Process for preparing health care textile strand impregnating solution

A preparation process and impregnating liquid technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of difficult batch production, complicated preparation process, and low production efficiency, and achieve the effects of long-lasting timeliness, excellent comprehensive performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

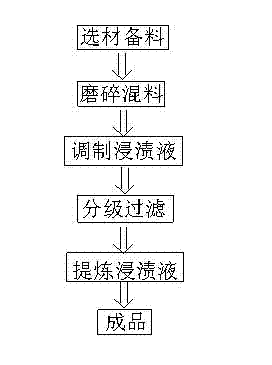

Image

Examples

Embodiment 1

[0017] The specific preparation process of the above-mentioned health care yarn dipping solution is as follows:

[0018] a) Material selection and preparation, the main raw materials and their percentages of the impregnating liquid are as follows: 4% angelica, 4% almond, 8% kudzu root, 5% raw land, 4% safflower, 5% jue sheng, and 6% fenugreek , Chuan Gong 3%, buffalo horn 20%, mica powder 13%, tourmaline 28%; after the raw materials are selected, they are first washed with water to remove impurities, and then dried in the sun for later use;

[0019] b) Grinding and mixing, firstly, chop the treated impregnating liquid raw materials; then, use ball milling or ultrasonic pulverization to obtain powder; then, use a 300-mesh sieve to screen the powder to obtain the particle size 300-400 purpose functional powder;

[0020] c) Prepare the impregnation solution, add the prepared functional powder into the reaction kettle, add a sodium carbonate solution with a concentration of 12g / L...

Embodiment 2

[0024] The specific preparation process of the above-mentioned health care yarn dipping solution is as follows:

[0025] a) Material selection and preparation, the main raw materials of the impregnation solution and their percentage content are as follows: 5% angelica, 4% almond, 9% kudzu root, 6% raw land, 4% safflower, 6% juesheng, and 7% fenugreek , Chuan Gong 4%, buffalo horn 20%, mica powder 12%, tourmaline 25%; after the raw materials are selected, they are first washed with water to remove impurities, and then dried in the sun for later use;

[0026] b) Grinding and mixing, firstly, chop the treated impregnating liquid raw materials; then, use ball milling or ultrasonic pulverization to obtain powder; then, use a 300-mesh sieve to screen the powder to obtain the particle size 300-400 purpose functional powder;

[0027] c) Prepare the impregnation solution, add the prepared functional powder into the reaction kettle, add a sodium carbonate solution with a concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com