Fermentation and coating of lysine and cellulose

A technology of cellulase and lysine, which is applied in the field of fermentation to prepare L-lysine products, and can solve the problems of weakened enzyme activity, trouble, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

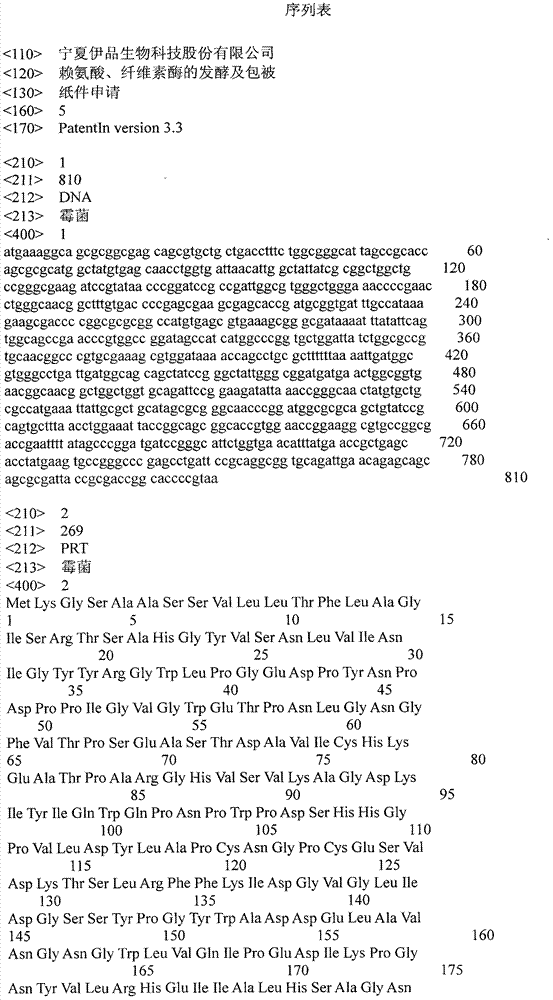

[0056] Embodiment 1 The preparation of the expression construct of the heat-resistant and dehydration-resistant cellulase gene

[0057] According to the strain we found, we commissioned the Institute of Microbiology, Chinese Academy of Sciences to conduct sequence analysis, and found a new cellulase gene, its nucleotide sequence is shown in SEQ ID No: 1 in the sequence table, and the encoded cellulase gene The amino acid sequence is shown in SEQ ID No:2. Then, according to the "Molecular Cloning Experiment Guide" and the operating guide of the commercial reagents used to construct the secretory expressed yeast, in short, the gene encoding the cellulase is used as a forward primer as shown in SEQ ID No: 3 of the sequence listing Shown (introduced EcoR I endonuclease site), reverse primer as shown in SEQ ID No: 4 of the sequence table (introduced Not I endonuclease site) with EcoR I and Not I double digestion after amplification , and ligated with the pPIC3.5 plasmid digested b...

Embodiment 2

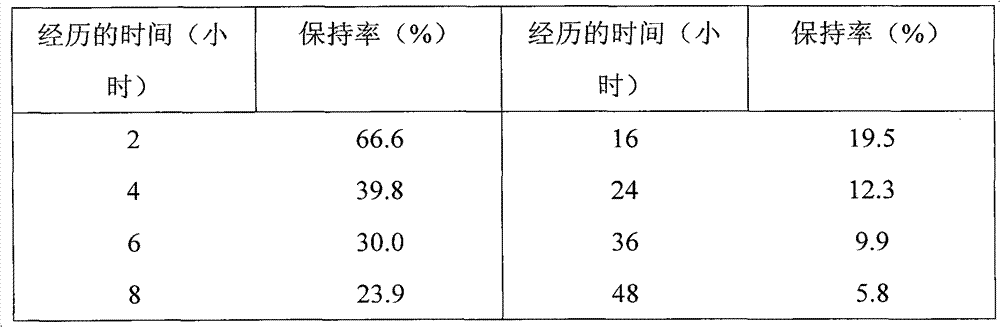

[0058] Example 2 Fermentation preparation and activity determination of heat-resistant and dehydration-resistant cellulase

[0059] Inoculate the positive yeast transformant obtained in Example 1 into 50ml BMGY liquid medium (100mM potassium phosphate buffer (pH6.0), containing 1% yeast extract, 2% peptone, 1.34% yeast nitrogenous base, biological Prime 4*10 -5 %, glucose 2%, glycerol 1%), cultured at 30°C, 200rpm until OD600 reached 5.0.

