Tungsten oxide nanoflake self-assembly nanosphere and application method and application of tungsten oxide nanoflake self-assembly nanosphere

A self-assembly, tungsten oxide technology, applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology, material resistance, etc., can solve the problems such as the application of nano-tungsten oxide self-assembly structure, which is easy to popularize, easy to operate, high Effects of sensitivity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Accurately weigh 2.6080g of sodium tungstate dihydrate and dissolve it in 30mL of deionized water, place it in a KQ-250B ultrasonic generator for ultrasonic dissolution, then add 1.000g of oxalic acid, and after it is completely dissolved, use a hydrochloric acid solution with a concentration of 3.00mol / L Slowly add it dropwise to the above solution until the pH value is 1.30, continue ultrasonication for 60 minutes, centrifuge and wash the obtained yellow precipitate, and dry it at 60°C for 12 hours to obtain tungsten oxide powder.

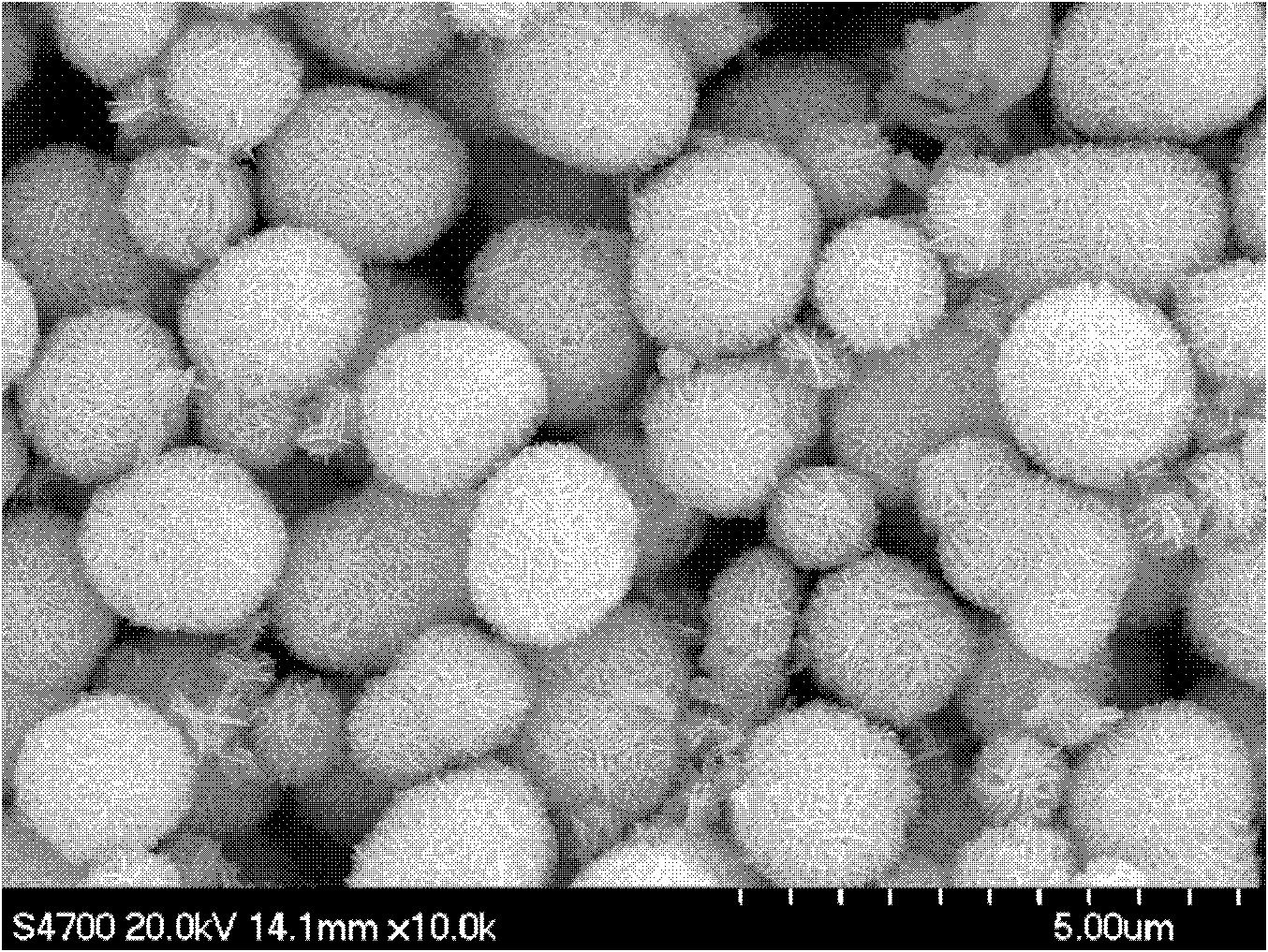

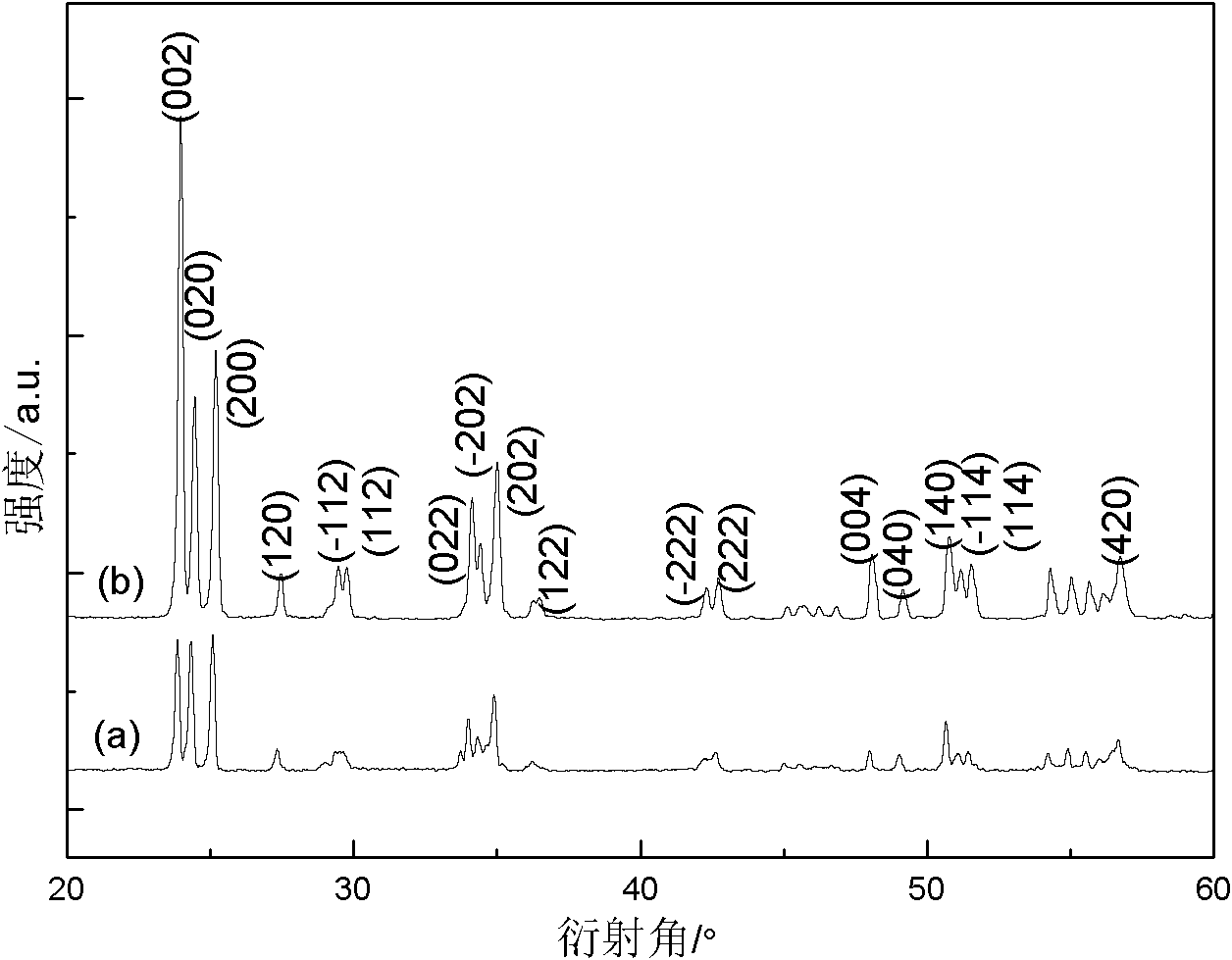

[0024] The scanning electron microscopy results of the figure 1 and figure 2 , the diameter of tungsten oxide microspheres is 1-3 μm, and they are self-assembled from lamellar structural units with a thickness of 10-20 nm; the XRD analysis results of the prepared tungsten oxide powder are shown in image 3 , the obtained product is monoclinic tungsten oxide with high crystallinity.

Embodiment 2

[0026] Accurately weigh 1.3040g of ammonium paratungstate and dissolve it in 20mL of deionized water, place it in a probe ultrasonic generator for ultrasonic dissolution, add 0.7000g of oxalic acid, and after it is completely dissolved, slowly add a hydrochloric acid solution with a concentration of 3.00mol / L to the above solution until The pH value was 1.30. After continuing to sonicate for 120 minutes, the obtained pale yellow precipitate was centrifuged and washed, and dried at 60° C. for 12 hours to obtain tungsten oxide powder.

Embodiment 3

[0028] Accurately weigh 1.3040g of sodium tungstate dihydrate and dissolve it in 20mL of deionized water, place it in a KQ-250B ultrasonic generator for ultrasonic dissolution, add 0.5000g of oxalic acid, and slowly dissolve it with a nitric acid solution with a concentration of 3.00mol / L after it is completely dissolved. Add it dropwise to the above solution until the pH value is 1.52, continue ultrasonication for 30 minutes, centrifuge and wash the obtained pale yellow precipitate, and dry it at 60°C for 12 hours to obtain tungsten oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com