Sweetness enhancers, compositions thereof, and methods for use

A technology of sweetness enhancer and composition, applied in the field of sweetness enhancer, its composition, and use, which can solve the problems of high price of no-calorie or low-calorie sweeteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Pluck and swallow repeatedly

[0087] Suck the first mouth (approximately 2.2 mL) ca. 20 mL of the control composition and swallow. After waiting 15 to 25 seconds, take a second mouth of the control composition and swallow, and then record the sweetness and / or taste of the control composition. After waiting 15 to 25 seconds, repeat these steps with the comparison composition. The difference in sweetness and taste between the control composition and the comparative composition is recorded. For each composition tested, repeat this cycle to confirm the initial result. For consistent comparison, all samples were measured at an average of 23.0°C±1°C between samples and any effect of temperature on the perceived taste or sweetness of the composition was minimized.

[0088] Taste test guide

[0089] To complete the taste test, three sweetener samples were paired with one additive and the taste test as described above was performed. There is a three-minute interval before testing...

Embodiment 2

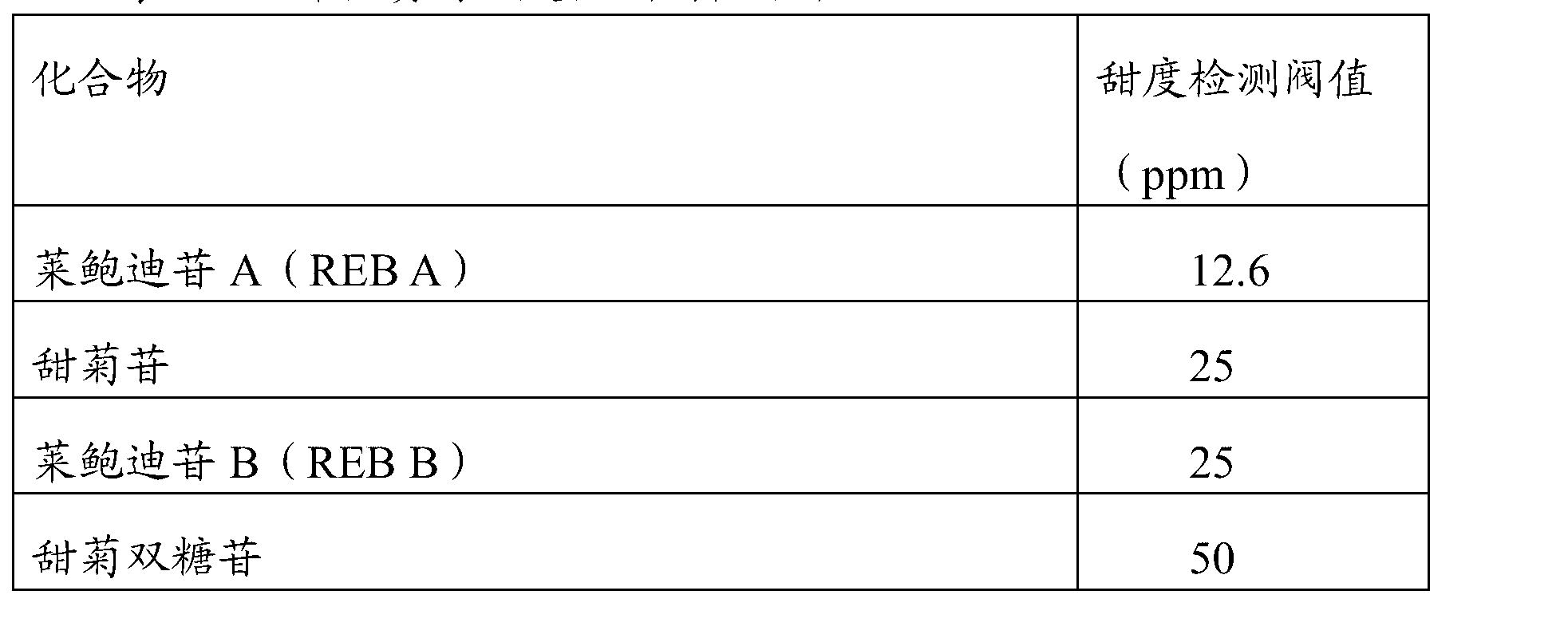

[0107] Steviol Glycosides (Steviol Glycosides) sweetness detection threshold estimation.

[0108] First, 20 mg of steviol glycoside was dissolved in 20 mL of purified water to prepare a 1,000 ppm steviol glycoside solution. A portion of this solution (10 mL) was diluted to 20 mL with water to obtain a 500 ppm solution. In addition, the solutions of 250 ppm, 125 ppm, 62.5 ppm, 31.2 ppm and 15.6 ppm were prepared by serial dilution of 1:1. Those solutions were tasted in ascending order of concentration by experienced subjects by using the puff-and-vomit procedure disclosed herein. The sweetness detection threshold estimated by these subjects was determined to be the lowest concentration at which sweetness was clearly detected.

[0109] Thereafter, 20 mg of rubusoside was dissolved in 200 mL of purified water to prepare a 200 ppm rubusoside solution. A portion of this solution (50 mL) was diluted to 100 mL with water to obtain a 100 ppm solution. Another 1:1 serial dilution to pre...

Embodiment 3

[0115] Purification of crude rubusoside

[0116] About 30 grams of crude rubusoside (63.7%) obtained from Waterstone Tech was dissolved in about 100 mL of 60:40 MeOH and water. The column was packed with 300 grams of reversed-phase material obtained from Phenomenex (Sepra C18; 50um, 65A), which was suspended in 1000 mL of 60:40 MeOH and water. After removing 1000 ml of 60:40 MeOH and water from the filled column, the suspended 30 grams of rubusoside was dissolved in 100 ml of 60:40 MeOH and water on the column. The column was eluted with 2000 mL of 70:30 MeOH and water, and forty fractions (about 50 mL each) were collected. Parts 6-19 show rubusoside. Combine 6-19 parts of ground and concentrate in a rotary evaporator under vacuum to produce 6.6 grams of dry powder. Remove 3 grams of material from it and put it in a round bottom flask and add 15 mL of MeOH. The mixture was refluxed under stirring for 1 hour and cooled to room temperature over 30 minutes. The mixture was stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com