[0060] Transfer the above culture to 1L BMGY liquid medium, cultivate at 30°C, 200rpm for 24 hours, add 5ml of methanol, and then continue to cultivate at 30°C, 200rpm for 6 days, during which 5ml of methanol was added every 24 hours, and the solution was controlled by ventilation. Oxygen (DO) is greater than 20%, and the pH is controlled to be 6.0 (adjusted with ammonia water). After the cultivation is completed, filter with a 0.22 μm filter membrane and retain the supernatant, which is detected by SDS-PAGE to be rich in the protein corr...

Embodiment 3

[0064] The fermentative production of embodiment 3L-lysine

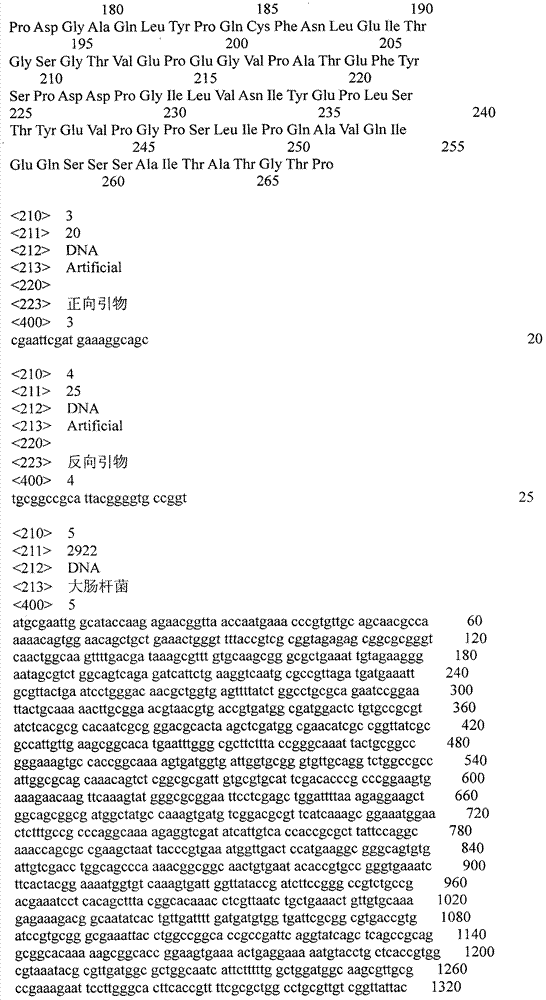

[0065] As described in Chinese patent 201110065683.5, the pyridine nucleotide transhydrogenase variant gene (its nucleotide sequence is shown in SEQ ID No: 5 of the sequence listing) was cloned into the Escherichia coli-coryneform bacteria shuttle plasmid pMS2 ( Can be purchased from the American Type Microorganisms Collection (ATCC, product number ATCC 67189) between the EcoR I and Xba I endonuclease sites, electrotransformed into L-lysine fermented coryneform bacteria engineering bacteria (available from the American Type Microorganisms Collection) Microorganisms Collection Center (ATCC), product number ATCC 31269), obtained coryneform bacteria engineering bacteria.

[0066] Insert this coryneform bacterium engineering bacterium with 0.5% inoculation amount into 20 cubic meters of fermenters (the culture medium formula is: 600 kilograms of glucose, 200 kilograms of sugarcane molasses, 520 kilograms of corn steep li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com