Control method and control device of slow speed type electric valve

A technology of electric valve and control method, applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problems of increasing weight, increasing production cost, increasing transportation cost, etc., to avoid burnout and avoid water hammer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

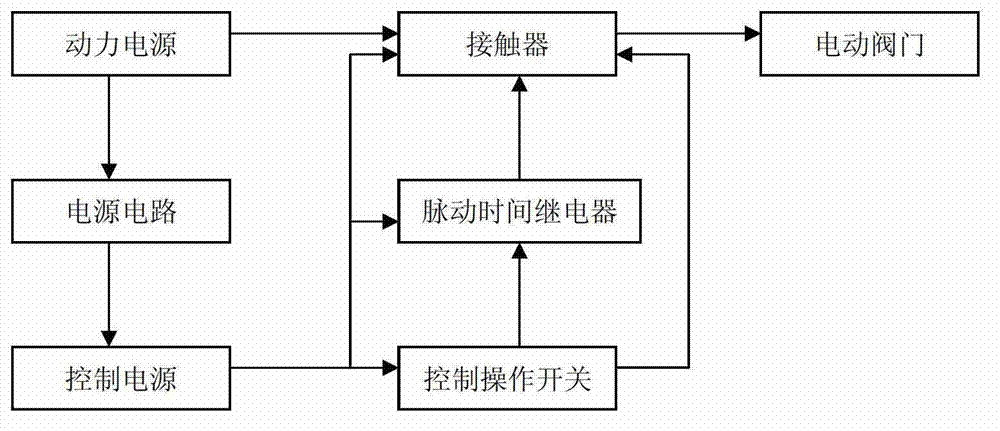

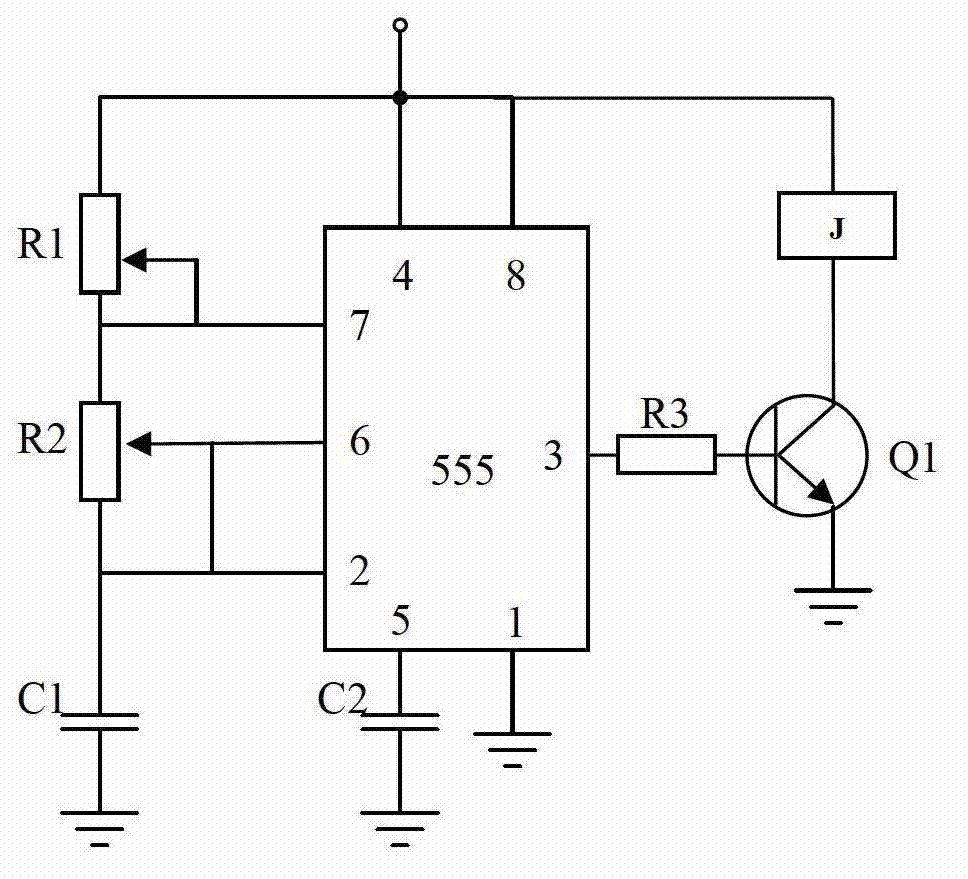

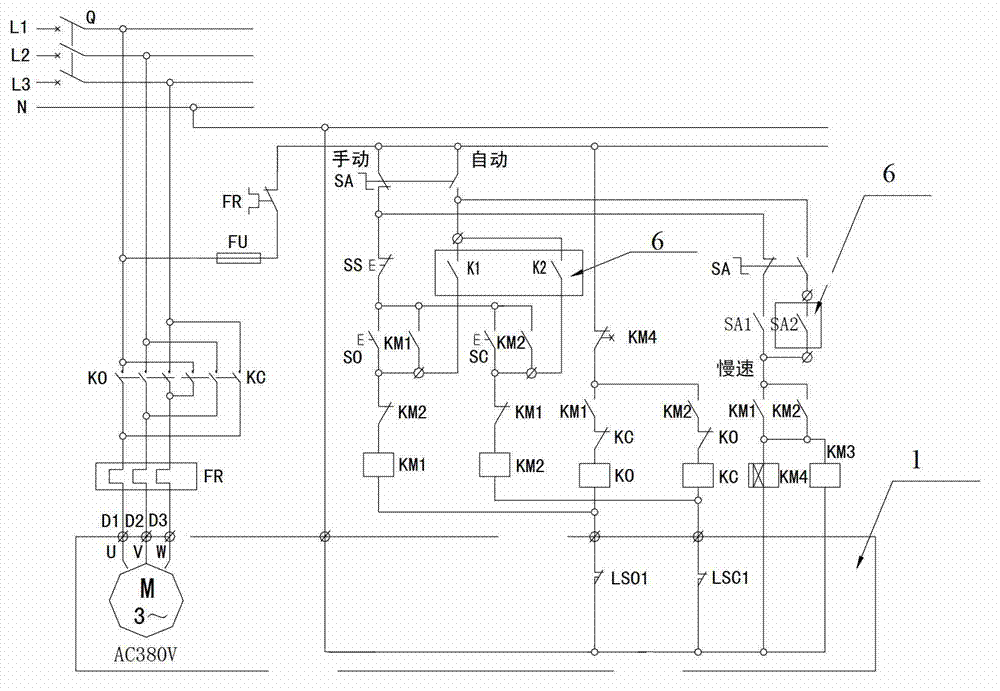

[0021] The present invention adds a pulsating time relay in the control box of the electric valve to reduce the speed of opening and closing of the electric valve (such as figure 1 ), the control box of the electric valve includes power supply, control power supply, control operation switch and relay. Wherein, the control power supply is a low-voltage DC power supply, which provides working power for the control operation switches, relays and the like. The control power is obtained from the power supply through the power circuit. The power circuit is a step-down and rectification circuit, which steps down and rectifies the AC power supply to obtain a low-voltage DC control power supply. The control operation switch controls the power supply connected to the motor of the electric valve through the relay, so as to open and close the valve. In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com