Preparation method of colorful substrate, colorful substrate and semi-reflection semi-penetration liquid crystal display device

A color film substrate and color film technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of increasing the manufacturing cost of color film substrates, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The actual light-passing holes on the color filter substrate prepared by the method for preparing the color filter substrate of the present invention are the light-passing holes of the color filter layer formed by the mask plate of the color filter and the light hole filling pattern of the black matrix layer of the black matrix layer. Forming. From the process sequence: you can do the black matrix (BM) layer first, and then do the red (R), green (G), and blue (B) color film layers.

[0031] The method for preparing a color filter substrate provided by the present invention may specifically include the following steps:

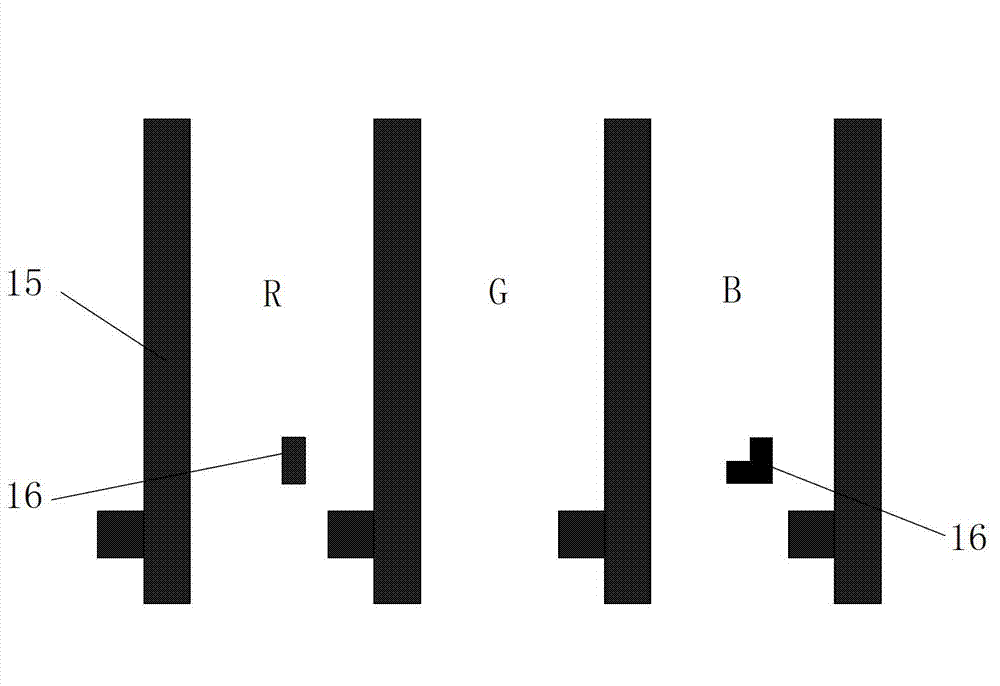

[0032] S1. Prepare a black matrix mask, and set a specific light hole filling pattern on the black matrix mask for specific color sub-pixels.

[0033] A black matrix layer is formed through the black matrix mask.

[0034] S2. The mask plate for preparing the color film, the mask plate of the color film prepared for the sub-pixels of different colors is provided...

Embodiment 2

[0050] The present invention also provides a color filter substrate, which can be specifically prepared by the method described in the first embodiment.

