Excavator guide assembly guiding aluminum wheel mould and die casting process

A technology of guide components and excavators, applied in the field of die-casting molds, can solve the problems of low production efficiency and high cost, and achieve the effects of reduced production costs, improved production efficiency, and small sand holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Example: This example is a die-casting mold and production process parameters for the aluminum wheel of the guide assembly of an excavator. The shape of the casting is a disc, with a diameter of 350 mm and a thickness of 50 mm. This casting was originally made by casting or hard mold casting.

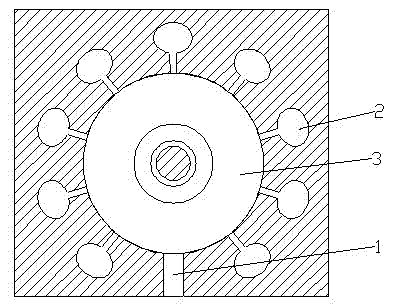

[0016] Such as figure 1 , The thickness of the gap gate of the design mold is 20mm, the cross-sectional area of the slag discharge bag is 40mm×100mm, and a total of 9 are distributed outside the circumference. Use 1000T die casting machine for die casting, die casting machine accumulator pressure 11Mpa, casting cycle 4min, holding temperature 650~680℃, injection speed 0.3m / s, aluminum liquid used is ZL107, ADC10 or ADC12, total weight 3310 g.

[0017] Casting properties after molding: density 2.5~2.9g / cm 2 , The casting hardness is HB100, the tensile strength is greater than 271Mpa, and the elongation is greater than 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com