Image heating apparatus

一种加热装置、图像的技术,应用在滚筒加热装置、电热装置、欧姆电阻加热等方向,能够解决闪烁噪声和温度起伏导通期和控制循环困难等问题,达到抑制温度起伏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

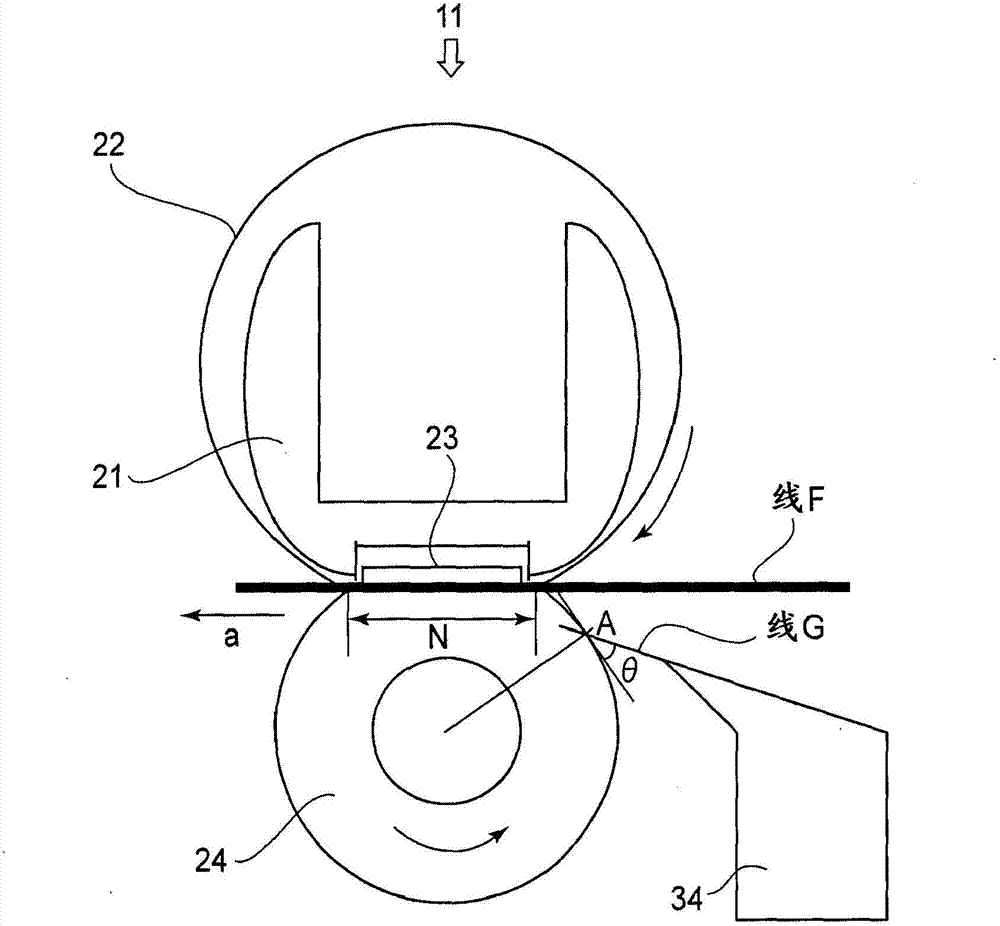

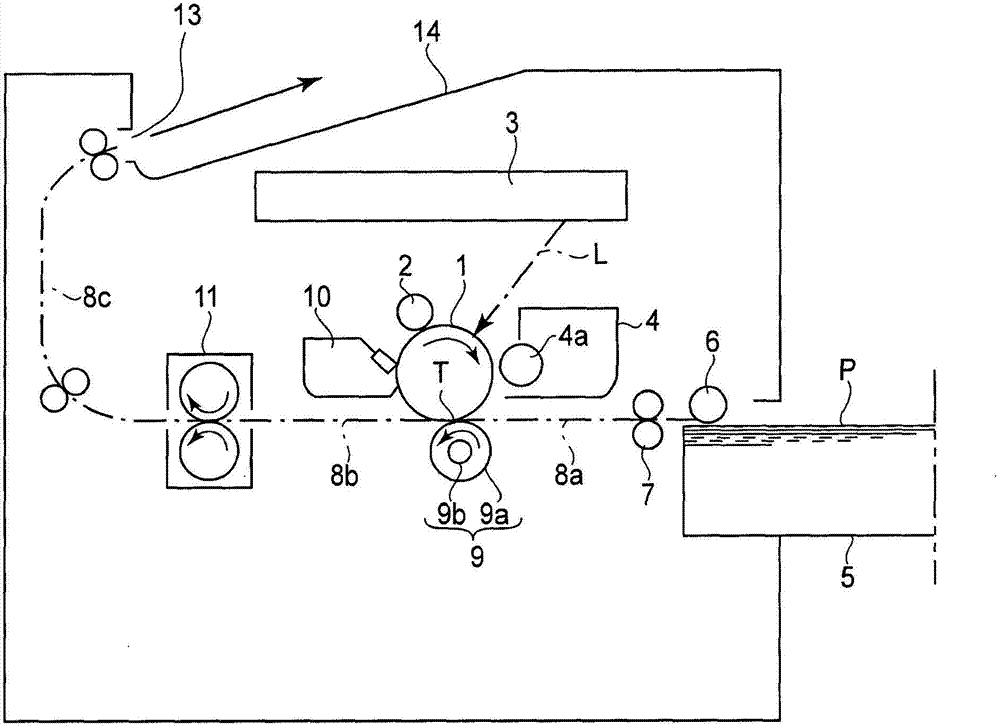

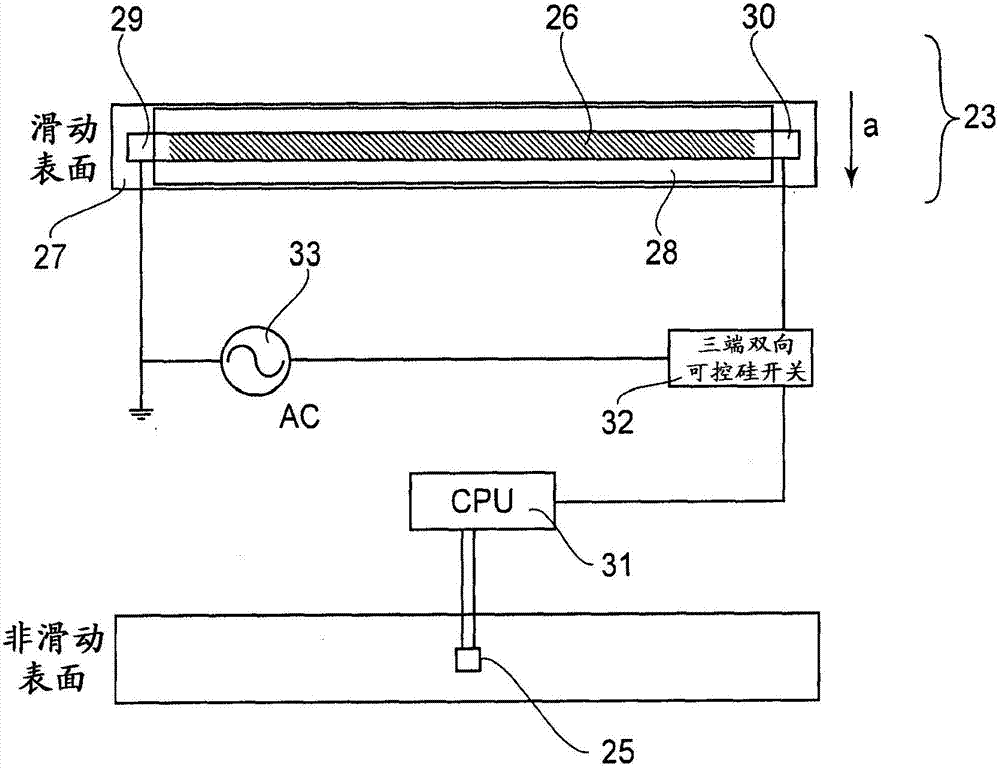

[0020] Hereinafter, Embodiment 1 of the present invention will be described with reference to the drawings.

[0021] figure 2 is a schematic illustration of the imaging device according to the present embodiment. The image forming apparatus in this embodiment is an electrophotographic type laser beam printer. In the present embodiment, description will be made taking as an example a configuration in which the processing speed is about 200 m / s, the FPOT is about 6 seconds, and (when A4 size recording material is used) the throughput is about 33 ppm.

[0022] An electrophotographic photosensitive (member) drum 1 as an image bearing member is rotatably driven in a clockwise direction indicated by an arrow at a predetermined peripheral speed (process speed).

[0023] The contact charging roller 2 serving as charging means uniformly charges the surface of the photosensitive drum 1 to a predetermined polarity and a predetermined potential (main charging).

[0024] A laser beam s...

Embodiment 2

[0088] In this embodiment, basically the same configuration as in Embodiment 1 is employed. The differences are mainly described below.

