Slip-ring polishing tool

A tooling and slip ring technology, used in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, unsatisfactory roughness requirements, high prices, etc., to reduce vibration and ensure roughness. degree, the effect of ensuring parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

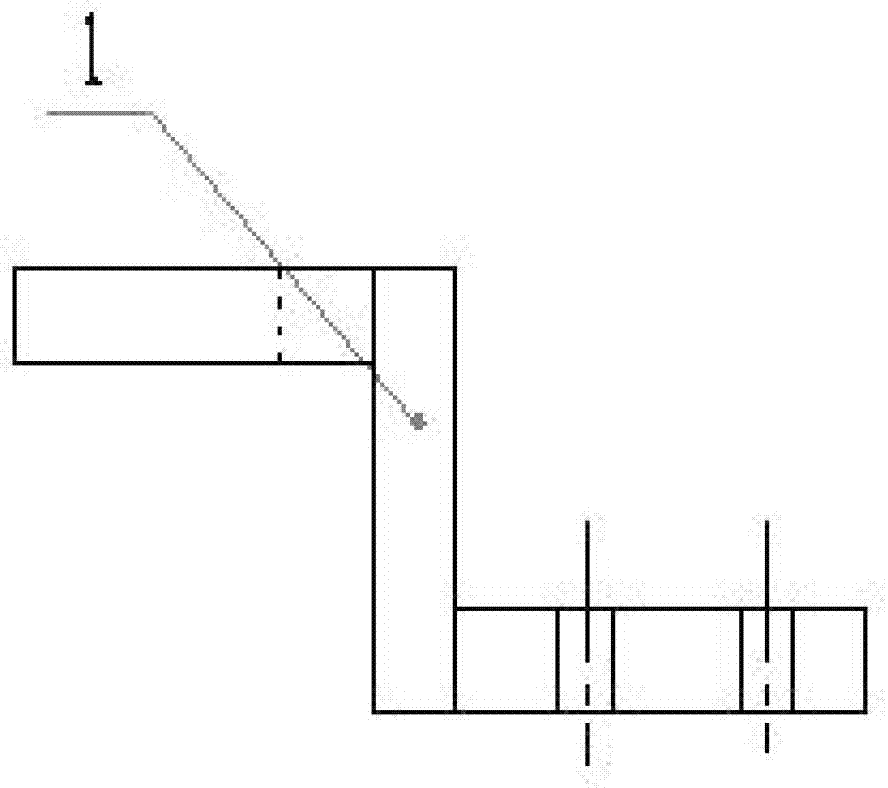

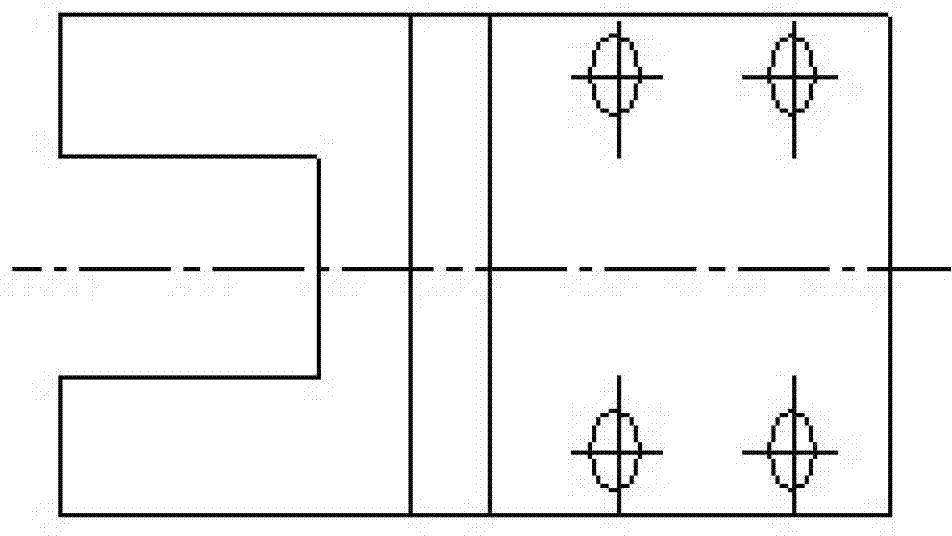

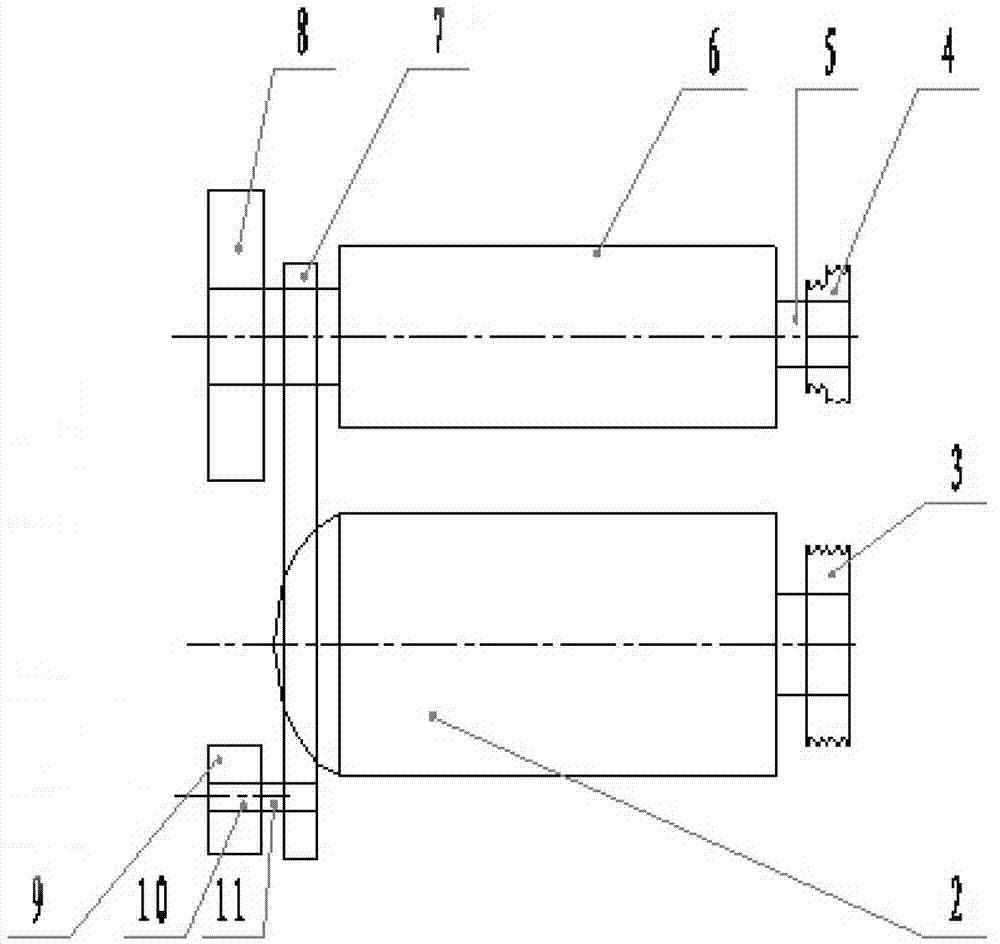

[0012] Such as Figure 1 to Figure 4 Shown: the present invention comprises base 1; The transmission part that is installed on the tool rest of the machine tool that is made up of motor 2, large belt pulley 3, small belt pulley 4, transmission shaft 5, casting bushing 6 and is composed of driving wheel 8, driven wheel 9, The polishing part composed of the pin shaft 11, the shaft sleeve 10 and the fixed arm 7; the cast shaft sleeve 6, the motor 2 and the base 1 are assembled together, the large pulley 3 and the small pulley 4 are connected by a V-belt, and the large pulley 3 is installed on the motor 2 Above, the small pulley 4 is installed on one end of the transmission shaft 5, the other end of the transmission shaft 5 is equipped with a driving wheel 8 and connected to one end of the fixed arm 7, and the driven wheel 9 is fixed and installed on the fixed arm through a pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com