Application and preparation method of copper-aluminum transitional composite connecting bar and multistage composite connecting bar

A manufacturing method, copper-aluminum technology, applied in the direction of cable/conductor manufacturing, connection, connection contact materials, etc., can solve problems such as short circuit, easy breakage, large current transmission overload, etc., reduce transmission resistance, and facilitate secondary shaping and cutting processing , Improve the effect of current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing;

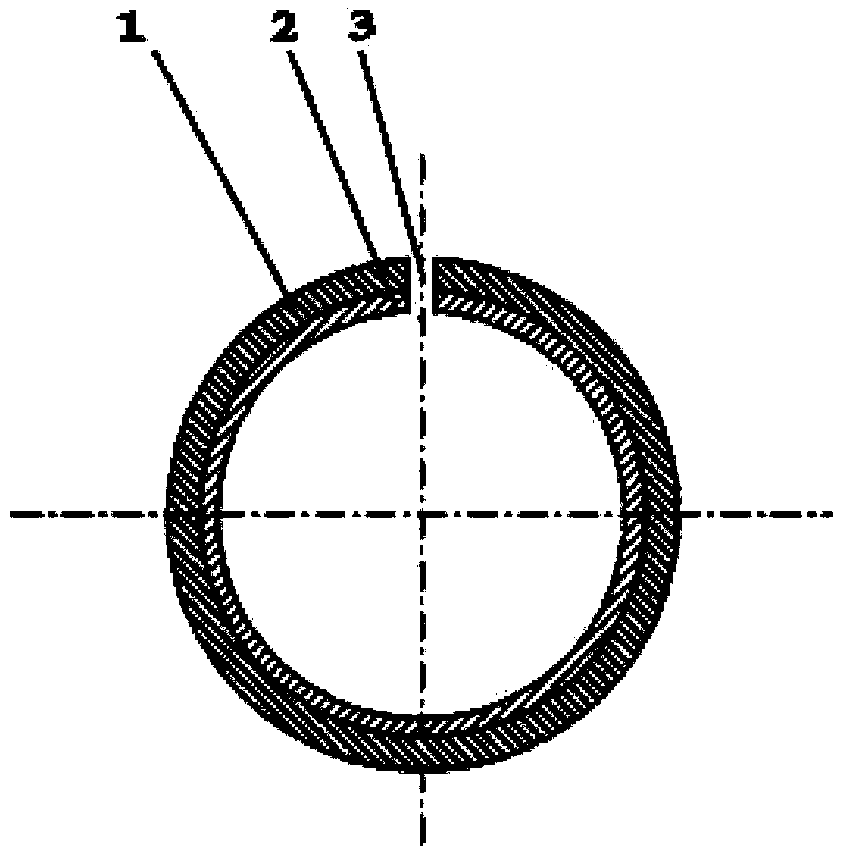

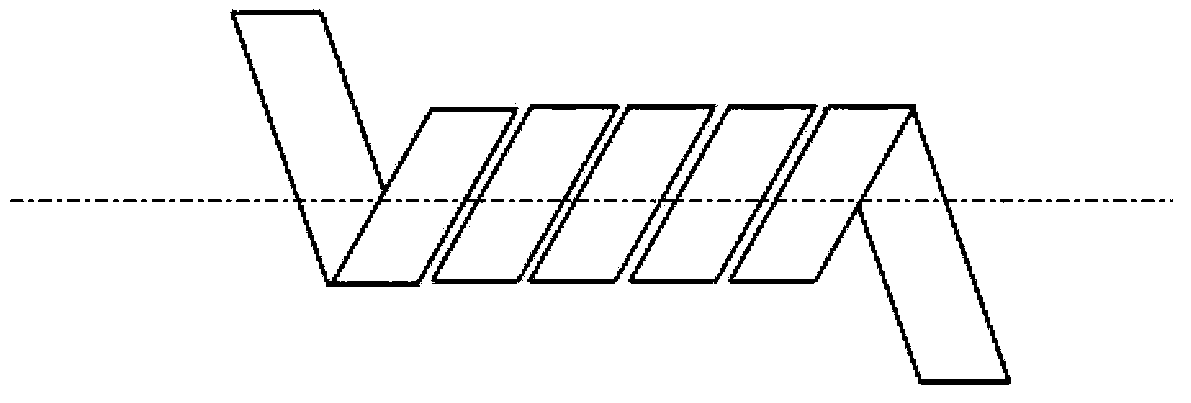

[0030] Depend on Figure 1 to Figure 12 As shown, the technical scheme of the invention relates to the structure, application and manufacturing method of copper-aluminum transition composite connecting strips and longitudinal multi-level connecting strips, such as Figure 1 to Figure 12 shown, where Figure 1 to Figure 3 For the structure of the continuation bar, Figure 4 to Figure 9 is the connection method of the connection bar, Figures 10 to 12 For the production method of the splicing strip.

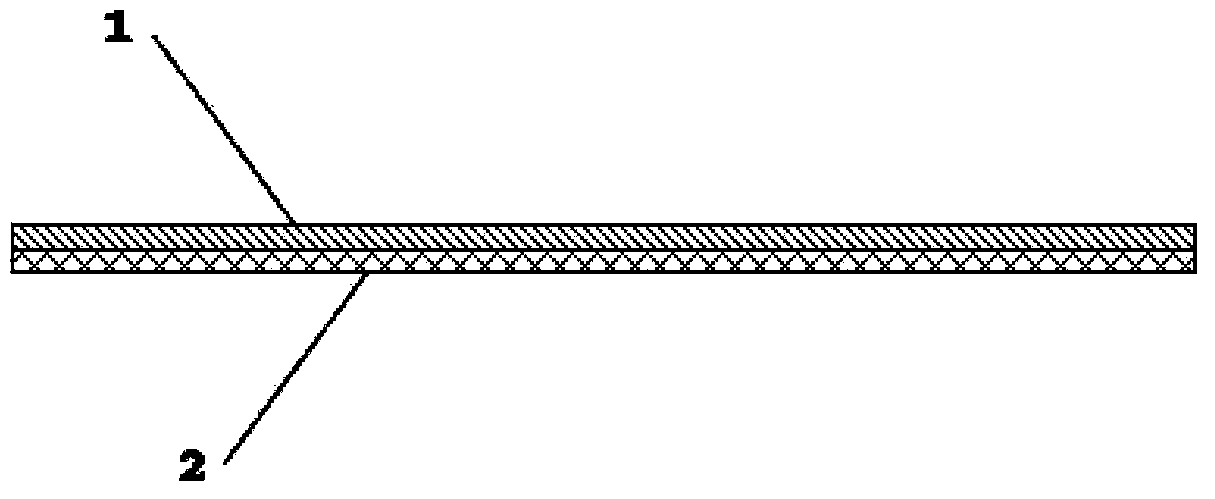

[0031] The basic structure of the copper-aluminum transition strip is as follows: figure 1 , the ultra-thin copper substrate 1 and the ultra-thin aluminum substrate 2 are composited together by detonating cord explosion welding to form an ultra-thin copper-aluminum transition strip, which is characterized by the composite of the above-mentioned ultra-thin copper substrate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com