Manual feeding device used in full-automatic numerical control hydraulic pipe bender

A fully automatic, pipe bending machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of difficult feeding, lower production efficiency, time-consuming, etc., to reduce the burden of feeding, improve work efficiency, The effect of job safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The manual feeding device in the fully automatic numerically controlled hydraulic pipe bender according to the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

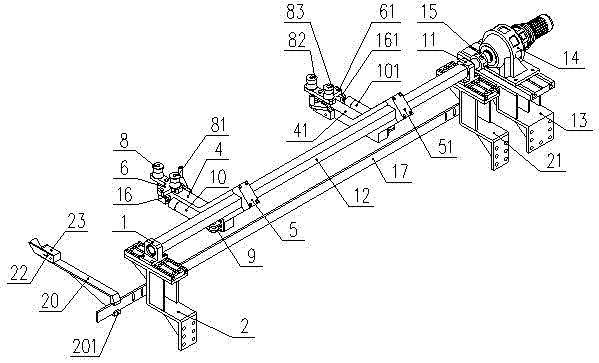

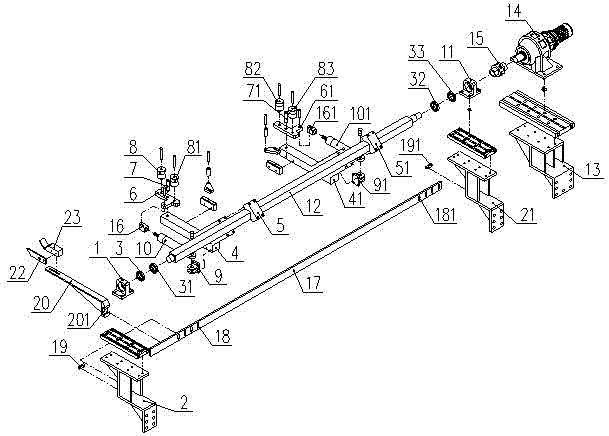

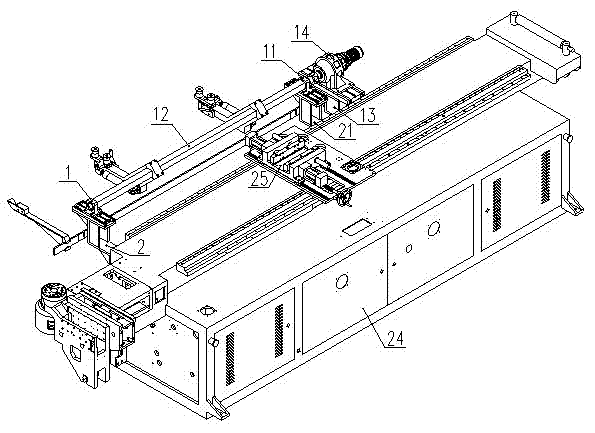

[0017] see figure 1 , figure 2 , image 3 As shown, the manual feeding device in the fully automatic numerically controlled hydraulic pipe bender of the present invention includes: a motor support 13 fixed on the side of the large stand 24 and a pair of bearing supports, namely bearing supports 2, The bearing seat support 21, the motor support 13 is fixedly provided with a geared motor 14; the bearing seat support 2 is provided with a bearing seat 1 - in this embodiment, a bearing is provided in the inner hole of the bearing seat 1 3. Bearing 31, bearing seat 11 is provided on the bearing seat support 21 - in this embodiment, bearing 32 and bearing 33 are arranged in the inner hole of bearing seat 11, and bearing 3, bearing 31, bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com