Machine tool adopting hybrid programming automatic measurement and manual measurement as well as on-line measurement method of machine tool

A technology of automatic measurement and machine tools, applied in the direction of program control, computer control, instruments, etc., to achieve the effect of expanding process capabilities, expanding the scope of application of workpieces, and simplifying installation and adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

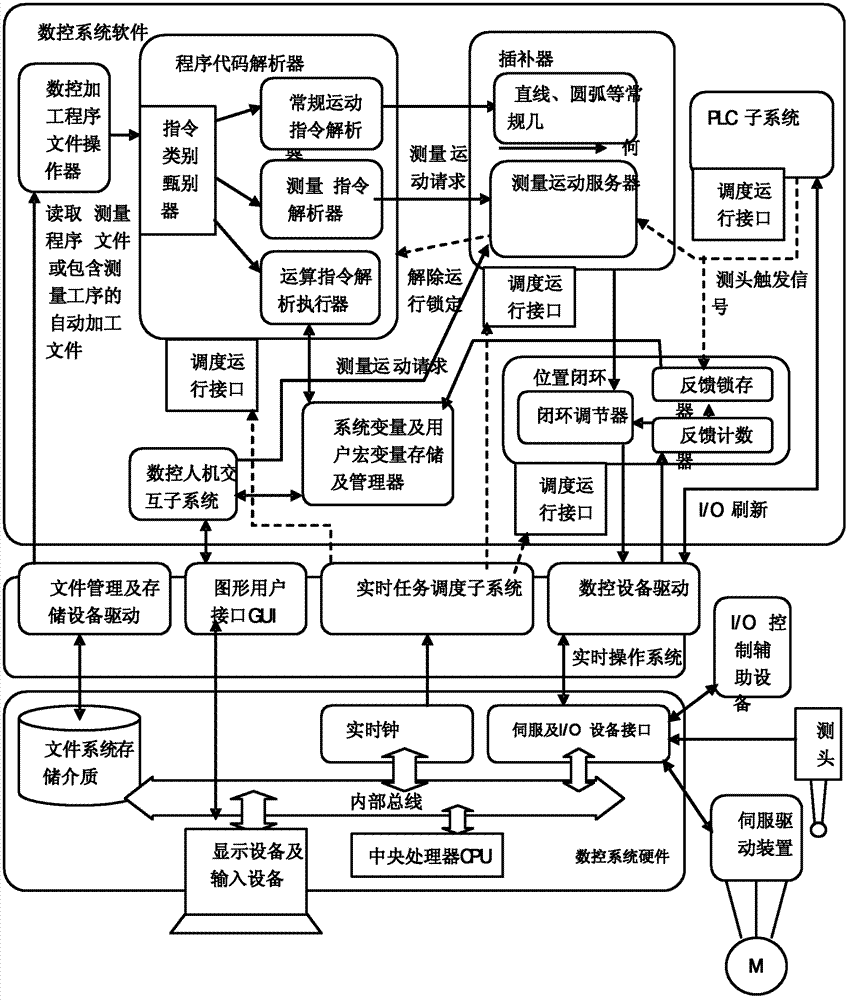

[0048] The control method proposed by the present invention has multiple implementation modes according to different operating systems and development tools selected by the numerical control system. image 3 One implementation of the invention is shown. The system consists of three parts: CNC system hardware, real-time operating system, and CNC system software.

[0049] Numerical control system hardware can be composed of a variety of computer systems, such as X86PC architecture, ARM processor architecture, DSP processor architecture, single-chip microcomputer architecture, and multi-CPU architecture composed of multiple above-mentioned processors. The central processing unit CPU is connected to other devices through the internal computer bus, including the real-time clock, servo and I / O device interfaces, storage media, display devices and input devices necessary for the numerical control system. The hardware system adopting the X86PC framework can use the internal 8253 or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com