Relief printing plate structure

A technology for printing letterpress and graphics, applied to printing plates, printing, printing machines, etc., can solve problems such as abnormal orientation of liquid crystal molecules, uneven surrounding colors, affecting product quality and yield, etc., to improve width and thickness, and reduce vibration And boundary pressure, guarantee the effect of printing and display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

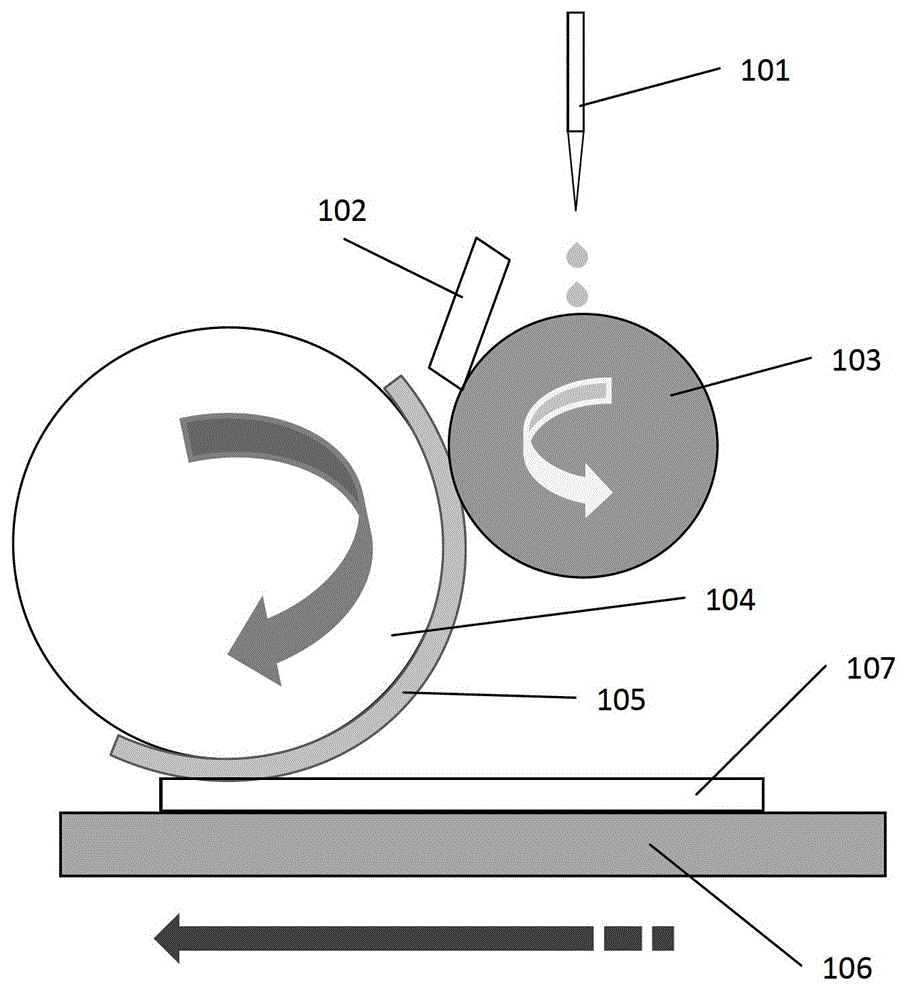

[0027] refer to figure 1 , is a schematic diagram of the principle of the PI film letterpress printing process. The process specifically includes: the dispenser Dispenser 101 spits out the PI liquid and drops it onto the surface of the Anilox roller 103 , while the scraper Blade 102 smoothes the PI liquid on the Anilox roller 103 . The Anilox roller 103 keeps rotating counterclockwise. At the same time, the printing roller Print Roll 104 rotates clockwise, and the printing roller 104 drives the printing relief 105 mounted on it to rotate clockwise. Through the contact and extrusion of the printing relief 105 and the Anilox roller 103 The PI liquid is transferred to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com