Second-flow based self-adaptive method for controlling thickness of plate of single-stand reversing rolling mill

A self-adaptive control and second flow technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of high-frequency fluctuations in finished products, failure to reflect the thickness of the entrance and exit, and compensation for roll eccentricity, so as to improve accuracy, Improve the effect of thickness control and improve the accuracy of feedforward control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

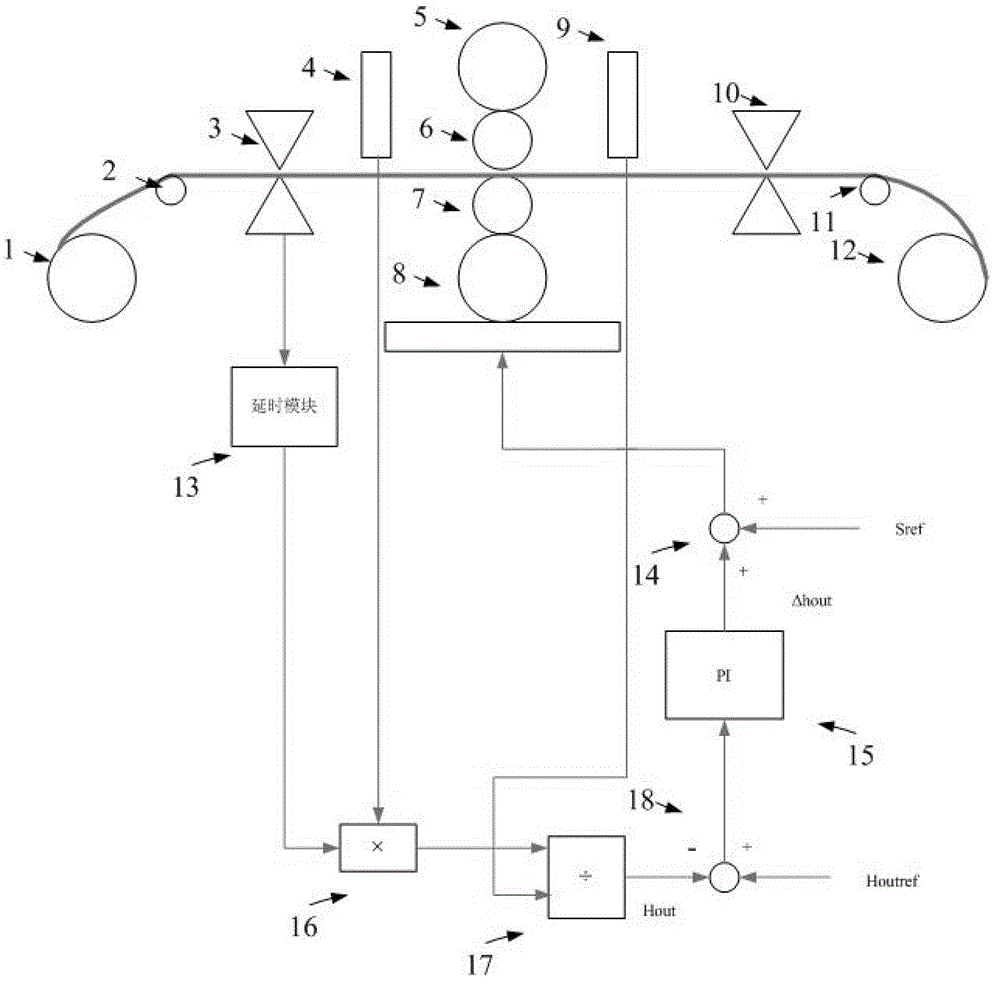

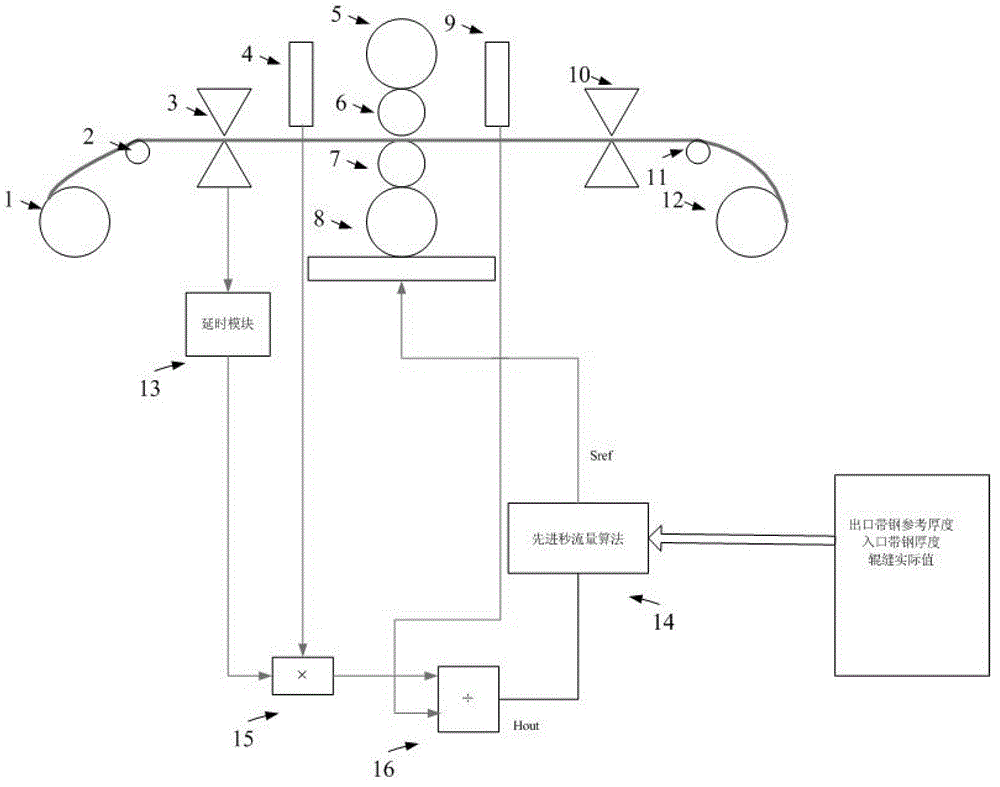

