Apparatus for purifying exhaust air

A technology that discharges air and cleans it. It is applied to combined devices, using liquid separating agents, and separating particles. It can solve the problems of increased pressure loss of discharge air flow, high energy consumption, and loss of device efficiency, and achieves a reduction in liquid loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

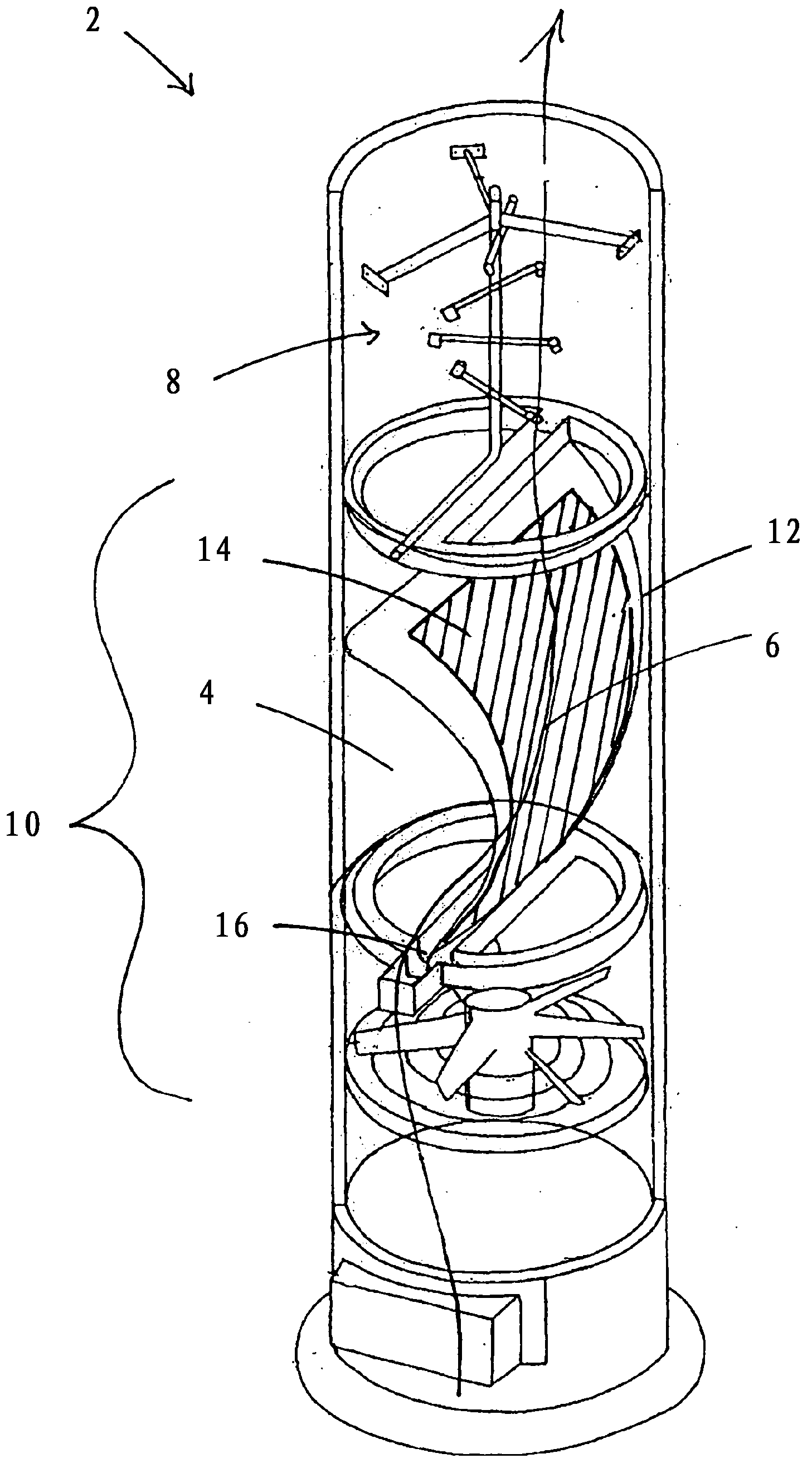

[0021] The device 2 has a flow channel 4 through which an exhaust air flow 6 flows in the flow direction. Located in the flow channel 4 is a liquid injection device 8 , by means of which liquid can be injected into the discharge air flow 6 . In the present exemplary embodiment, the flow channel 4 has a substantially vertical course, wherein the exhaust air flow 6 flows through the flow channel 4 from bottom to top. At a wind speed of the discharge air stream 6 in the device 2, which usually varies in the range of 5 m / s to 9 m / s, the droplets of the liquid sprayed by the liquid ejection device 8 are not forced to follow the flow direction of the discharge air stream 4 Instead, the droplets fall downwards against the direction of flow of the discharge air stream 4 under the force of gravity. The droplets thus reach the region of the particle separator 10 .

[0022] Unlike the present exemplary embodiment, the particle separator 10 can also be arranged downstream of the liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com