Slope masonry machine with modes of discharging, vibrating and sliding

A model and masonry technology, applied in the direction of architecture and infrastructure engineering, etc., can solve problems such as heavy follow-up workload, affecting the quality of slope masonry, and not easy to calender

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

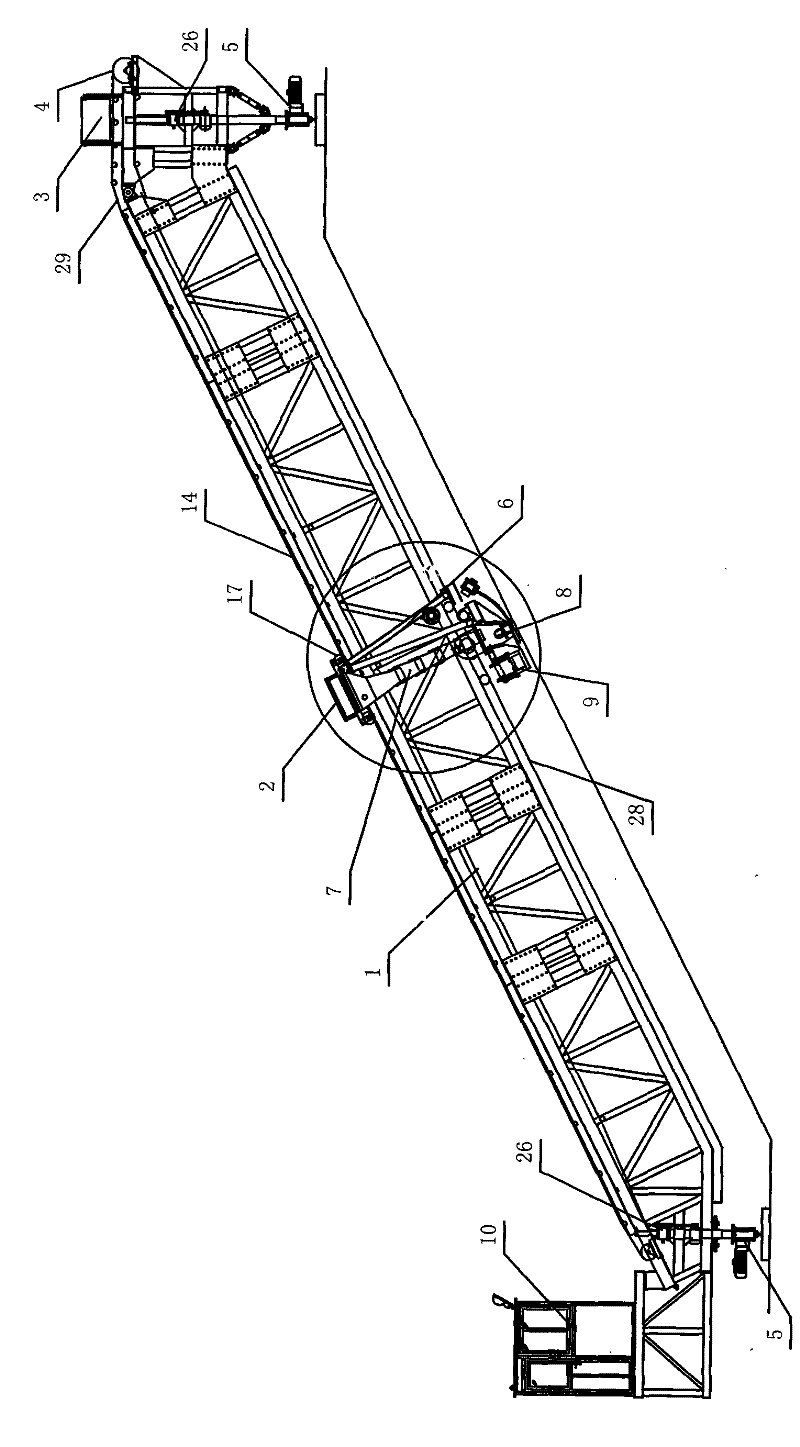

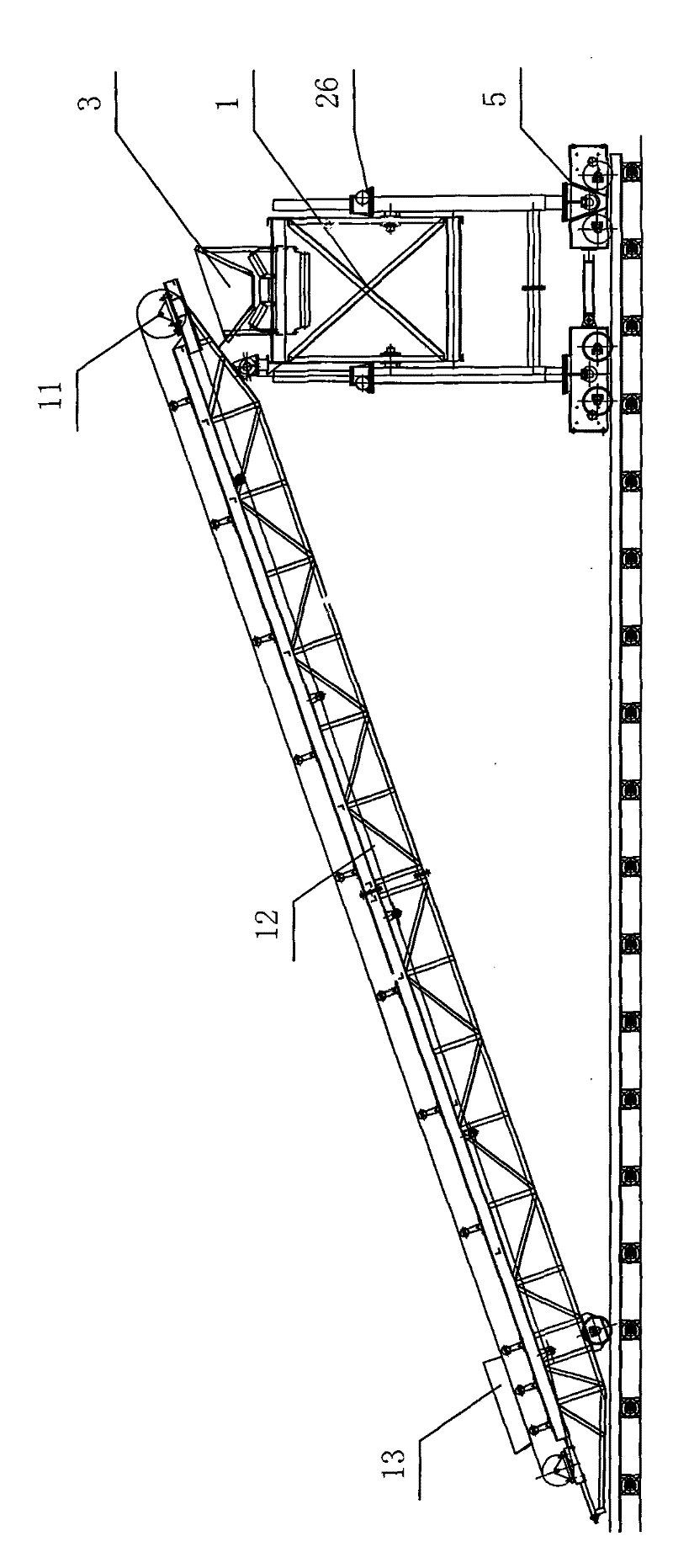

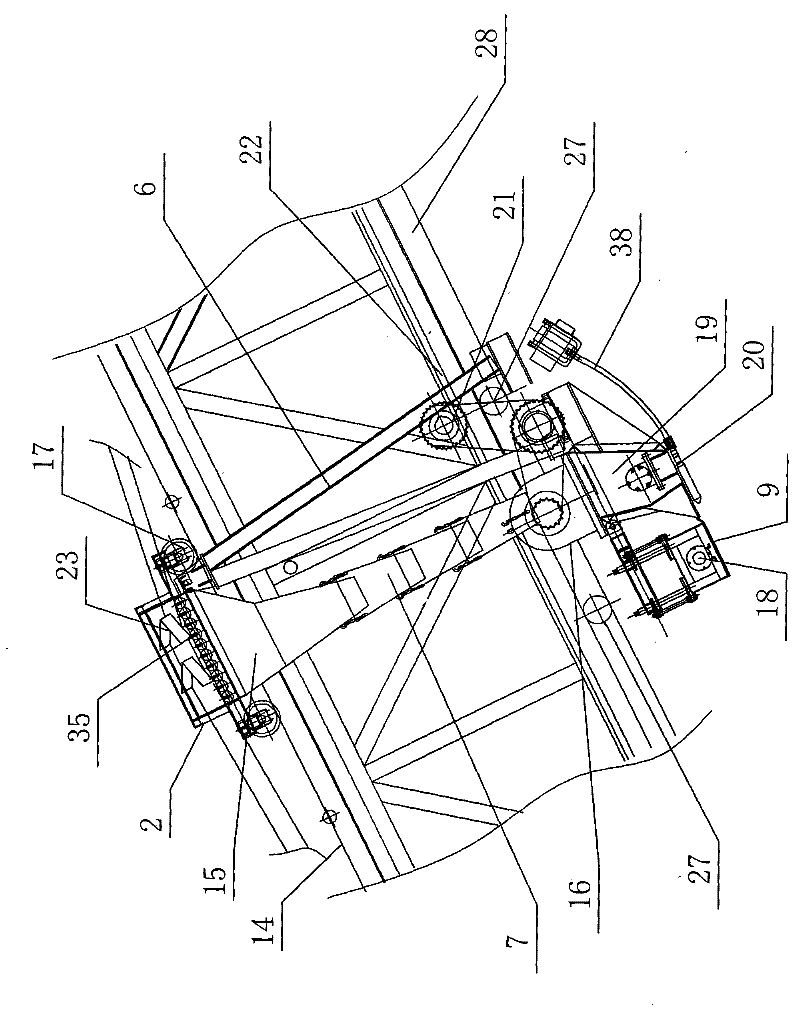

[0053] The present invention will be described in detail below in conjunction with embodiment, as appended figure 1 As shown, the present invention includes a main truss 1, a traveling mechanism 5 arranged at both ends of the main truss, a main receiving hopper 3 arranged at the top of the main truss 1, an electrical operation room 10 arranged at the bottom of the main truss 1, and a The main belt conveyor 4 and the conveying belt 29, the upper unloading vehicle 2 and the lower unloading vehicle 8 arranged on the main truss 1, the conveying system arranged on the upper unloading vehicle 2 and the lower unloading vehicle 8, The molding system on the feeding cart 8, as attached Figure 5 , 6 , shown in 10 and 11, the described upper unloading vehicle 2 is the upper unloading vehicle 2 arranged on the main truss 1 upper end track 14 through the upper traveling wheel 17, and the lower unloading vehicle 8 is arranged on the upper end rail 14 through the lower traveling wheel 27. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com