技术,应用在液体装瓶、液体处理、液体材料等方向,能够解决不足以抑制泡沫等问题,达到减少飞溅和泡沫的产生的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

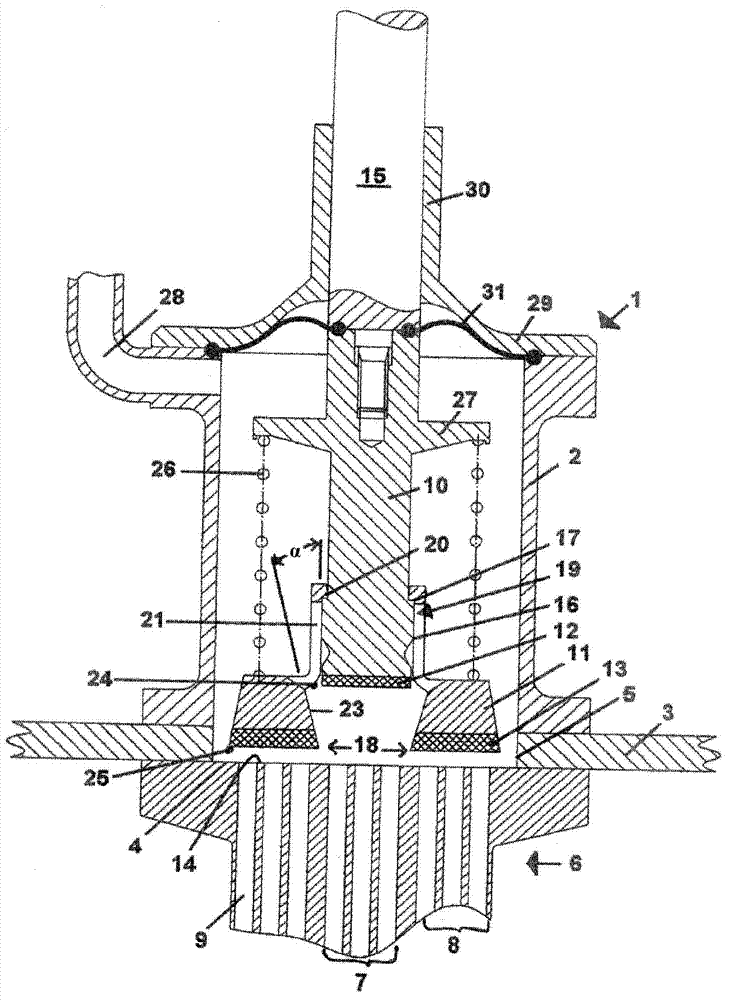

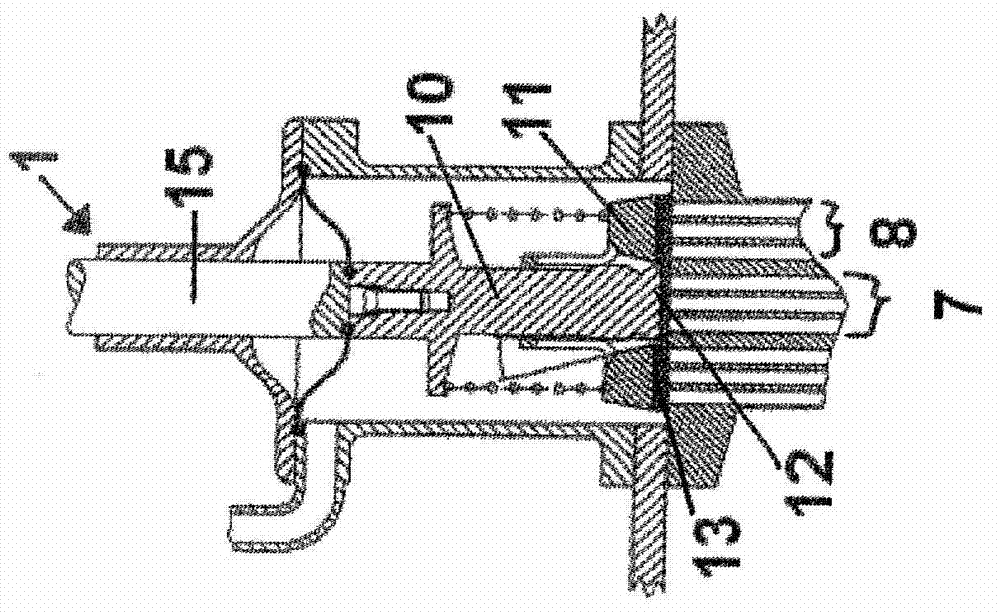

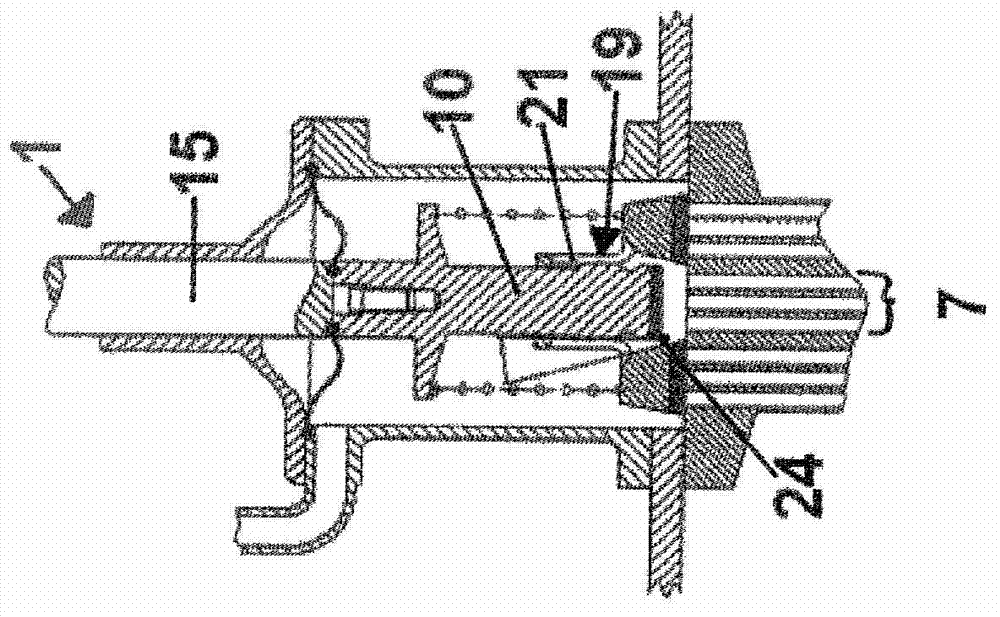

[0037] Firstly, the metering device 1 comprises a valve housing 2 which is arranged on the cover plate 3 of the filling chamber. In a filling chamber, not shown, containers, especially packagings made of composite material, are filled with a liquid, for example fruit juice. The outlet 4 of the metering device 1 is aligned with the passage 5 in the cover plate 3 corresponding to its outlet cross-section. Concentrically arranged below the cover plate 3 to the outlet 4 of the metering device 1 is a cylindrical outlet opening 6 known per se. The outflow opening 6 can of course also be fixed directly on the metering device 1 .

[0038] The outflow opening 6 is functionally divided into a central outflow opening 7 and an edge outflow opening 8 surrounding the central outflow opening. Both the central outlet opening 7 and the peripheral outlet opening 8 are formed by a plurality of cylindrical, preferably cylindrical, passages 9 distributed adjacent to one another in the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com