Method for quantitatively evaluating orientation degree of short fiber reinforced composite fibers

A composite material fiber and short fiber reinforced technology, which is applied in the direction of material analysis, material analysis by optical means, material analysis by measuring secondary emissions, etc., can solve the problems of cumbersome processing and complex calculation models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

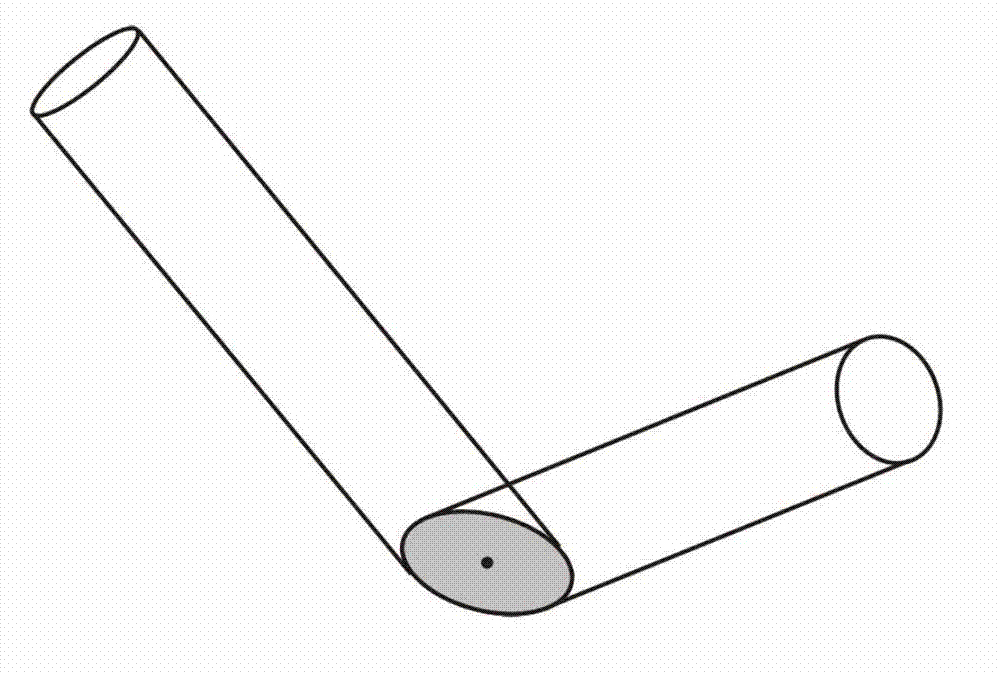

[0034] Take the hot extrusion forming of chopped carbon fiber reinforced magnesium matrix composites as an example. Cylindrical chopped carbon fiber reinforced magnesium matrix composites Figure 4 location shown in (attached Figure 4 As shown in 4 in (a), above the magnesium-based composite material is a magnesium alloy, and the magnesium-based composite material and magnesium alloy are heated to 420°C for extrusion, so that the composite material fills the mold cavity (attached Figure 4 (b)). After cooling, take out the composite parts, as attached Figure 5 shown. Before forming chopped carbon fiber reinforced magnesium matrix composites, the internal fiber orientations are approximately randomly distributed, but after the composites are formed, the internal fiber orientation state will change.

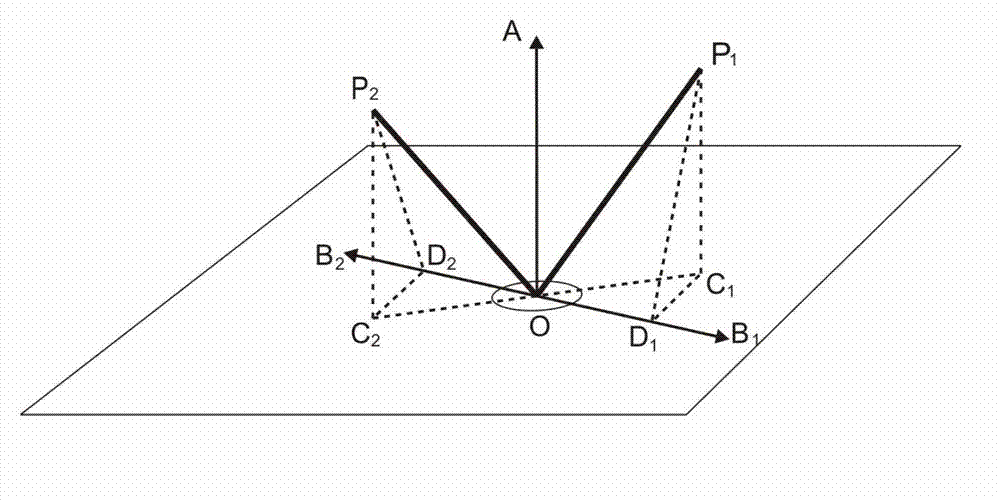

[0035] The length-to-diameter ratio of short fibers insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com