Method and clamp for moulding surface positioning clamping of finish forge blade

A technology for positioning and clamping and blades, applied in positioning devices, clamping, manufacturing tools, etc., can solve problems such as blade deformation or damage, and achieve the effects of reduced processing time, good fluidity, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

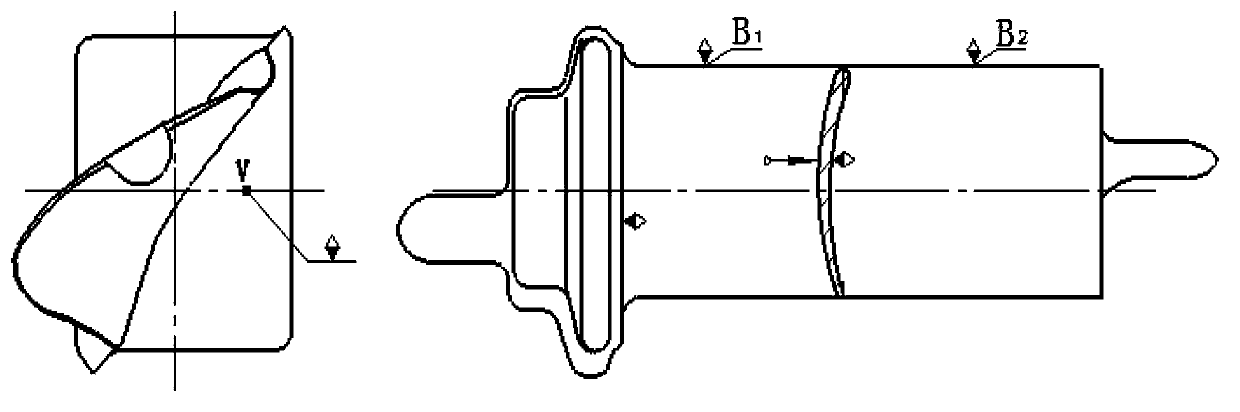

[0045] This embodiment is a method for locating and clamping precision forging blade profiles, and the specific process is:

[0046] Step 1, pretreatment of the glued surface. On the blade pot profile positioning block and the blade back profile clamping block of the fixture, a profile that is offset 2 to 2.5mm outward along the normal direction of the theoretical profile thickness is processed, and the profile surface to be glued Pull hair.

[0047] Step 2, apply glue. Apply TS355 high-precision positioning glue on the profile surface of the blade pot profile positioning block and the blade back profile clamping block of the fixture, and cure it at room temperature for 24 hours. The coating thickness of the high-precision positioning glue is 3.5-4.5 mm. After the high-precision positioning glue is bonded and solidified with the positioning block of the blade basin profile and the clamping block of the blade back profile, the theoretical blade shape of the blade is processe...

