FexOy-based inorganic nanocomposite and preparation method thereof

A composite material, inorganic nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve the problem of single composite material morphology, few nanocomposite materials, and poor types of composite nanomaterials. and other problems, to achieve the effect of high yield and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

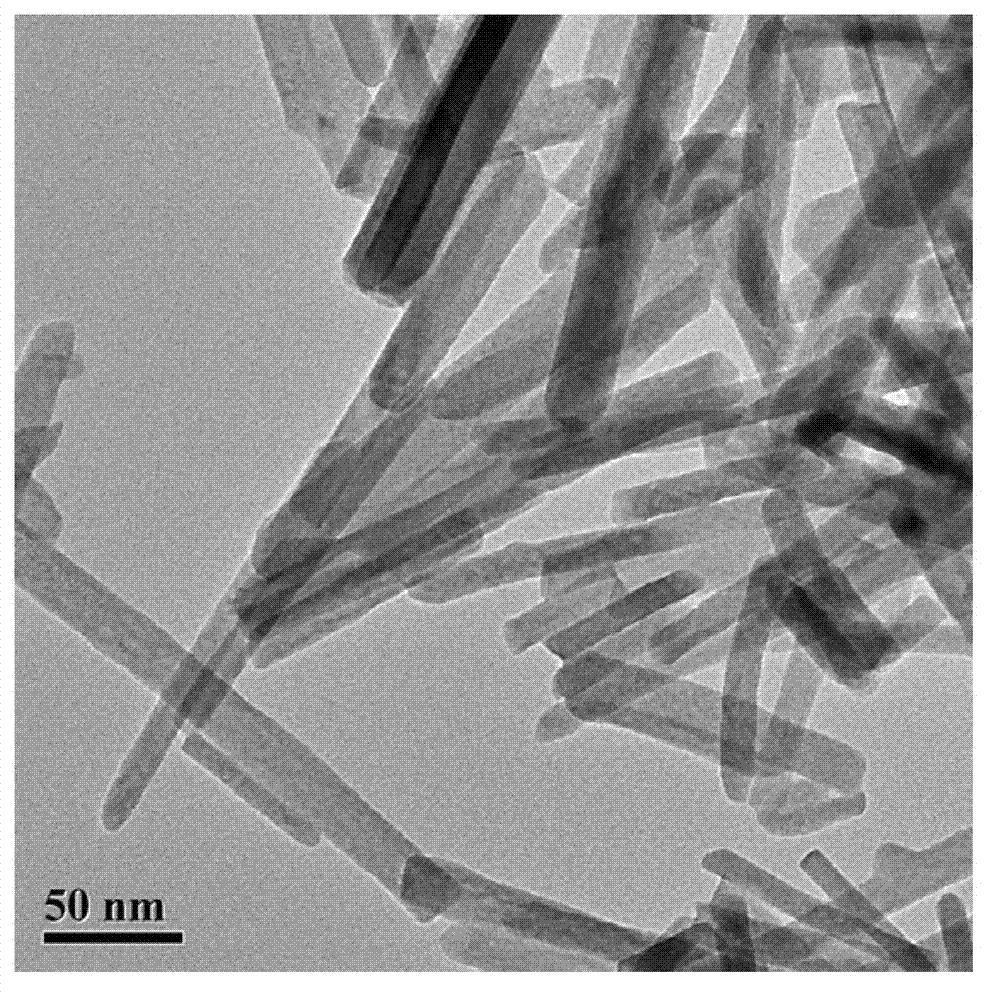

[0027] 1) Add 0.5mmol Ni(NO 3 ) 2 ·6H 2 O was added to 25 ml deionized H 2 O, stirred at room temperature until completely dissolved, 0.08g Fe 3 o 4 Nanoclusters (Fe 3 o 4 For the synthesis of nanoclusters, refer to Angew.Chem.Int.Ed.2005, 44, 2782-2785) Add the obtained clear solution, stir at room temperature for ≥0.5h, then add 10ml0.5mol L dropwise -1 NaOH aqueous solution, stirred at room temperature for ≥15min.

