Equipment for scraping surface of aluminum soldering material

A welding material and skin technology, which is applied in the field of aluminum welding material skin scraping equipment, can solve the problems of surface scratches and surface depressions, and achieve the effects of smooth wire feeding, simple structure and improved welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

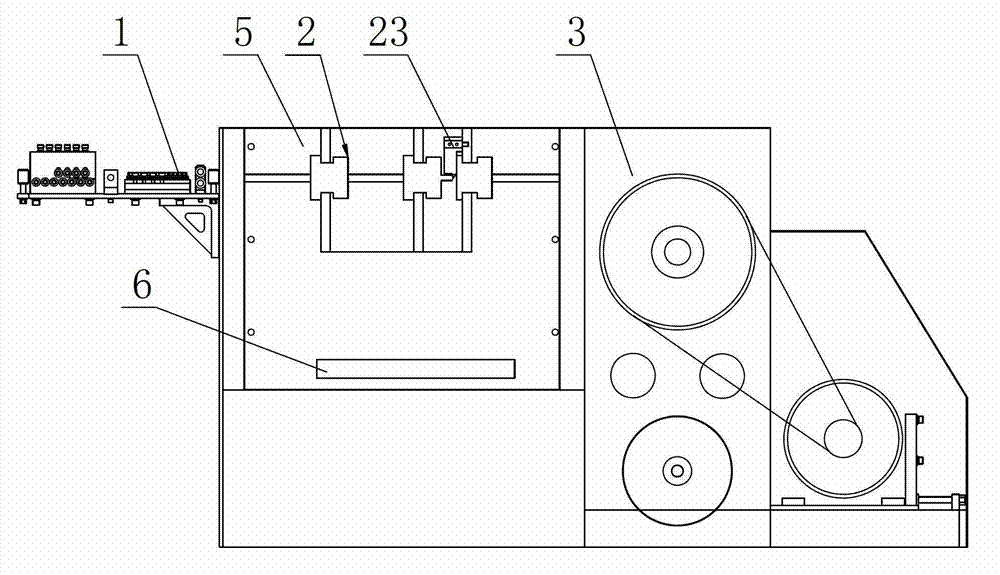

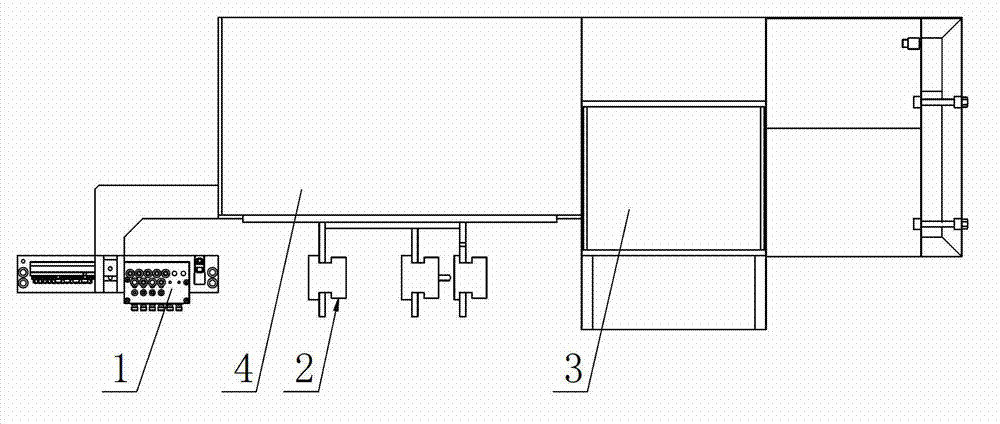

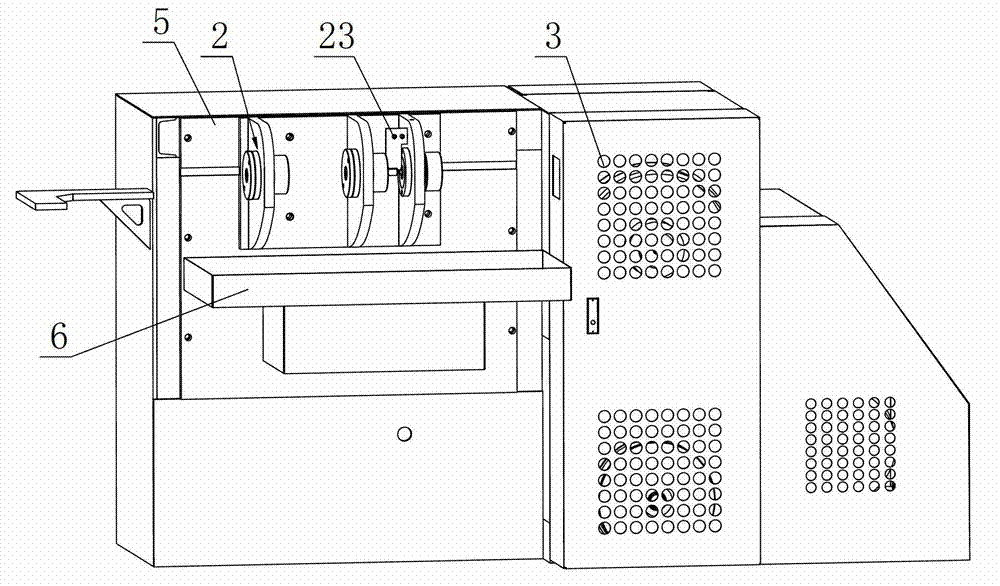

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0022] like Figure 1-6 As shown, the best embodiment of the aluminum welding consumable skin scraping equipment of the present invention includes a frame 5, on which a straightening wheel assembly 1, a scraping assembly 2 and a coiling assembly 3 are sequentially arranged, and the scraping assembly Be provided with waste box 6 directly below into 2. The scraping assembly 2 includes a compression part 21, a scraping part 22 and a cutter 23 between the compression part 21 and the scraping part 22 for cutting waste; the compression part 21 includes a compression mold 211 and a compression mold fixing device 3, and the compression mold 211 A compression hole 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com