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0018] The hydraulic pressure-roll gap servo system of the present invention is adjusted so that when the roll gap change step value of 20 microns is given near the minimum working pressure of the system, the rise time is τ 1 Second.

[0019] In this paper, for a certain variable B, the expression in the k-th period is B(k), the expression in the k-1 period is B(k-1), and the expression in the k+1 period is B(k+1) . If the variable B is constant, it is directly represented by B in the k period.

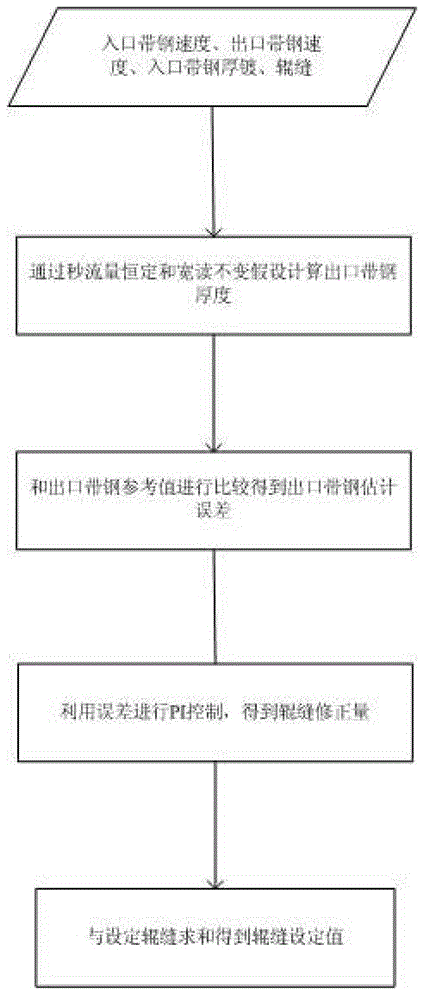

[0020] Further, the method specifically includes the following steps, in the kth execution cycle of the program written according to the method:

[0021] 1. The actual pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com