Excavating and supporting method of roadway containing quicksand layer

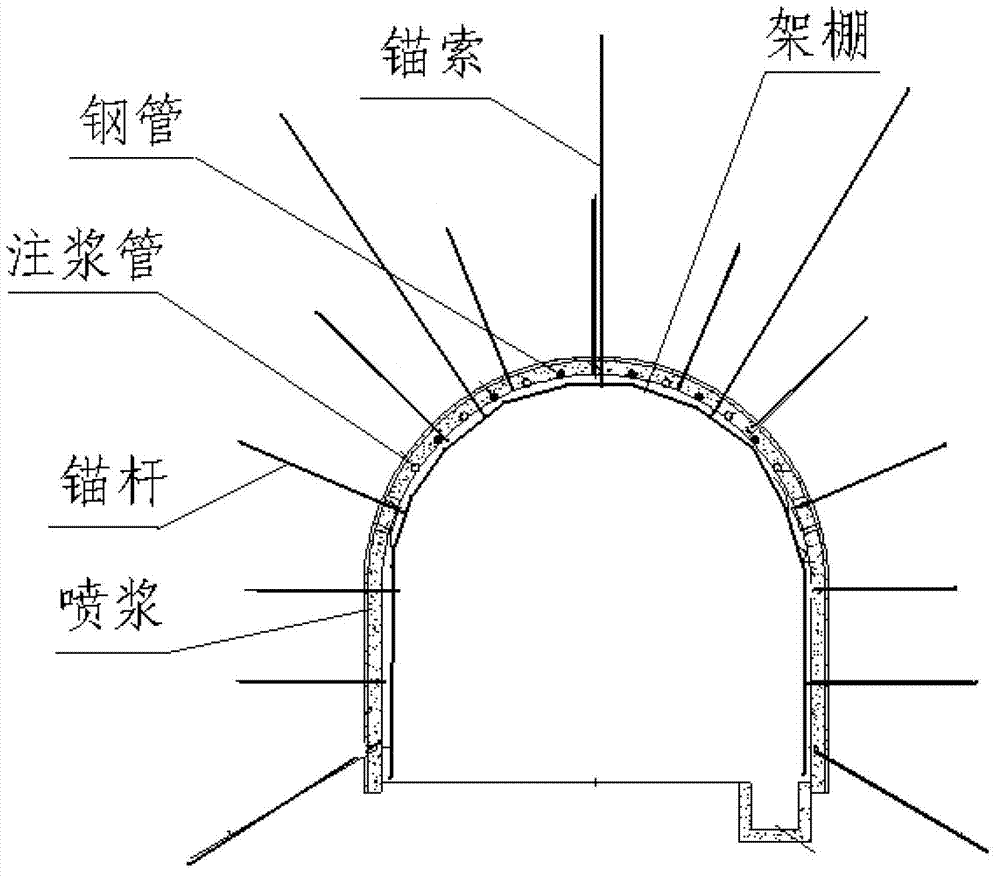

A roadway and quicksand technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as increased deformation of the roof, easy collapse of the quicksand layer, unsafe construction, etc., and achieve the effect of increasing support capacity and improving roadway deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Those skilled in the art can implement the technical solutions described with reference to the accompanying drawings and the summary of the invention.

[0013] The first step of the technical solution is described in detail below.

[0014] 1. The grouting pipe adopts a steel pipe with a diameter of 1 inch and a length of 3.5m. Several small holes are arranged in a plum blossom shape on the wall of the steel pipe, with a diameter of 6mm and a distance of 200mm. The head of the steel pipe is sharpened.

[0015] 2. The installation of the grouting pipe shall also meet the following requirements:

[0016] The grouting pipe spacing should be determined according to the surrounding rock conditions. When a single-layer arrangement is adopted, the spacing should be 200-400mm; when a double-layer arrangement is adopted, the spacing should be 400-600mm, and the upper and lower floors should be staggered.

[0017] The expansion angle of the grouting pipe should be determined acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com