Method for quickly producing water vapor and steamed furnace using same

A water-vapor and fast technology, applied in the field of kitchen appliances, can solve the problems of steaming steamed buns, long cooking process, difficult to meet the needs of modern life, slow start-up of electric heating steam furnaces, etc., and achieves simple structure, easy popularization and application, and reasonable and ingenious design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

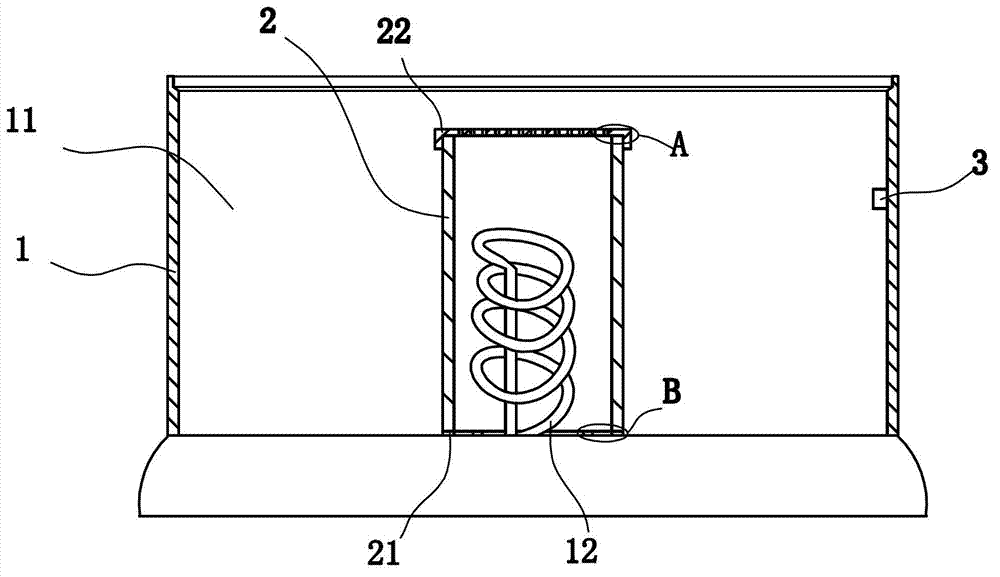

[0026] Example: see figure 1 , figure 2 with image 3 , The present invention is a method for quickly generating water vapor, which includes the following steps:

[0027] (1) Prepare a furnace body 1, which is provided with a cavity 11 containing a water body, and a heating element 12 is provided in the cavity 11;

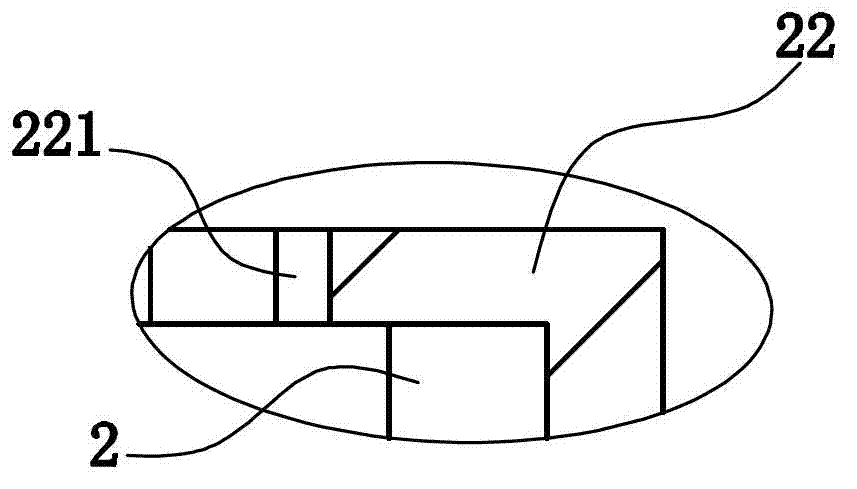

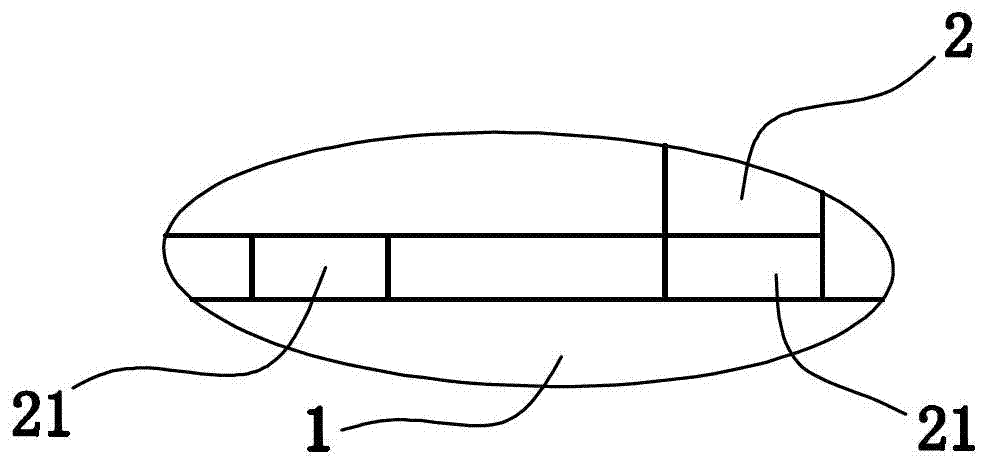

[0028] (2) Prepare a water divider 2 made of heat insulating material. The water divider 2 is cylindrical. The bottom end of the water divider 2 is provided with a number of small protrusions 21. The top of the water divider 2 is fixed with several The top cover 22 of the hole 221 covers the water divider 2 on the heating element 12. The top height of the water divider 2 is greater than the top height of the heating element 12, and the small protrusion 21 makes the bottom of the cavity 11 and There is a gap between the bottom ends of the water body 2 to facilitate the circulation of the water body loaded in the cavity 11;

[0029] (3) A water level sensor 3 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com