Loudspeaker testing device

A technology for testing devices and speakers, applied in the direction of electrical components, etc., can solve the problems that the sound quality of speakers cannot be guaranteed, reduce production efficiency, and consume

Active Publication Date: 2012-11-21

HUIZHOU JINSHAN ELECTRONICS

View PDF3 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The sound quality testing steps are separated from the production line, which not only reduces the production efficiency, but also consumes more manpower to participate in the handling of the speakers, which increases the production cost; the experience of the testers is used as the judgment standard for the sound quality of the speakers, resulting in the quality of the products. Unified control, the sound quality of the speaker cannot be guaranteed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

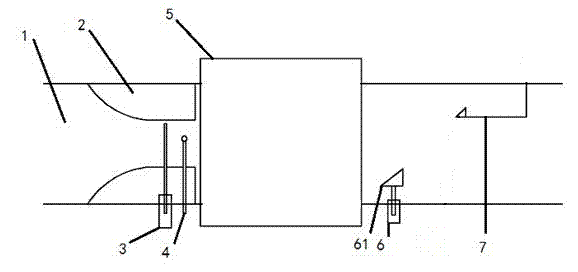

[0045] This embodiment discloses a horn testing device, which includes a stroke control mechanism for guiding and controlling the stroke of the horn to be tested from the upstream of the conveyor belt 1, and a testing mechanism arranged downstream of the stroke control mechanism and used for testing the horn to be tested.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a loudspeaker testing device which comprises a travel control mechanism, a testing mechanism, a screening mechanism and a control mechanism, wherein the travel control mechanism is used for guide and travel control of to-be-tested loudspeakers coming from the upstream of a conveying belt; the testing mechanism is arranged on the downstream of the travel control mechanism and used for testing the to-be-tested loudspeakers; the screening mechanism is arranged on the downstream of the testing mechanism and used for screening qualified loudspeakers and defective loudspeakers; and the control mechanism is used for controlling the travel control mechanism, the testing mechanism and the screening mechanism. The loudspeaker testing device is high in production efficiency and capable of automatically performing online testing for the loudspeakers.

Description

technical field [0001] The invention relates to the technical field of horn testing equipment, in particular to a horn testing device. Background technique [0002] The speaker sound quality testing steps in the known speaker production process are all completed manually: the finished speaker products transmitted from the upstream of the production line are manually transferred to a quiet listening room, and the sound quality is tested based on the experience of the testers. The sound quality testing steps are separated from the production line, which not only reduces the production efficiency, but also consumes more manpower to participate in the handling of the speakers, which increases the production cost; the experience of the testers is used as the judgment standard for the sound quality of the speakers, resulting in the quality of the products. Unified control, the sound quality of the speaker cannot be guaranteed. Contents of the invention [0003] The object of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H04R29/00

Inventor 唐华吴洋梁志昌

Owner HUIZHOU JINSHAN ELECTRONICS

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com