Method for opening sand-blasting hole of horizontal well by coiled tubing

A technology for sandblasting holes and horizontal wells, which is applied in the valve device of wellbore/well, production fluid, earthwork drilling, etc., can solve the problem that the sliding sleeve cannot be opened normally, save manpower, improve construction efficiency, and structural principle simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

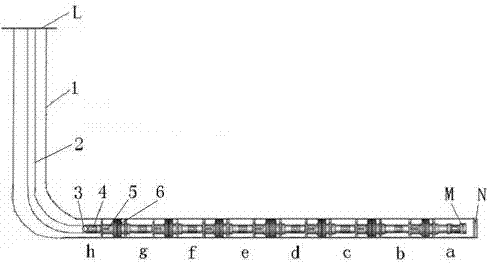

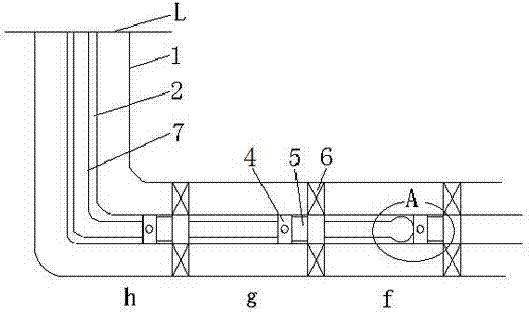

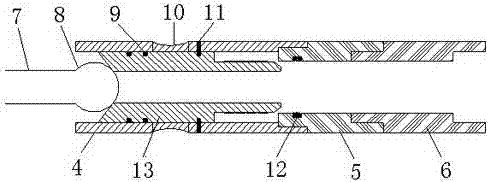

[0019] Such as Figure 1~5 As shown, the present invention is a method for opening the sandblasting hole 10 of a horizontal well by using coiled tubing 7. In the multi-layer segmental fracturing string of a horizontal well, multiple groups of sandblasting tubes 4, lower joint 5 and packer 6, and use packer 6 to separate each interval a~h. Wherein: each sandblasting cylinder 4 is respectively provided with two split sandblasting holes 10, the inside of the sandblasting cylinder 4 is sleeved with a sliding sleeve 13, and the sliding sleeve 13 is fixed on the inner wall of the sandblasting cylinder 4 by pins 11 and The sandblasting holes 10 of each layer section a~h are closed, and a sealing ring 9 is arranged between the sliding sleeve 13 and the sandblasting cylinder 4. The sliding sleeve 13 can slide toward the bottom M of the pipe string in one direction under the action of external force to open The sandblasting holes 10 on the sandblasting cylinder 4 are used for fracturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com