[0089] There are various voltage values for commercial power supplies depending on the country and region. For example, in the United Kingdom in Europe, the voltage value is 230V / 240V, in Germany, France, etc., it is 127V / 230V, in Asia, China, Korea, etc., it is 110V / 220V, in North America, the United States is 120V, and in Canada, it is 120V / 240V. Therefore, in some cases, imaging devices are narrowed down to imaging devices using an allowable voltage of 100V to 127V (machines supporting 100V) for the reason of obtaining commonality of imaging devices supplied to various countries to achieve cost reduction Two imaging devices consisting of an imaging device that uses an allowable voltage of 200 to 240V (machines that support 200V). In both the 100V-supporting machine and the 200V-supporting machine, the resistance value of the heater ...

Embodiment 3

[0111] This embodiment differs from Embodiment 1 in the following points.

[0112] In Embodiment 1, the image number control in which the conduction period of the heater 23 is controlled by using one half-wave of the commercial power supply as the minimum unit is employed, and on the other hand in the present embodiment, the image number control is employed in the same manner as the commercial power supply in which the The phase angle in one half-wave of the power supply is controlled by a combination of phase controls of the type controlled.

[0113] Combined control of the image number control and phase control will be described later.

[0114] As described above, the image number control is such that either 100% energization or no energization (0% energization) is carried out with respect to one half-wave in a predetermined control cycle. On the other hand, the phase control makes it possible to control the conduction period in a predetermined control cycle at multiple lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com