[0028] 2) Transfer the solution obtained in 1) to a 50ml automatic pressure-relieving stainless steel high-pressure digestion tank with a Teflon liner (Binhai County Zhenghong Plastic Factory, model: 50ml), and after 24 hours of treatment at 180 ° C, the natural Cool to room temperature;

[0029] 3) Magnetically separate the solution obtained in 2), and clean the separated solid with a mixed solvent of ethanol and water under ultrasonic conditions, and go through magnetic separation-ultrasonic cleaning cycles for 3-5 times, and finally the cleaned solid ...

Embodiment 2

[0032] Repeat Example 1, the only difference is to process 4h at 180°C to obtain the inorganic nanocomposite material Fe 3 o 4 / NiO.

Embodiment 3

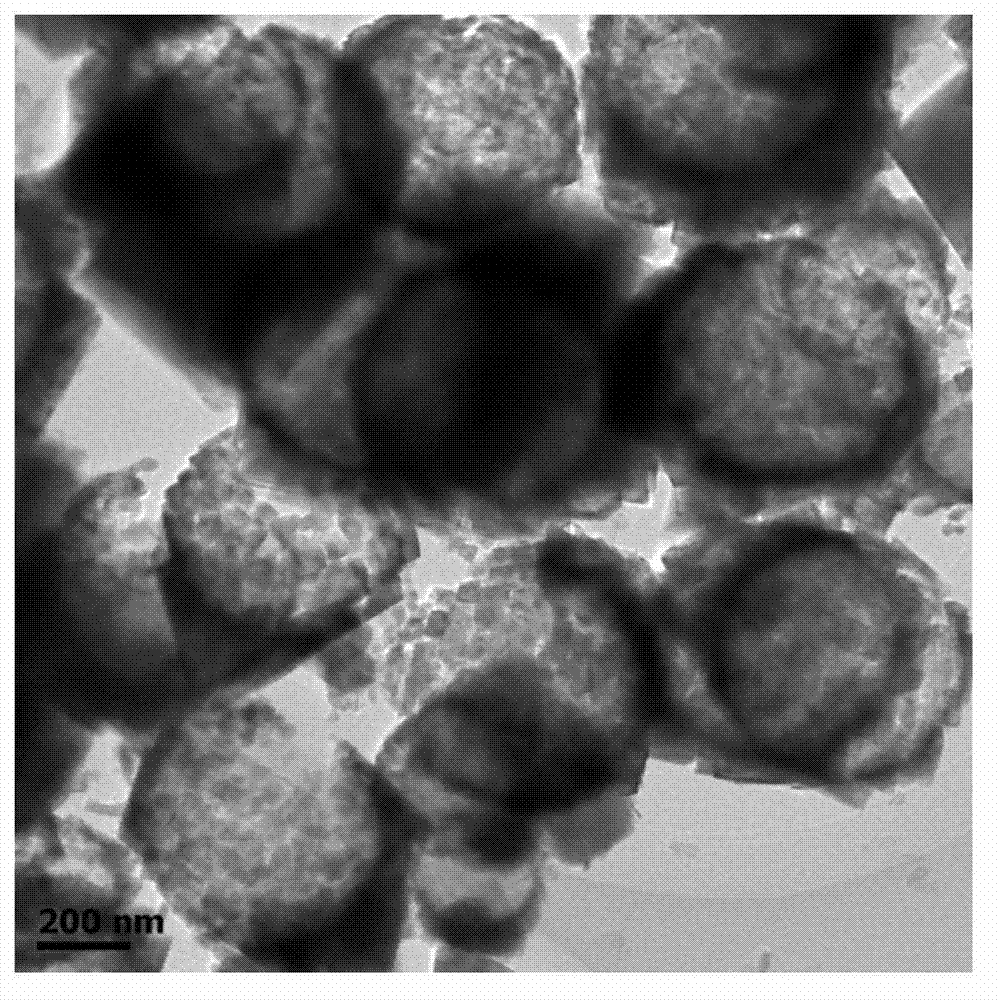

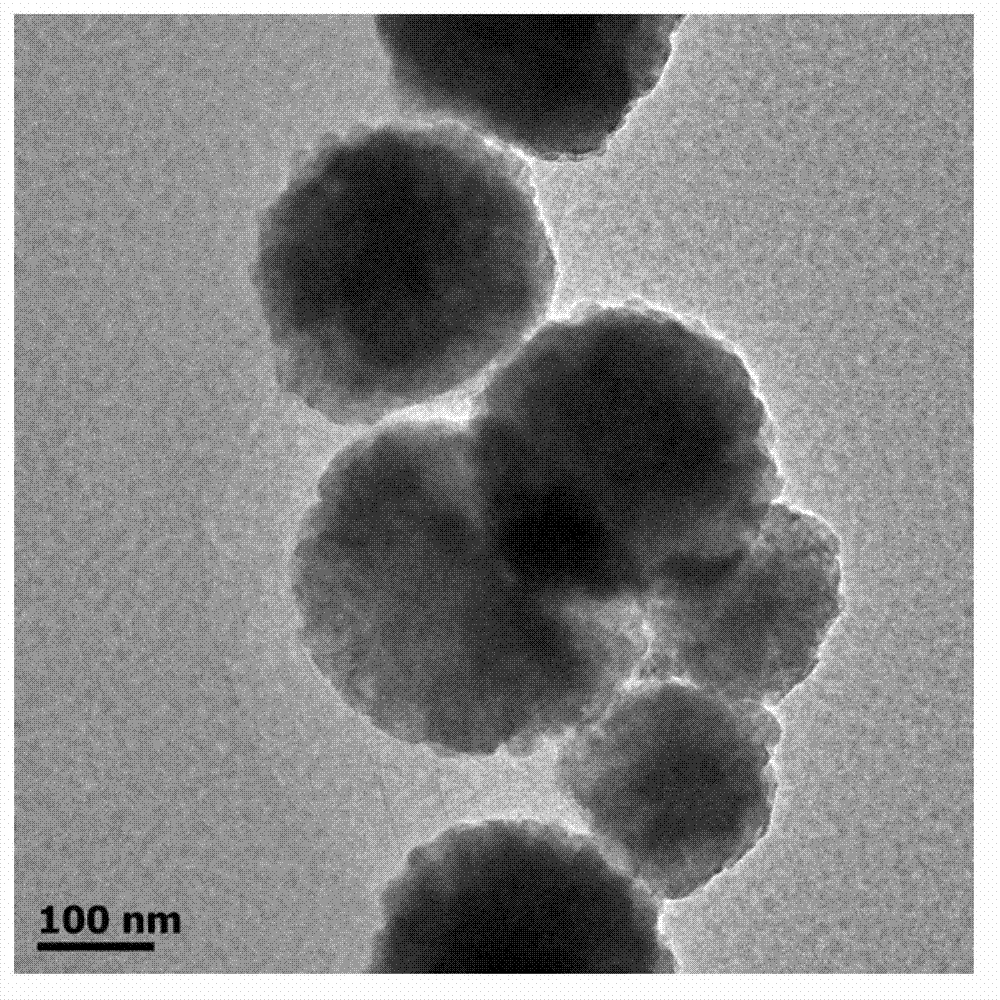

[0034] Repeat embodiment 1, difference is only to use Bi(NO 3 ) 3 ·5H 2 O instead of Ni(NO 3 ) 2 ·6H 2 O, the inorganic nanocomposite Fe 3 o 4 / BiFeO 3 . figure 2 For the inorganic nanocomposite Fe 3 o 4 / BiFeO 3 Electron microscope photographs, via figure 2 It can be seen that the prepared composite nanomaterial has a spherical morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com