Bidirectional evolutionary structure topological optimization based disk type flywheel optimized design method

A topology optimization, two-way progressive technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as shape optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

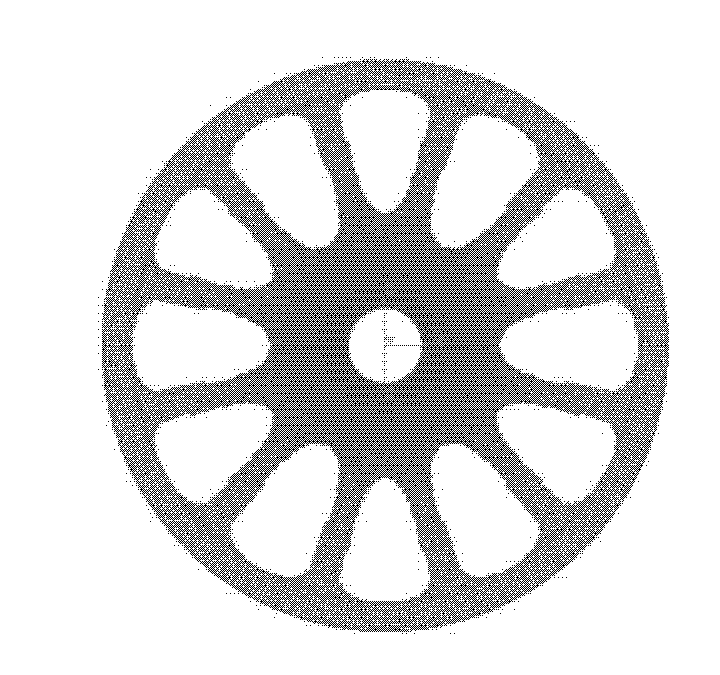

[0043] The high-speed rotating disc flywheel mainly bears the centrifugal load. In practical engineering applications, circular holes of the same size are often evenly distributed along the circumference of the flywheel to reduce the mass of the flywheel. The initial structure of the flywheel of the embodiment of the present invention is as follows: figure 2 As shown (taking the 1 / 6 model of the disc flywheel as an example), the inner and outer ends of the disc flywheel (area 1 and area 3) are non-design areas, which is to ensure that the disc flywheel can be assembled with the shaft at the same time With a certain moment of inertia, only the middle area 2 (except the round hole) is a designable area. The material parameters of the disc flywheel are shown in Table 1, and the size parameters are shown in Table 2. When holes are dug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com