Truss structure of wind turbine generator set

A wind turbine, truss-type technology, applied to wind turbine components, wind engines, wind power generation, etc., can solve the problems of being easily affected by weather and climate changes, large construction volume, and long cycle, so as to shorten the construction cycle and reduce the Construction time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

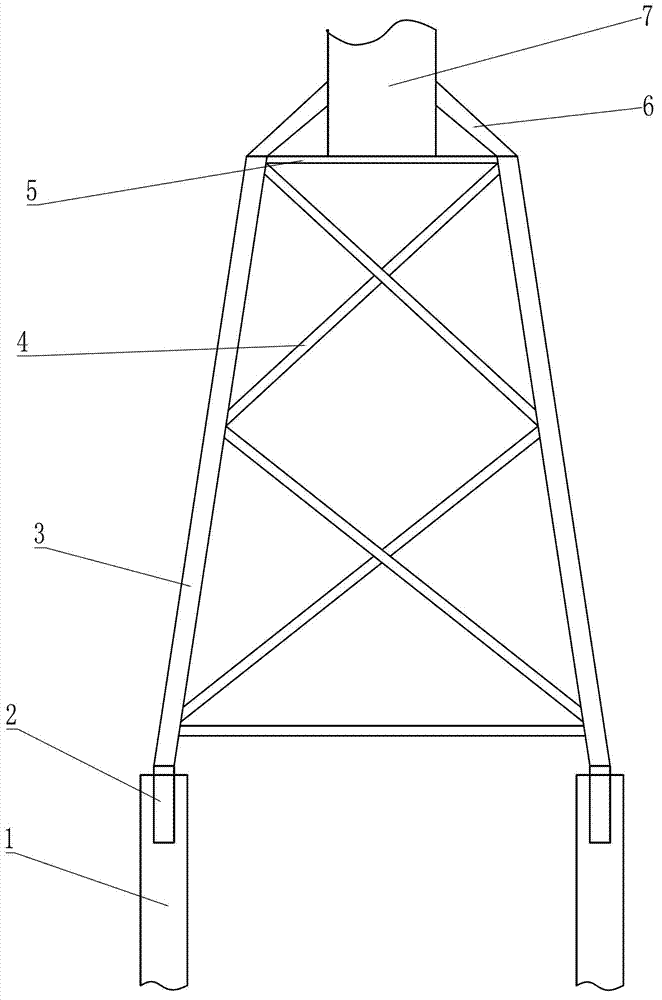

[0019] Such as figure 1 , figure 2 As shown, the structure of the truss-type wind power generation unit includes a steel pipe pile 1 extending into the bearing layer below the seabed, an insertion section 2 partially inserted into the upper end of the steel pipe pile 1, and a jacket welded to the upper end of the insertion section 2. Legs 3, the supporting steel pipes 4 welded between the jacket legs 3, the tower platform 5 arranged on the jacket legs 3 and the supporting steel pipes 4, welded to the tower platform 5, the jacket legs 3 and the supporting steel pipe 4 form a truss structure, and the diagonal brace 6 is connected with the tower 7 placed on the tower platform 5, as the present invention In one embodiment, the brace 6 is connected to the tower tube 7 placed on the tower platform 5 by welding, so that the tower tube 7 is installed more firmly and has a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com