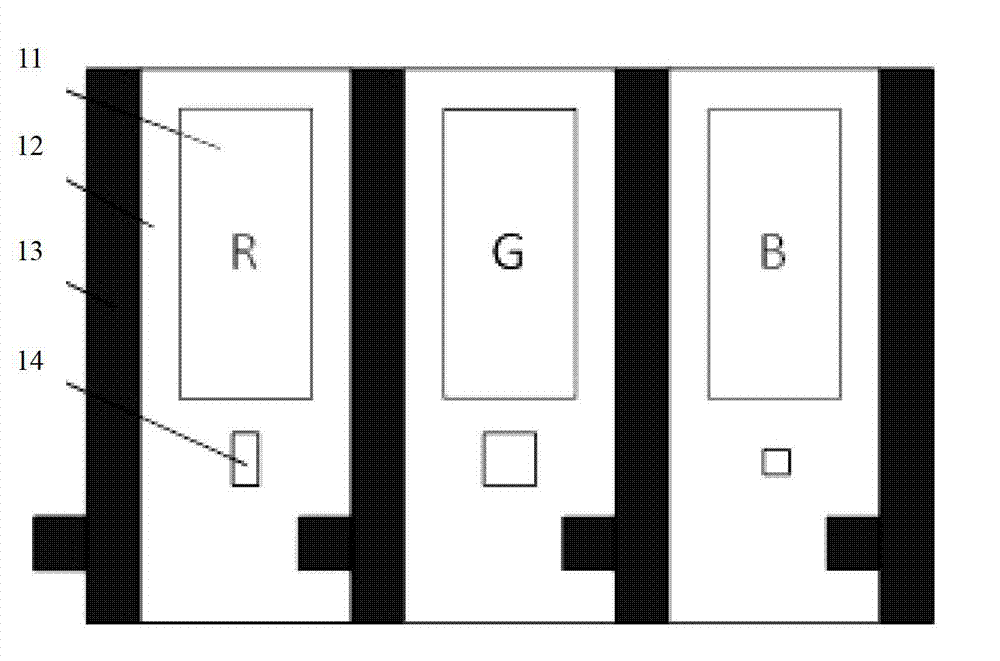

[0051] The color filter substrate of the embodiment of the present invention includes a color filter layer and a black matrix layer, wherein the light hole 14 of the sub-pixel color filter of a specific color has a specific black matrix light hole filling pattern 16'.

[0052] In order to facilitate the understanding of those skilled in the art, the following combination Image 6 The structure of the color filter substrate according to the embodiment of the present invention is specifically described.

[0053] The color filter substrate described in the embodiment of the present invention can be specifically applied to a transflective liquid crystal display device.

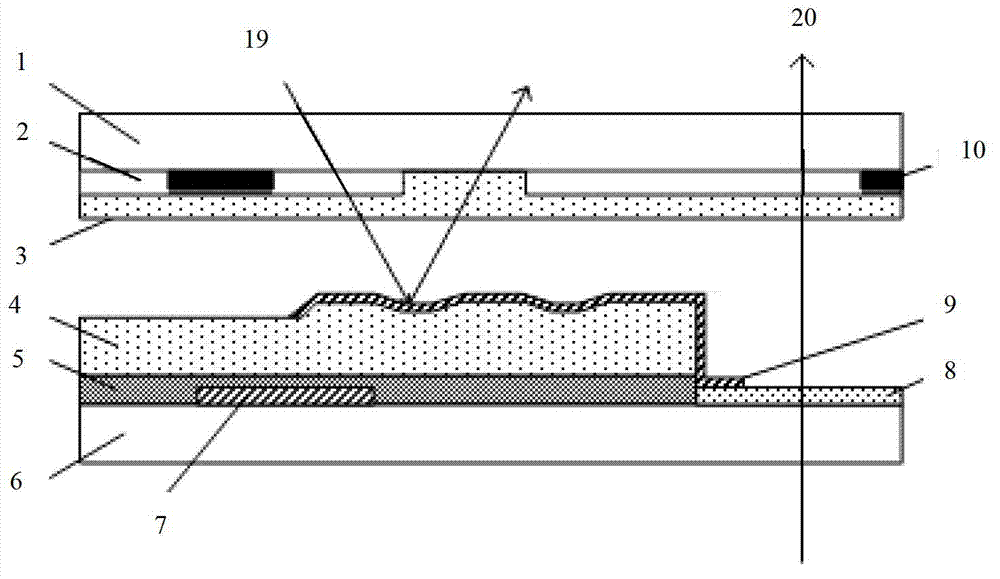

[0054] The color filter substrate (also referred to as the upper substrate) may specifically include an upper glass substrate 1, a black matrix layer located under the ...

Embodiment 3

[0064] The present invention also provides a transflective and transflective liquid crystal display device, which includes the color filter substrate described in the second embodiment. The transflective liquid crystal display device in the embodiment of the present invention may specifically be a display device such as a TV, a computer monitor, and a mobile phone.

[0065] In order to facilitate the understanding of those skilled in the art, the following combination Image 6 The structure of the transflective liquid crystal display device according to the embodiment of the present invention will be specifically described.

[0066] The transflective liquid crystal display device according to the embodiment of the present invention specifically includes a display panel, and the display panel includes an upper substrate (also called a color filter substrate) and a lower substrate (which may be a TFT array substrate).

[0067] The lower substrate may specifically include a lower glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com