Nano activating agent

An activator and nanotechnology, applied in the field of pesticides, can solve the problems of inability to fully and effectively control the development of plant diseases, high costs, plant diseases, etc., and achieve the effect of promoting the self-repair function of plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

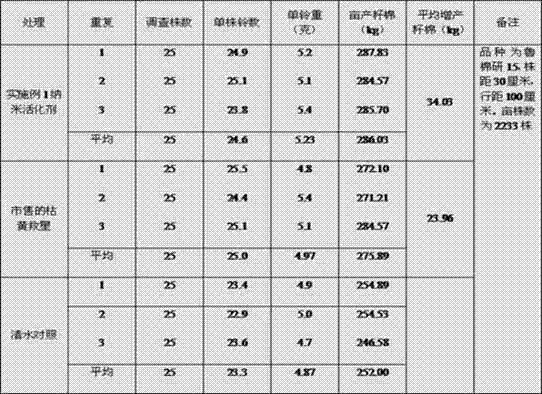

Embodiment 1

[0017] The preparation of embodiment 1 nano-activator

[0018] 40 parts of Junduqing, 40 parts of amino acid, 0.1 part of fulvic acid salt, 0.1 part of cytokinin, 0.005 part of naphthalene acetic acid, 0.5 part of water at 30°C, 0.1 part of potassium fulvic acid, 1 part of rare earth, 0.2 part of ferrous sulfate 1 part of boron sulfate, 1 part of magnesium sulfate, 1 part of manganese sulfate, 1 part of zinc sulfate, 0.005 part of molybdenum sulfate, 1 part of potassium dihydrogen phosphate, 1 part of urea, and 0.007 part of gibberellin.

[0019] The nano-activator includes the following production process: mix 40 parts of Junduqing with 5% water and 40 parts of amino acid; melt 0.1 part of potassium fulvic acid and 0.1 part of fulvic acid salt with 0.5 part of 30 ° warm water Add 0.2 part of ferrous sulfate, 1 part of boron sulfate, 1 part of magnesium sulfate, 1 part of manganese sulfate, 1 part of zinc sulfate, 0.005 part of molybdenum sulfate, 1 part of potassium dihydroge...

Embodiment 2

[0020] The preparation of embodiment 2 nano-activator

[0021] 45 parts of Junduqing, 45 parts of amino acid, 0.2 part of fulvic acid salt, 0.3 part of cytokinin, 0.01 part of naphthalene acetic acid, 0.8 part of water at 30°C, 0.17 part of potassium fulvic acid, 1 part of rare earth, 0.5 part of ferrous sulfate 1 part of boron sulfate, 1 part of magnesium sulfate, 1 part of manganese sulfate, 1 part of zinc sulfate, 0.01 part of molybdenum sulfate, 1 part of potassium dihydrogen phosphate, 2 parts of urea, and 0.01 part of gibberellin.

[0022] The nano-activator includes the following production process: 45 parts of Junduqing are mixed with 5% water and 45 parts of amino acids; 0.8 parts of 30° warm water are used to melt 0.17 parts of potassium fulvic acid and 0.2 parts of fulvic acid salts. Add 0.5 part of ferrous sulfate, 1 part of boron sulfate, 1 part of magnesium sulfate, 1 part of manganese sulfate, 1 part of zinc sulfate, 0.01 part of molybdenum sulfate, 1 part of po...

Embodiment 3

[0023] The preparation of embodiment 3 nano-activator

[0024] 50 parts of Junduqing, 50 parts of amino acid, 0.5 part of fulvic acid salt, 0.5 part of cytokinin, 0.03 part of naphthalene acetic acid, 1 part of water at 30°C, 0.3 part of potassium fulvic acid, 3 parts of rare earth, 0.6 part of ferrous sulfate 3 parts, boron sulfate 3 parts, magnesium sulfate 3 parts, manganese sulfate 3 parts, zinc sulfate 3 parts, molybdenum sulfate 0.03 parts, potassium dihydrogen phosphate 3 parts, urea 5 parts, gibberellin 0.05 parts.

[0025] The nano-activator includes the following production process: mix 50 parts of Junduqing with 5% water and 50 parts of amino acids; melt 0.3 parts of potassium fulvate and 0.5 parts of fulvic acid with 1 part of 30 ° warm water Add 0.6 parts of ferrous sulfate, 3 parts of boron sulfate, 3 parts of magnesium sulfate, 3 parts of manganese sulfate, 3 parts of zinc sulfate, 0.03 parts of molybdenum sulfate, 3 parts of potassium dihydrogen phosphate, 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com