Micro water density measuring device

A micro-water density and measuring device technology, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of on-site staff injury, corrosion of metal objects and insulating parts, shortening the service life of high-voltage switches, etc., and achieves simple structure and high The effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

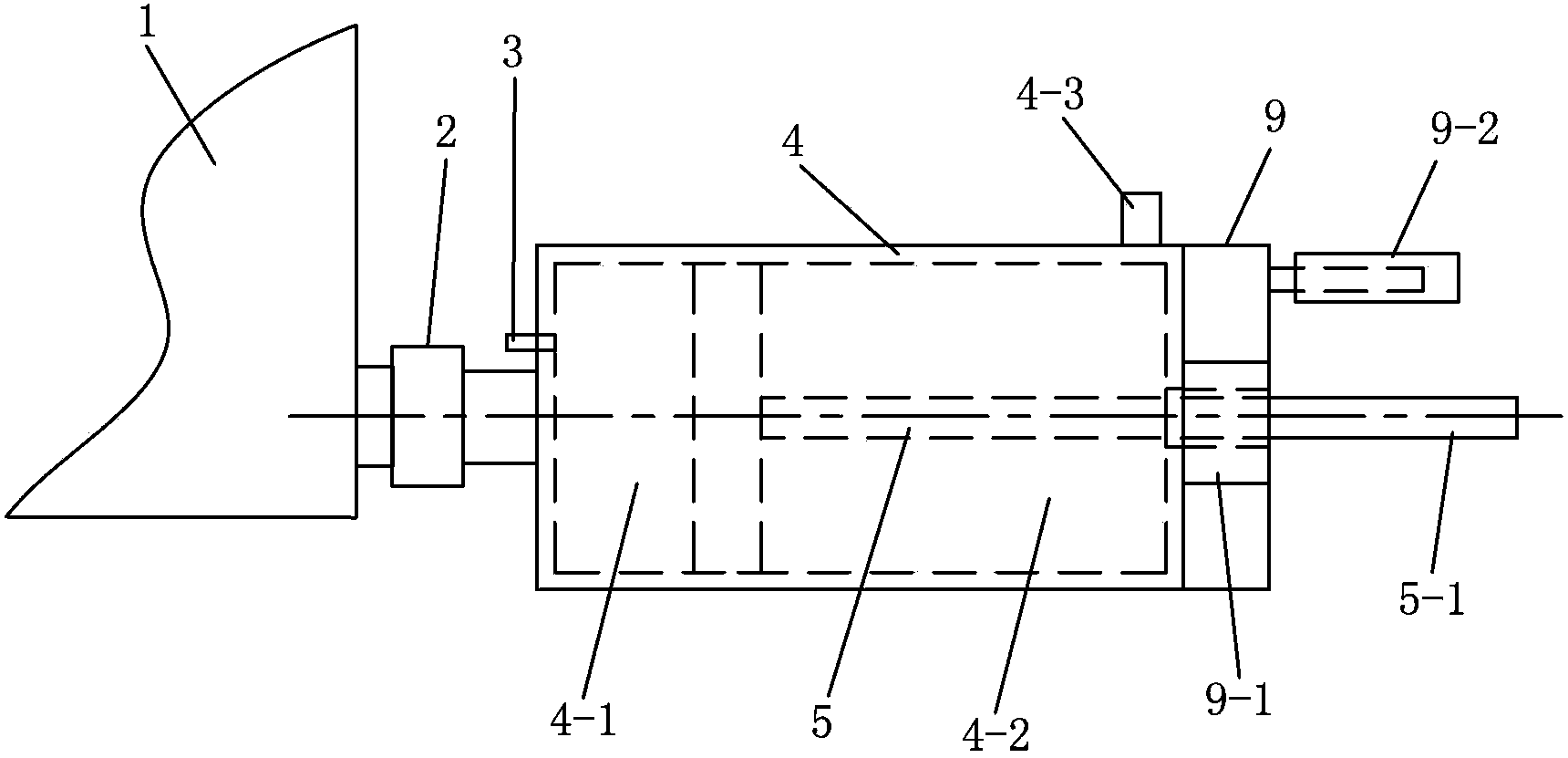

[0033] Such as Figure 4-5 , on the basis of Embodiment 1, the water density measuring device of the present embodiment has the following modifications:

[0034] The gas exchange chamber 4 includes an air bag 4-4 connected to the joint 2, the air bag 4-4 is integrally arranged in a high-pressure gas tank 11, and the high-pressure gas tank 11 is connected to an air pump through the interface 11-1. The pipeline between the joint 2 and the inlet of the air bag 4-4 is provided with a sensor 3 for detecting the density of gas micro-water in the pipeline.

[0035] Before starting work, after taking out the integral body composed of the joint 2 and the high-pressure gas tank 11 from the drying equipment or desiccant, quickly connect the joint 2 to the exhaust port of the device under test 1, and the air bag 4-4 at this time The volume of is zero, and the air pressure in the high-pressure gas tank 11 is less than the air pressure in the air bag 4-4, as Figure 4 .

[0036] ...

Embodiment 3

[0038] Such as Figure 4-5 , on the basis of Embodiment 1, the water density measuring device of the present embodiment has the following modifications:

[0039] The gas exchange chamber 4 includes an air bag 4-4 connected to the joint 2 through an air pump 10, and the pipeline between the joint 2 and the air pump 10 is provided with a sensor for detecting the gas micro-water density in the pipeline 3.

[0040] Before starting work, after taking out the integral body composed of the joint 2 and the high-pressure gas tank 11 from the drying equipment or desiccant, quickly connect the joint 2 to the exhaust port of the device under test 1, and the air bag 4-4 at this time volume is zero.

[0041] Open the exhaust port of the device under test 1, and when the gas of the device under test 1 is sent into the air bag 4-4, the volume of the air bag 4-4 expands, as Image 6 After the micro-water density measurement is completed, the air pump 10 is turned on, and all the gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com