Automatic adjusting device of screw pair of single-screw pump

A screw and screw technology, applied in the field of automatic adjustment devices, can solve the problems of increased return flow, increased pressure drop, etc., and achieve the effects of reducing leakage, improving volumetric efficiency, and increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

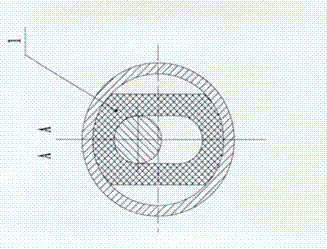

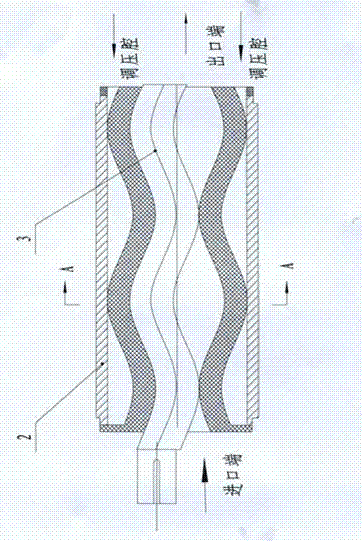

[0017] The screw pair includes a stator 1, a stator hoop 2 and a screw 3. The stator 1 is made of rubber; the stator hoop 2 is made of seamless steel pipe; the screw 3 is made of 45 steel. Stator 1 is a double-ended helical stator with equal wall thickness; its wall thickness is 5 mm. The stator 1 is fixed in the stator hoop 2 .

[0018] All the other technical features are the same as the technical solution.

Embodiment 2

[0020] The screw pair includes a stator 1, a stator hoop 2 and a screw 3. The stator 1 is made of rubber; the stator hoop 2 is made of seamless steel pipe; the screw 3 is made of 2Cr3. Stator 1 is a three-headed helical stator with equal wall thickness; its wall thickness is 10 mm. The stator 1 is fixed in the stator hoop 2 .

[0021] All the other technical features are the same as the technical solution.

Embodiment 3

[0023] The screw pair includes a stator 1, a stator hoop 2 and a screw 3. The stator 1 is made of rubber; the stator hoop 2 is made of seamless steel pipe; the screw 3 is made of 304 stainless steel. Stator 1 is a three-headed helical stator with equal wall thickness; its wall thickness is 20mm. The stator 1 is fixed in the stator hoop 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com