Round thermoelectric generator of automobile exhaust semiconductor

A technology for thermoelectric generators and automobile exhaust, which is applied in the direction of generators/motors, electrical components, etc., to achieve the effects of convenient installation, economical application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

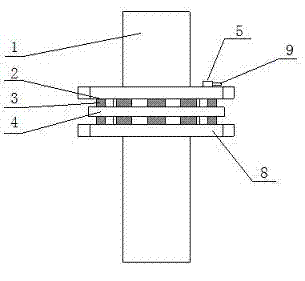

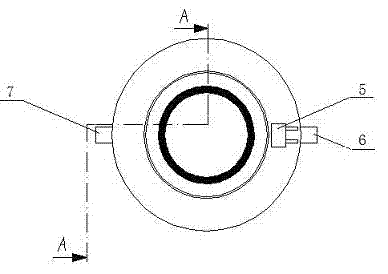

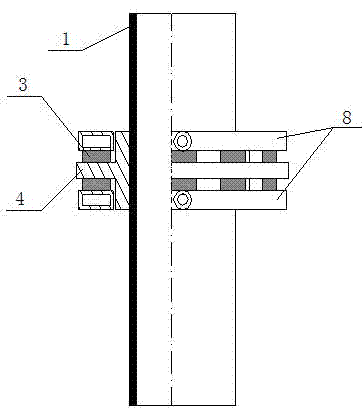

[0023] Embodiment: the heat collector 4 of the circular automobile exhaust semiconductor thermoelectric power generation device is designed as a cylindrical shape with a raised outer edge, made of an aluminum alloy with high thermal conductivity, and the inner hole of the heat collector 4 with a raised outer edge It is close to the automobile exhaust pipe 1, and can absorb the heat of the heat source stably.

[0024] The ceramic plate on the cold and hot surface of the thermoelectric module 3 of the present invention is pasted with high thermal conductivity graphite paper 2, the graphite paper 2 on the hot surface is closely attached to the heat collector 4 with protrusions, and the hot surface of the thermoelectric module does not contact the exhaust pipe horizontally to reduce exhaust Instability caused by thermal expansion and contraction of the trachea and the impact of burning out the thermoelectric module due to instantaneous high temperature, the cold surface graphite pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com