Numerical control machining cutter path generation method based on double helix space filling curves

A space filling curve, filling curve technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of Hilbert filling curve changing direction, arc research, etc., to improve the quality of the machined surface, excellent machining quality, and achieve smooth transition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0031] This embodiment provides a method for generating a CNC machining tool trajectory based on a double-helix space-filling curve, including the following steps:

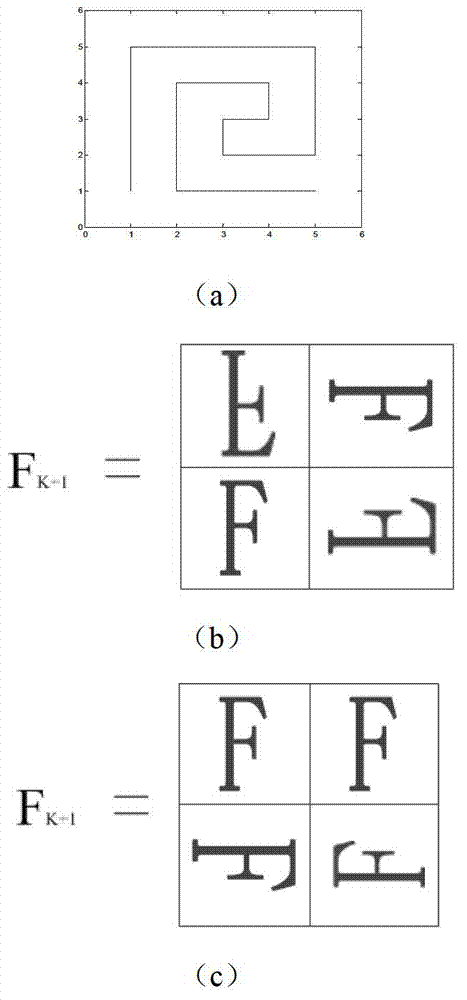

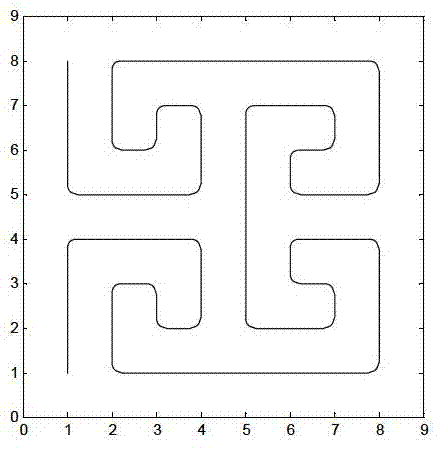

[0032] Step 1. Determine the order of the filling curve according to the residual height and surface shape, and generate a double helix filling curve that meets the required order on the two-dimensional plane;

[0033] Step 2, improving the corner part of the tool path to optimize the tool path;

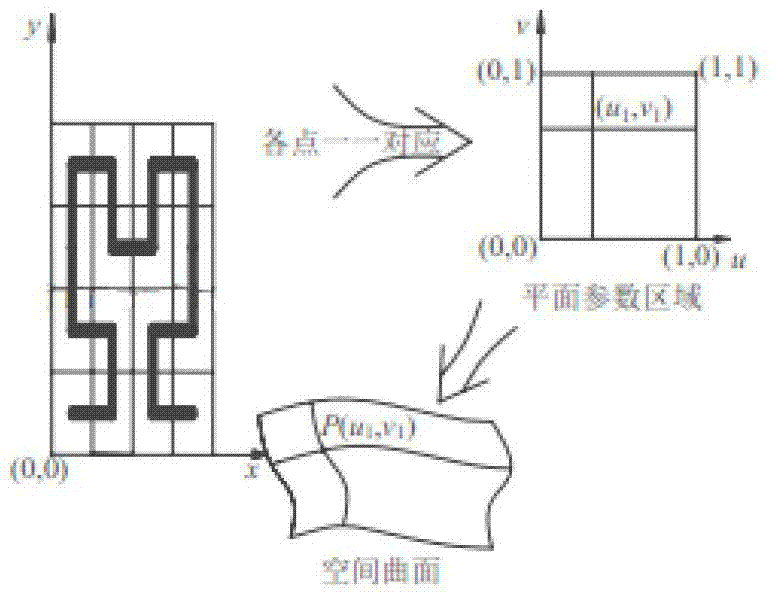

[0034] Step 3, according to the mapping principle, the two-dimensional filling curve is mapped to the space surface to obtain the tool trajectory in NC machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com