Analytical equipment for detecting particle size and/or particle form

A technology for analyzing equipment and particle shape, which is used in particle size analysis, particle and sedimentation analysis, and material analysis, etc., to achieve the effect of simple equipment operation, high detection efficiency, and automatic counting and display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

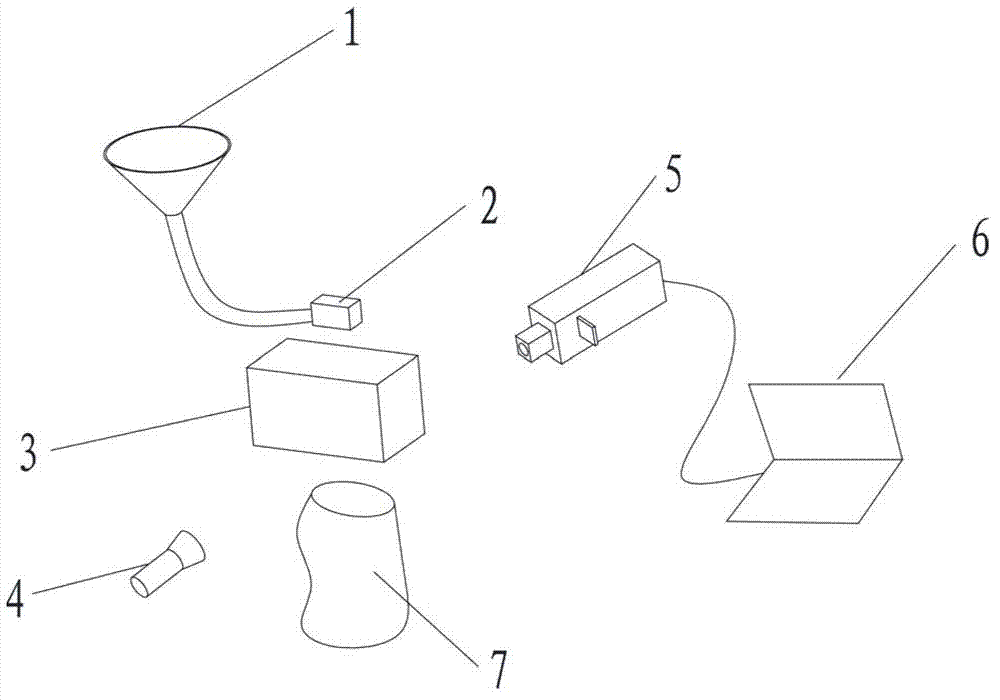

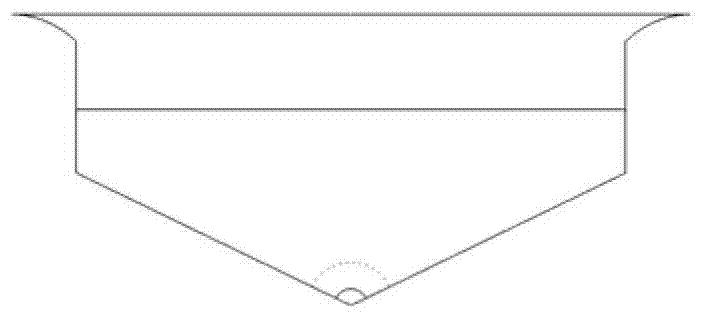

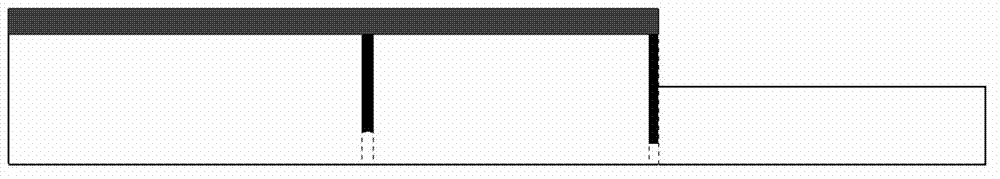

[0025] figure 1 It is an exemplary structural diagram of the present invention. According to this embodiment, the analytical equipment for detecting powder and particle size and particle shape provided by the present invention includes: sampling device 1, counting device 2, dispersion system 3, and light source 4 , imaging system 5 and image processing system 6.

[0026] Among them, the sampling device 1 is used to load the test sample and transport it to the dispersion area; the counting device 2 is located at the end of the sampling device 1, just above the dispersion system 3, and is used to record the number of samples measured; the dispersion system 3 is located in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com