Button delivery rocker arm modification mechanism of button attaching machine tool

A technology for machine tools and buttons, which is applied in the field of garment processing machinery, can solve the problems that the moving block is easy to get stuck, easy to lose stability, and affect the service life of the rotating motor, so as to achieve low assembly difficulty and debugging difficulty, reduce production and maintenance costs, and improve The effect of mechanical assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

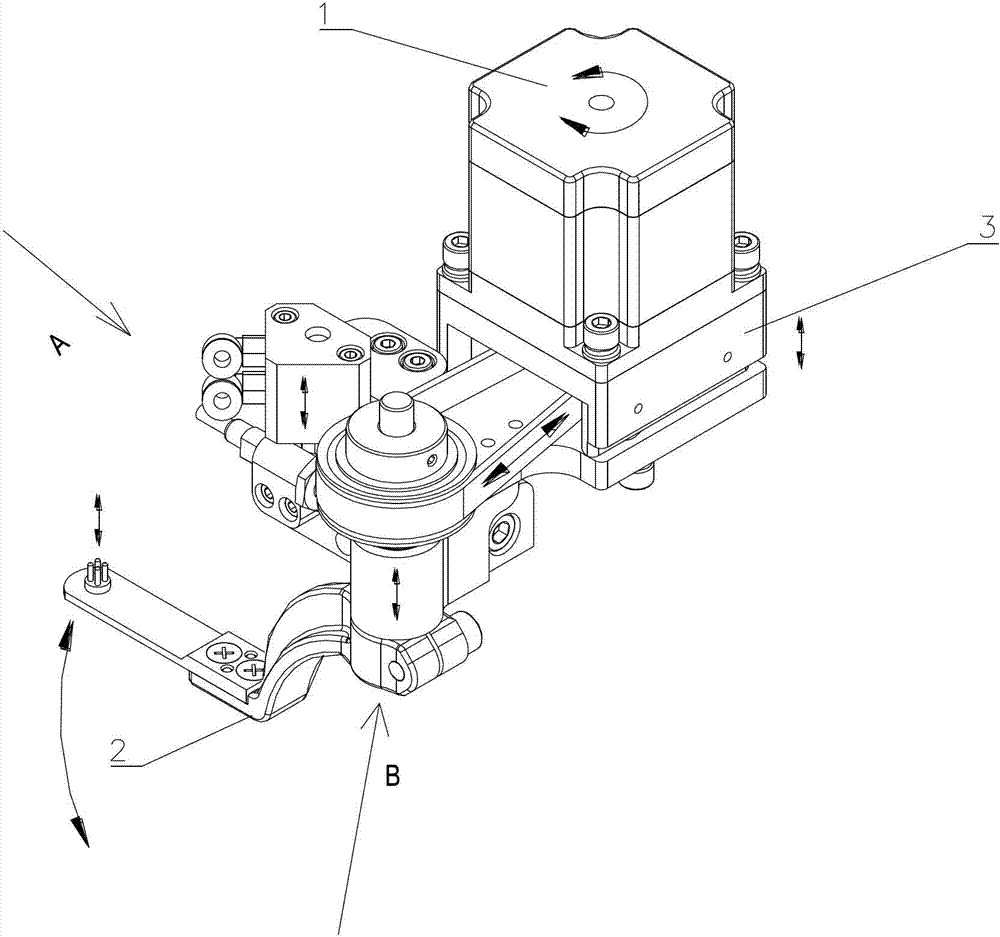

[0020] as attached figure 2 , 3 , 4 and 5, an improved mechanism for sending button rocker arm of a button sewing machine, comprising a stepper motor 1 and a rocker arm 2, the stepper motor 1 is vertically mounted on the pedestal 3, and the output shaft of the stepper motor 1 is vertical Downward, wherein, the driving wheel 3 is housed on the output shaft of the stepper motor 1, the driving wheel 4 is connected with the driven wheel 6 through the synchronous belt 5, the output shaft of the driven wheel 6 is connected with the rocking arm rotating shaft 201, and the rocking arm rotating shaft 201 Installed in the rocker arm rotating seat 202, the installation part of the rocker arm rotating seat 202 is fixed on the output end of the threaded rod of the sliding cylinder 7, the sliding cylinder 7 is fixed on the cylinder base 8, and the threaded rod of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com