Sliding rail tool-installation-free front support for server

A mounting bracket, tool-free technology, applied in the direction of support structure installation, rack/frame structure, etc., can solve the problems of inconvenient installation work and low work efficiency, and achieve the effect of simple, effective, convenient tool-free installation and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

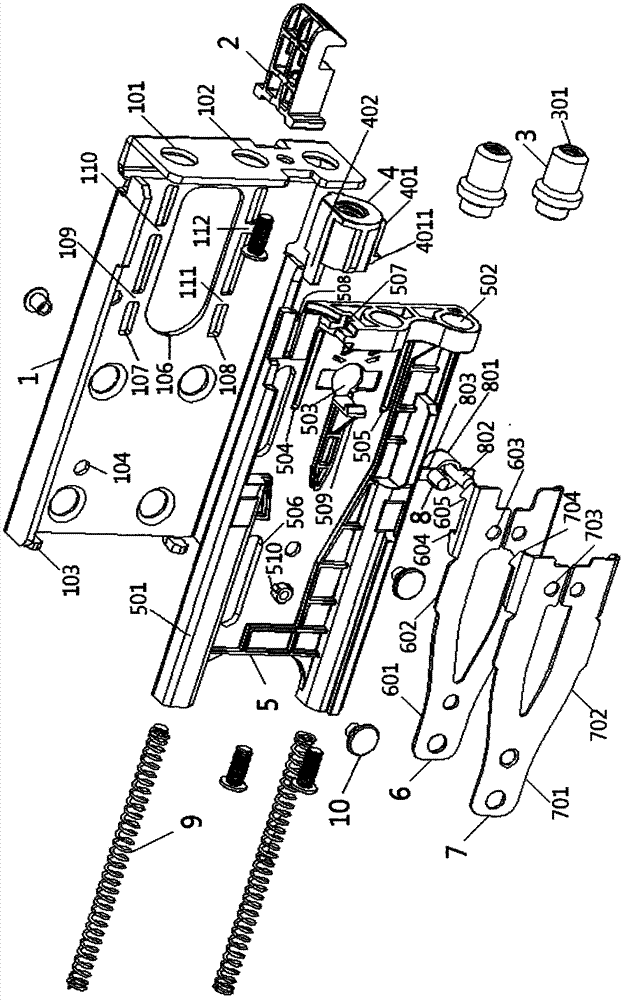

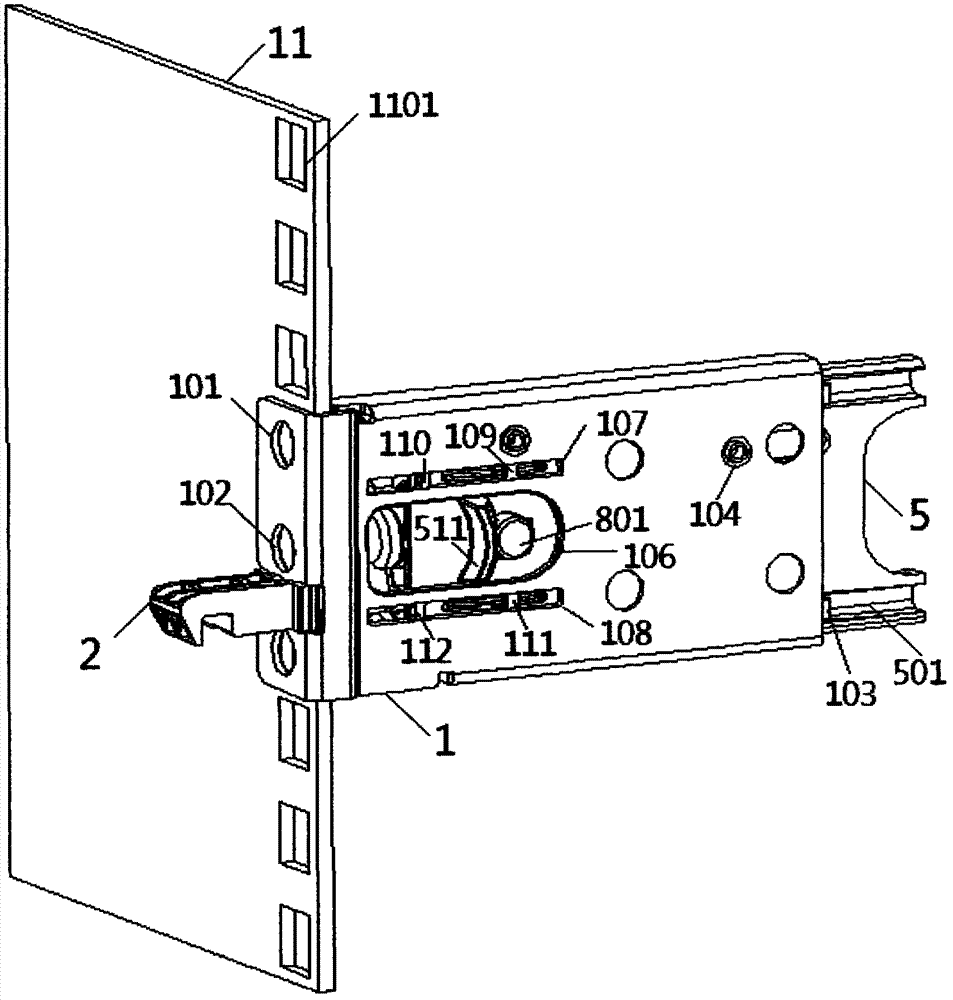

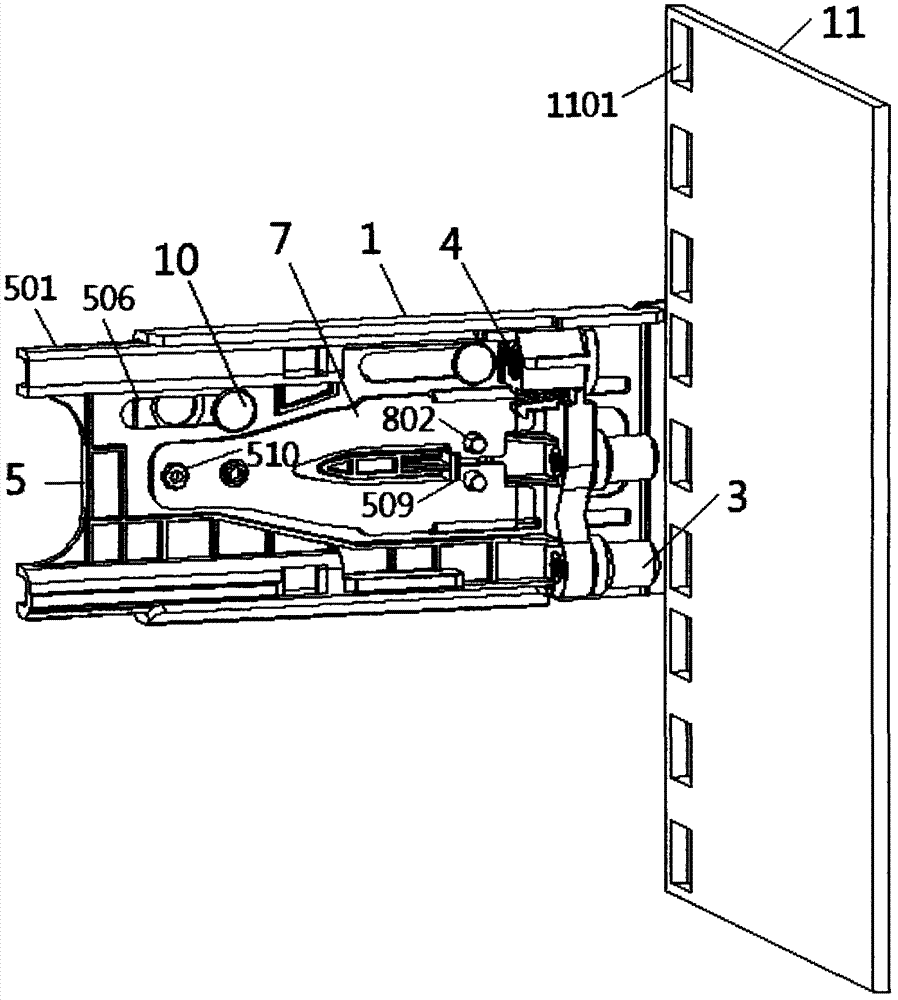

[0026] see figure 1 , figure 2 , image 3 , Figure 4 As shown, a front bracket for server slide rail tool-free installation, which includes a slide rail front mounting bracket 1, a hook 2, a pair of rack positioning posts 3, a bracket slider 5 and a first position locking spring 6;

[0027] One end of the front mounting bracket 1 of the slide rail is provided with a pair of spring stoppers 103, and the other end is provided with a vertical bending surface of the bracket. The hook 2 is fixedly connected to the vertical bending surface of the bracket, and the bracket is vertically bent. Two positioning post holes 102 are opened on the curved surface, and a button displacement groove 106 is opened on the panel of the front mounting bracket 1 of the slide rail, and first tooth grooves 107 are respectively opened at the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com