Split robot with suction cup

A robot and split-type technology, applied in the direction of motor vehicles, window cleaning, cleaning equipment, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of reducing the length of the fuselage, compact structure, and shortening the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

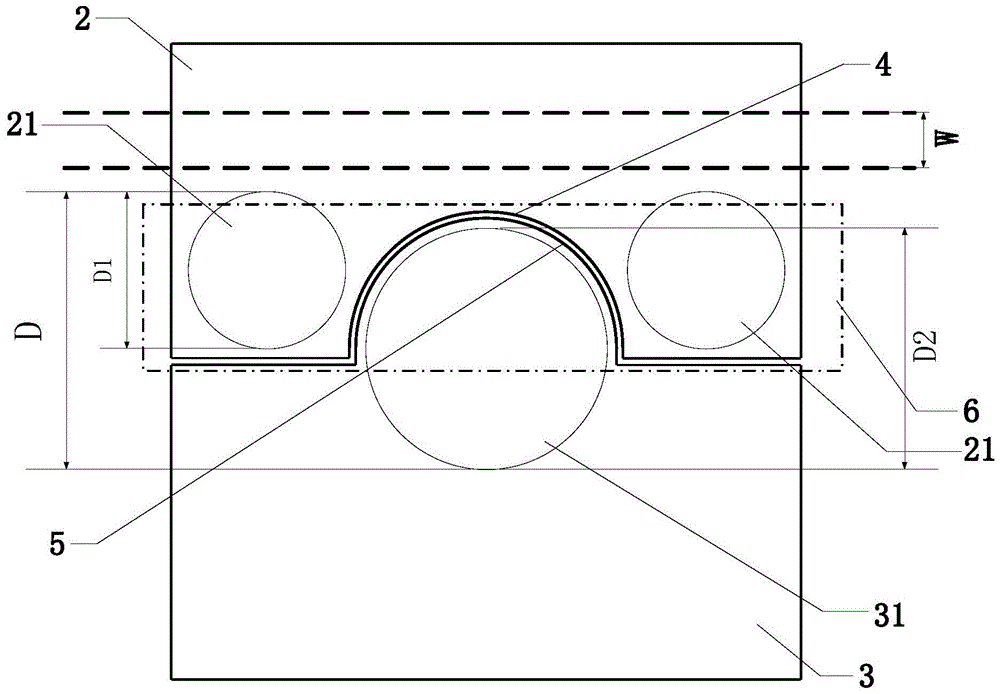

[0016] The split robot in the embodiment of the present invention is provided with a front body 2 and a rear body 3 . The connecting mechanism and the actuating mechanism between the front body 2 and the rear body 3 can be arranged in a manner known in the art, and will not be repeated here. like image 3 As shown, the front body 2 is provided with at least one concave / convex portion 4 facing the rear body 3, and the rear body 3 is provided with at least one convex / concave portion 5 facing the front body 2 (for ease of illustration, image 3 Only one convex / concave part 5 is shown in the figure), the concave / convex part 4 matches the shape of the corresponding convex / concave part 5, so that when the front body 2 and the rear body 3 are closed, the front body in the forward direction of the split robot The rear side of 2 and the front side of rear body 3 envelop each other, forming such as image 3 The matching area 6 shown by the dotted line is similar to that of gears meshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com