Thickener, grease, method for producing thickener, method for producing grease, and greased bearing

A manufacturing method and a thickener technology, which are applied in the field of lubricating grease, can solve problems such as not being able to meet high-temperature and high-speed durability, achieve excellent high-temperature and high-speed durability, and improve high-temperature and high-speed durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Grease was prepared using base oil and thickener raw materials according to the compounding ratio shown in Table 1. It should be noted that, as shown in the lower part of Table 1, MORESCO-HILUBE LS150 (150mm 2 / s(40℃)), the ester oil is HATCOL H3855 (148mm 2 / s(40℃)), the ionic liquid uses OMI-TFSI (91mm 2 / s(20℃)).

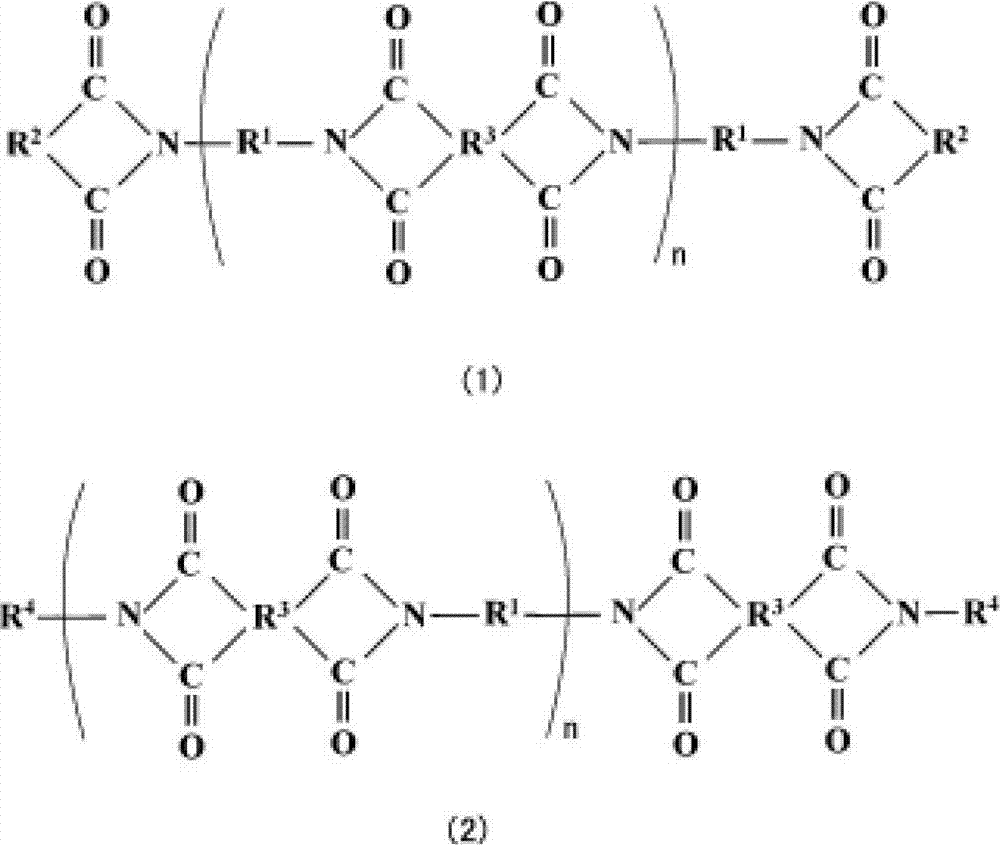

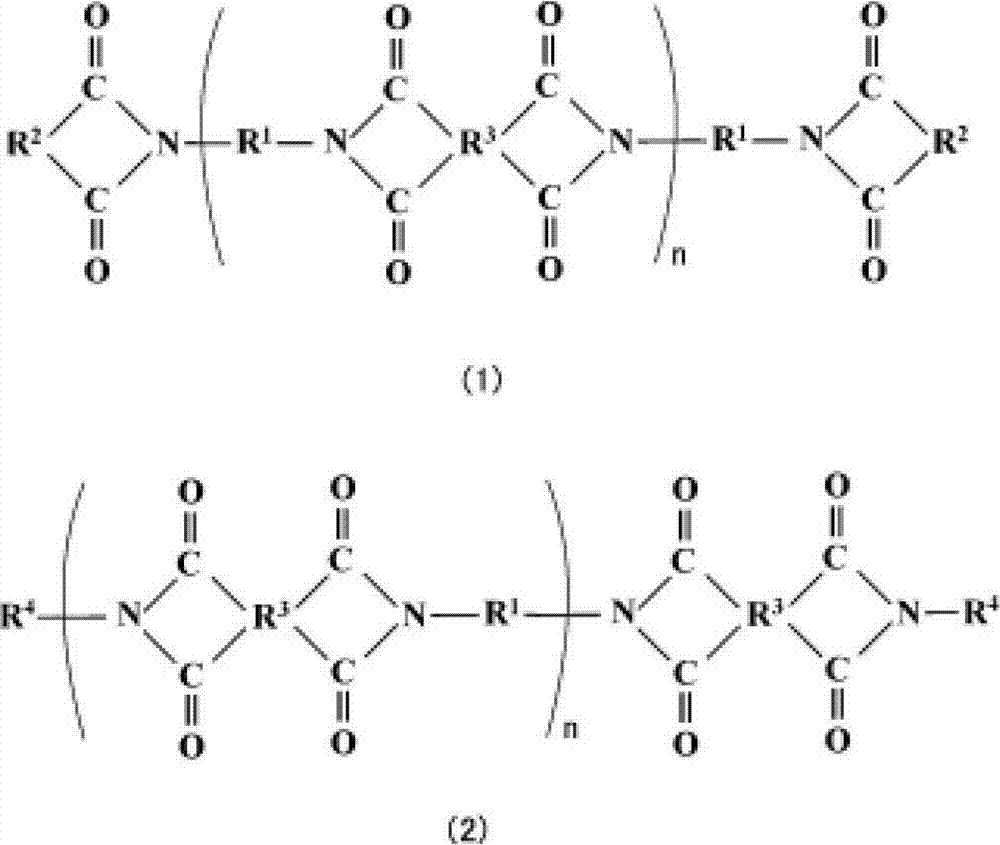

[0101] MDI (diphenylmethane-4,4'-diisocyanate) and phthalic anhydride are dissolved in acetone and dimethylacetamide solvent, and triethylenediamine is added as a catalyst. In terms of molar ratio, the blending amount of phthalic anhydride is twice that of MDI.

[0102] The mixed solution was reacted at 50° C. for 24 hours, and the obtained reaction product was washed with a large amount of acetone and dried to obtain a powdery compound. Confirmed by infrared spectroscopic analysis: the compound is at about 1780cm -1 There is imide ring based absorption.

[0103] All the obtained powdery compounds were added to 50 g of ether oil, stirred, and then ro...

Embodiment 2~ Embodiment 6

[0105] Grease was prepared using base oil and thickener raw materials according to the compounding ratio shown in Table 1.

