Wet-and-dry automatic feeding trough

A wet and dry dual-purpose, feeding trough technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of feeding blockage, unsmooth feeding, low manufacturing cost, etc., to achieve the effect of strengthening the movement, Uniform feeding, not easy to clog the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

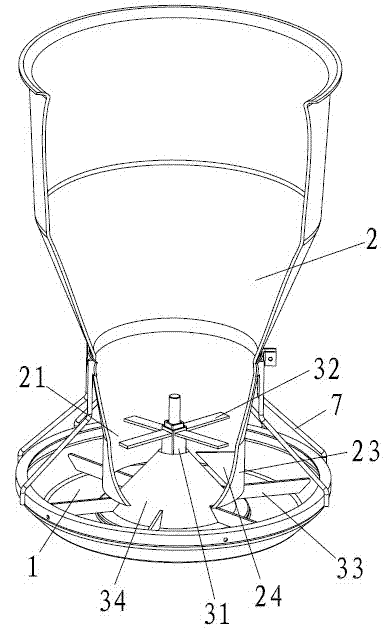

[0035] Embodiment 1: as figure 1 As shown, a dry and wet automatic feeding trough includes a trough 1, a material barrel 2 fixedly connected to the top of the trough 1 through a fixed frame 7, the material barrel 2 has a bottom and a discharge port 21 is formed at its lower part; The barrel 2 extends downwards at the outlet 21 to form a protective ring 23 .

[0036] The middle part of the material trough 1 is rotatably connected with a rotating shaft 31. A rotating arm 32 close to the discharge port 21 and extending outward along the middle part of the discharging port 21 is installed on the rotating shaft 31. The part below the rotating arm 31 is installed on the rotating shaft 31. There is a driving rod 33 for driving the rotating arm 32 to rotate through the rotating shaft 31. Below the discharge port 21, there is a device sleeved outside the rotating shaft 31 and linked with the driving rod 33, which is used to make the feed move along the rotating shaft 31 in the horizont...

Embodiment 2

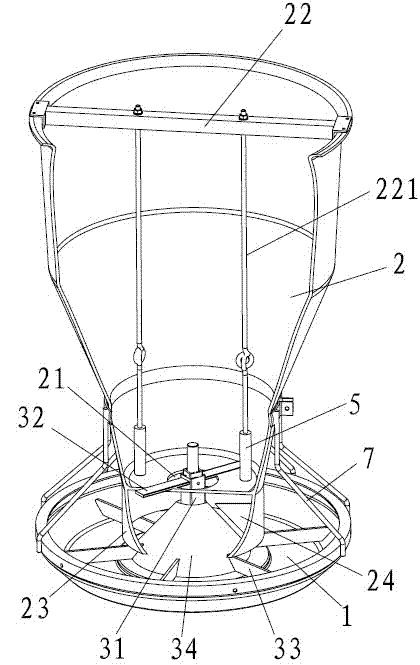

[0039] Embodiment 2: as figure 2 As shown, a wet and dry dual-purpose automatic feeding trough includes a hopper 1 and a material bucket 2 fixedly connected to the top of the material trough 1 through a fixed frame 7; the bottom surface of the material bucket 2 is provided with a discharge port 21; and the material bucket 2 extends downwards at the outlet 21 to form a protective ring 23.

[0040] The middle part of the material trough 1 is rotatably connected with a rotating shaft 31. A rotating arm 32 close to the discharge port 21 and extending outward along the middle part of the discharging port 21 is installed on the rotating shaft 31. The part below the rotating arm 31 is installed on the rotating shaft 31. There is a driving rod 33 for driving the rotating arm 32 to rotate through the rotating shaft 31. Below the discharge port 21, there is a device sleeved outside the rotating shaft 31 and linked with the driving rod 33, which is used to make the feed move along the rot...

Embodiment 3

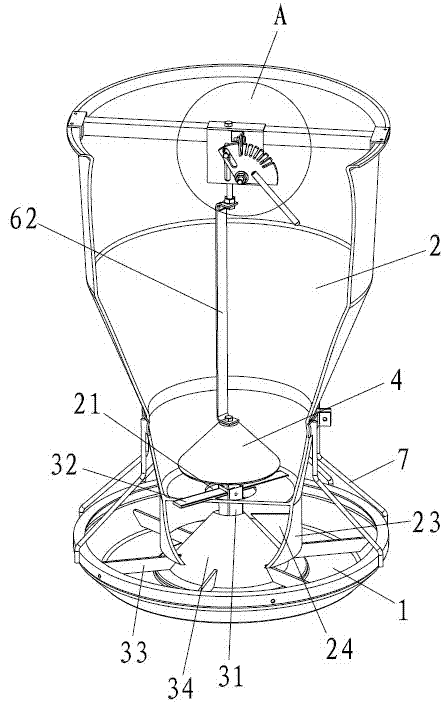

[0047] Embodiment 3: as Figure 3-4 As shown, a wet and dry dual-purpose automatic feeding trough includes a hopper 1 and a material bucket 2 fixedly connected to the top of the material trough 1 through a fixed frame 7; the bottom surface of the material bucket 2 is provided with a discharge port 21, and the material bucket 2 extends downwards at the outlet 21 to form a protective ring 23.

[0048] The middle part of the material trough 1 is rotatably connected with a rotating shaft 31. A rotating arm 32 close to the discharge port 21 and extending outward along the middle part of the discharging port 21 is installed on the rotating shaft 31. The part below the rotating arm 31 is installed on the rotating shaft 31. There is a driving rod 33 for driving the rotating arm 32 to rotate through the rotating shaft 31. Below the discharge port 21, there is a device sleeved outside the rotating shaft 31 and linked with the driving rod 33, which is used to make the feed move along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com