Embodiment 2

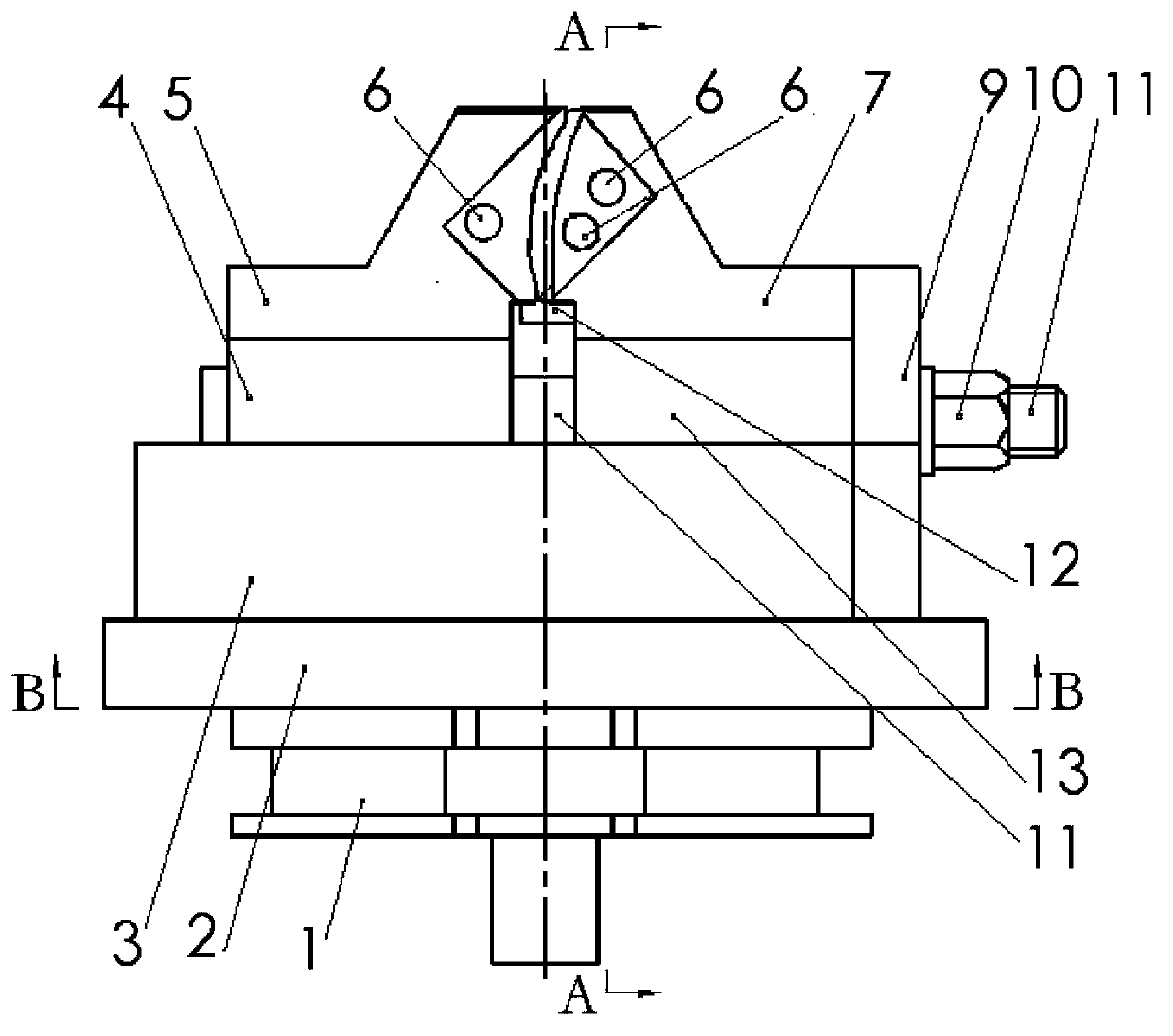

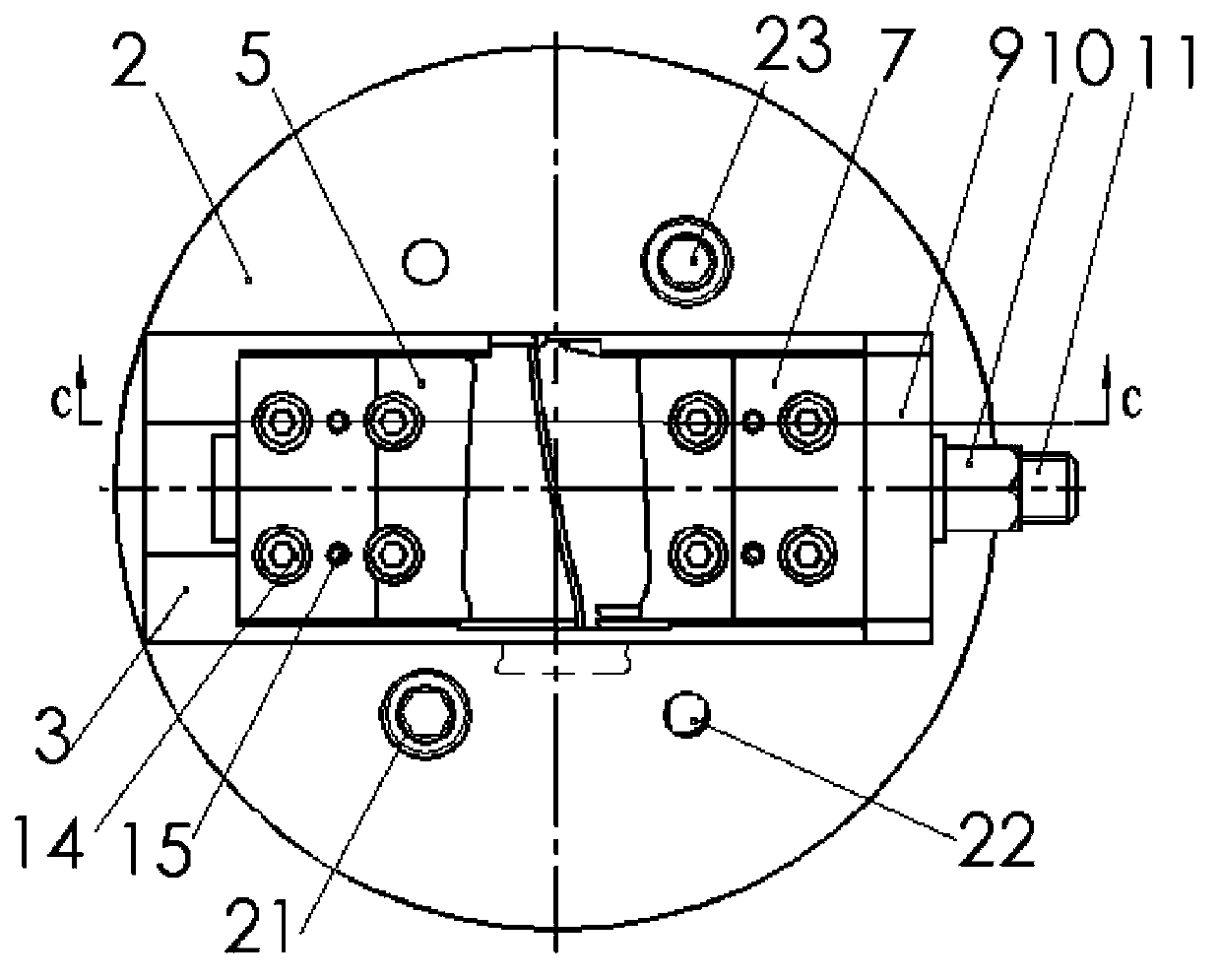

[0052] This embodiment is a fixture for positioning and clamping the surface of precision forging blades. The clamp adopts a vise structure, including a tray 1, a bottom plate 2, a guide rail 3, a clamping guide block 4, a blade back profile clamping block 5, an edge plate positioning pin 6, a leaf pot profile positioning block 7, and a positioning Pin hole 8, baffle plate 9, clamping nut 10, tension rod 11, air intake side positioning pin 12, limit block 13, cylindrical pin 15, limit pin 16, guide plate 17, spring 18 and compression screw 19 .

[0053] like image 3 As shown, the pallet 1 is the connecting piece between the present embodiment and the machine tool. A bottom plate 2 is attached to the upper surface of the tray 1 . The guide rail 3 is horizontally installed at the center of the upper surface of the base plate 2, and the centerline of the length direction of the guide rail 3 is perpendicular to the main shaft of the machine tool; the guide rail groove of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com