Phase-shifting mask with auxiliary phase areas

A technology of phase shift mask and phase, applied in the field of phase shift mask

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

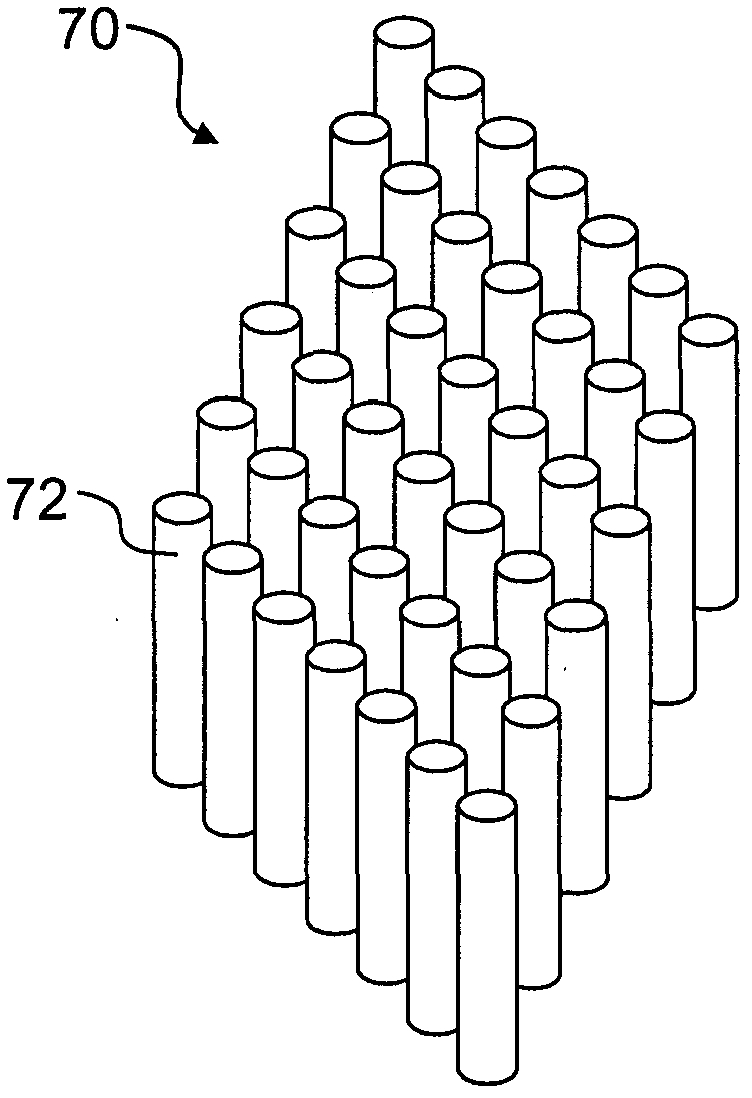

[0050] Reference will now be made in detail to the various embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings. Wherever possible, the same or similar reference numbers and symbols are used throughout the drawings to refer to the same or similar parts. The drawings are not necessarily to scale, and those skilled in the art will recognize that the drawings have been simplified to illustrate key aspects of the disclosure. For example, with respect to the phase shift masks disclosed herein, such masks can contain many thousands of phase regions, and in some figures a limited number of phase regions are shown as illustrations.

[0051] Aspects of the phase shift mask with auxiliary phase regions of the present disclosure are discussed exemplarily in connection with the fabrication of LEDs. Accordingly, information pertaining to LED structure and fabrication by photolithography is set forth below.

[0052] Exemplary LED Structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com