Cantilever type coal cutter rocking arm

A coal shearer and cantilever type technology, which is applied in the direction of earthwork drilling, cutting machinery, driving devices, etc., can solve the problems of increasing the top control area of the support, unsatisfactory cooling effect, and high temperature of the rocker oil tank, so as to reduce the control Top area, lower temperature, less leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

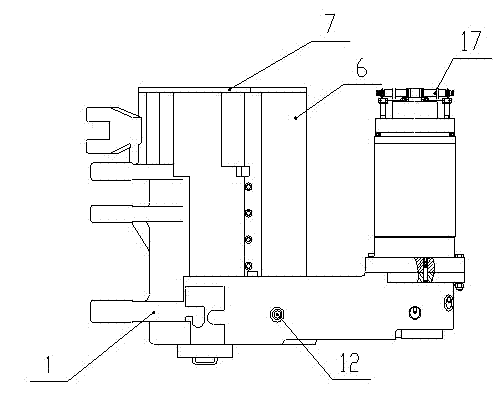

[0014] Such as Figure 1 to Figure 4 As shown, the present invention includes rocker arm housing 1, cutting motor 2, cable 3, oil pipe 4, height adjustment gear pump 5, gear transmission system 8, clutch 9, internal spraying system 10, external spraying system 11, fuel filler 12 And the screw plug at the oil discharge port 13, also includes the motor shield 6 and the motor shield 7, the external spray system 11 includes the water channel in the rocker housing 1, the spiral cooling water pipe 14 and the rocker housing 1 The nozzle of the nozzle, the spiral cooling water pipe 14 is located in the gear chamber where the gear transmission system 8 is located; the internal spray system 10 includes the water channel on the rocker shell 1, the internal spray waterway device 16, the water pipe 17 and the nozzle on the drum; The cutting motor 2 is fixed on the rocker arm housing 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com