Quick spline type connection structure of battery pack

A technology for connecting structures and battery packs, applied to battery pack parts, structural parts, circuits, etc., can solve problems such as shortening battery life, destroying the internal structure of the battery, and harming the battery and personnel, so as to ensure battery life and facilitate use , is conducive to the effect of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

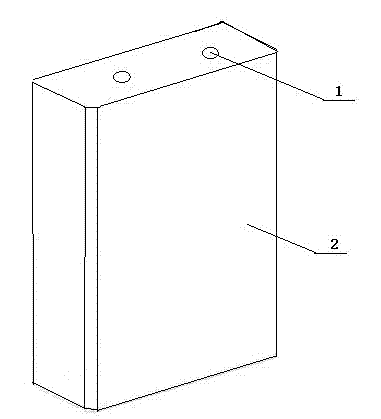

[0016] Embodiment: the quick spline connection structure of battery pack, as figure 1 with 2 As shown, it mainly includes a battery 2 and a connection plate 3. The main improvement is that the battery 2 is provided with a groove 1 connected to the positive and negative electrodes inside the battery 2 respectively, and a post 4 is fixed on the connection plate 3, and the post 4 is an external The surface has a cylindrical shape with circular arc protrusions; the internal structure of the groove 1 matches the column pile 4; one side of the connecting plate 3 has a soft rubber plate 5.

[0017]

[0018] In the embodiment, there are two positive and negative grooves 1 on the upper surface of the battery 1, the depth of the groove 1 is 20mm, and the internal structure is similar to the form of a spline groove; The connecting plates 3 are fixed together, and the outer surface of the column pile 4 has a circular-arc convex cylindrical structure, which matches the internal structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com