[0106] The MDI and acid anhydride are heated and dissolved in the base oil, and triethylenediamine or tetraethylenediamine is added as a catalyst. In terms of molar ratio, the compounding amount of acid anhydride is twice that of MDI.

[0107]The base oil solution was reacted at 90-150°C for 10 hours, and the resulting base grease was passed through a roll mill to obtain a semi-solid grease. In addition, in Example 5, after adding sodium sebacate as an antioxidant and stirring, it passed the roll mill. Table 1 shows the measurement results of the mixed consistency of the obtained grease. In addition, the following high-temperature, high-speed durability tests were performed, and the results are shown in Table 1 together.

Embodiment 7

[0109] Grease was prepared using base oil and thickener raw materials according to the compounding ratio shown in Table 1.

[0110] Dissolve 21.9 g of DDE (4,4'-diaminodiphenyl ether) in 100 g of dimethylacetamide solvent, cool the solution to 0°C, and add 11.9 g of powdered PMDA (pyromellitic anhydride) to the solution. g, a clear solution was obtained. In terms of molar ratio, the compounding amount of DDE is twice that of PMDA. 16.2 g of phthalic anhydride was added to this solution, and it stirred well. Then, the temperature of the solution was raised to 120° C., and it was allowed to react at this temperature for 1 hour, whereby a precipitate was obtained. The precipitate was washed with a large amount of acetone and dried to obtain a powdery compound. Confirmed by the results of infrared spectroscopic analysis: the compound is at about 1780cm -1 There is imide ring based absorption.

[0111] All the obtained powdery compounds were added to 50 g of ether oil, and rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com