Stator punched plate of single-phase direct current brushless motor

A stator punching, DC brushless technology, applied in electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc. Simple and reasonable structure, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

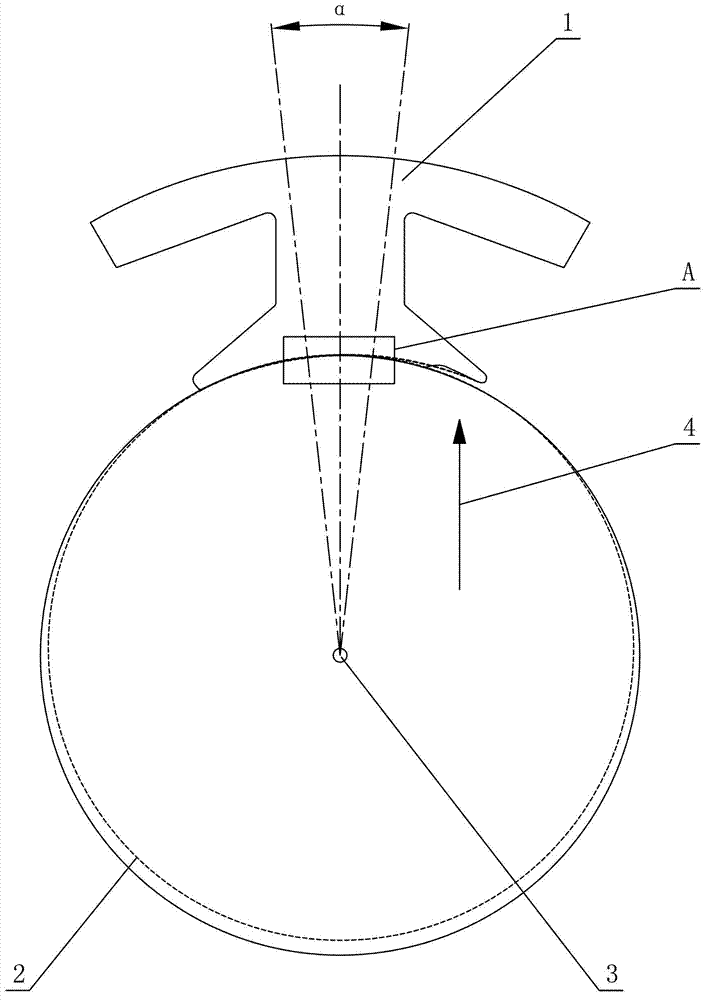

[0016] see figure 1 - Figure 4 , a stator punch of a single-phase DC brushless motor, including a stator punch 1, the stator punch 1 is integrally formed, and is provided with six punch slots 5, and the inner ports of the adjacent punch slots 5 are not in phase Connected to the spaced shape, the inner arc of the stator punching plate 1 is transitioned with the offset arc 2, the number of which is the same as the number of rotor poles and the number of punching slots 5, and the offset direction 4 of the offset arc 2 points to the corresponding stator tooth .

[0017] Among them, the radius R of offset arc 2 and the inner arc radius R of the stator before offset 0 , the radius r of the center of the offset arc 2 and the offset circle 3, the angle α of the center offset of the offset arc 2 based on the central axis, the intersection of the offset arc 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com