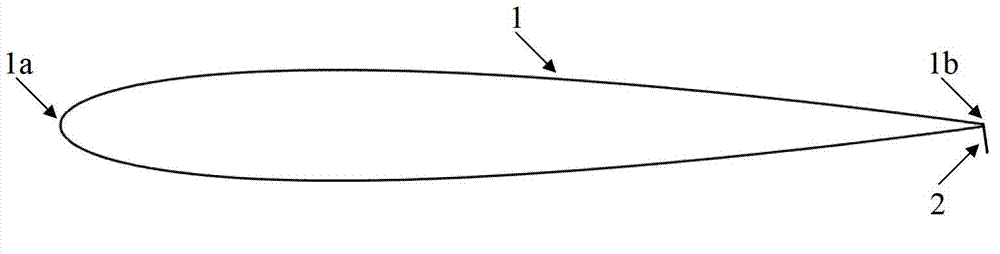

Pneumatic gurney flap based on plasma wall surface jet flow

A technology of plasma and Gurney flaps, applied in the direction of affecting the airflow flowing through the surface of the aircraft, aircraft parts, aircraft control, etc., can solve the problems of reducing the fatigue strength of the wing, increasing the extra weight of the aircraft, and achieving low power consumption , light weight, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

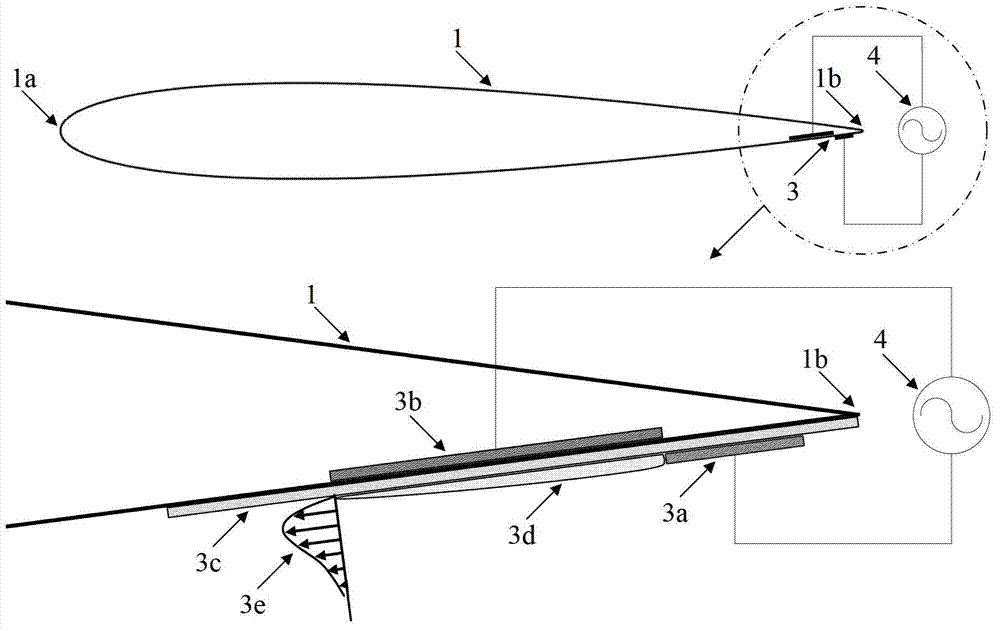

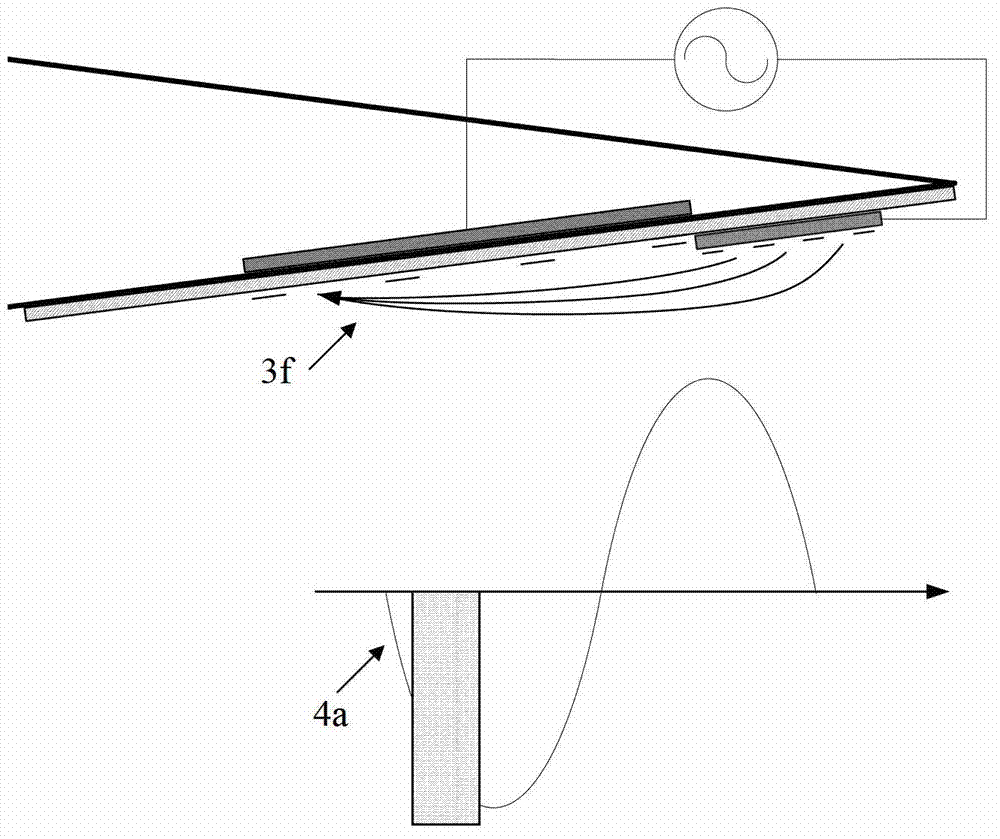

[0032] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0033] The invention proposes an aerodynamic Gurney flap based on plasma wall jet flow, which is realized by a specific layout of plasma exciters on the wing. The plasma actuator is attached to the pressure surface of the wing near the trailing edge. Under the condition of free flow, the power of the plasma actuator is turned on, and the wall jet induced by it is opposite to the direction of the free flow. The two interact. A stable recirculation zone is formed at the trailing edge of the wing to achieve the control effect of the aerodynamic Gurney flap. The wind tunnel force test shows that the aerodynamic Gurney flap based on the plasma wall jet proposed by the present invention can effectively increase the lift of the airfoil, the wing and the aircraft. The aerodynamic Gurney flap of the present invention can also be opened and closed at any time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com