Combined type extracting basket extracting tank

An extraction tank and combined technology, applied in the field of animal and plant extraction equipment structure, to achieve the effect of less dead angle, easy automatic control and high equipment utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

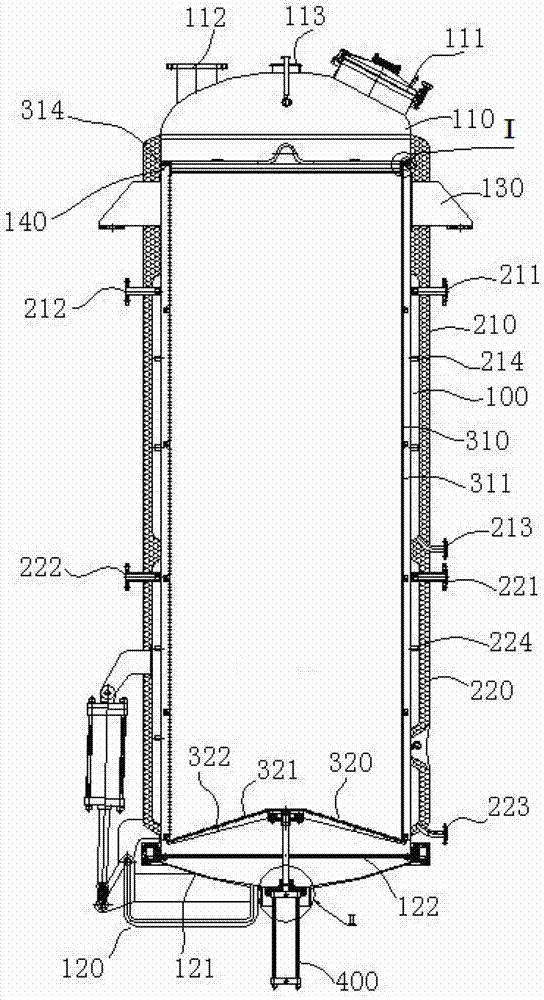

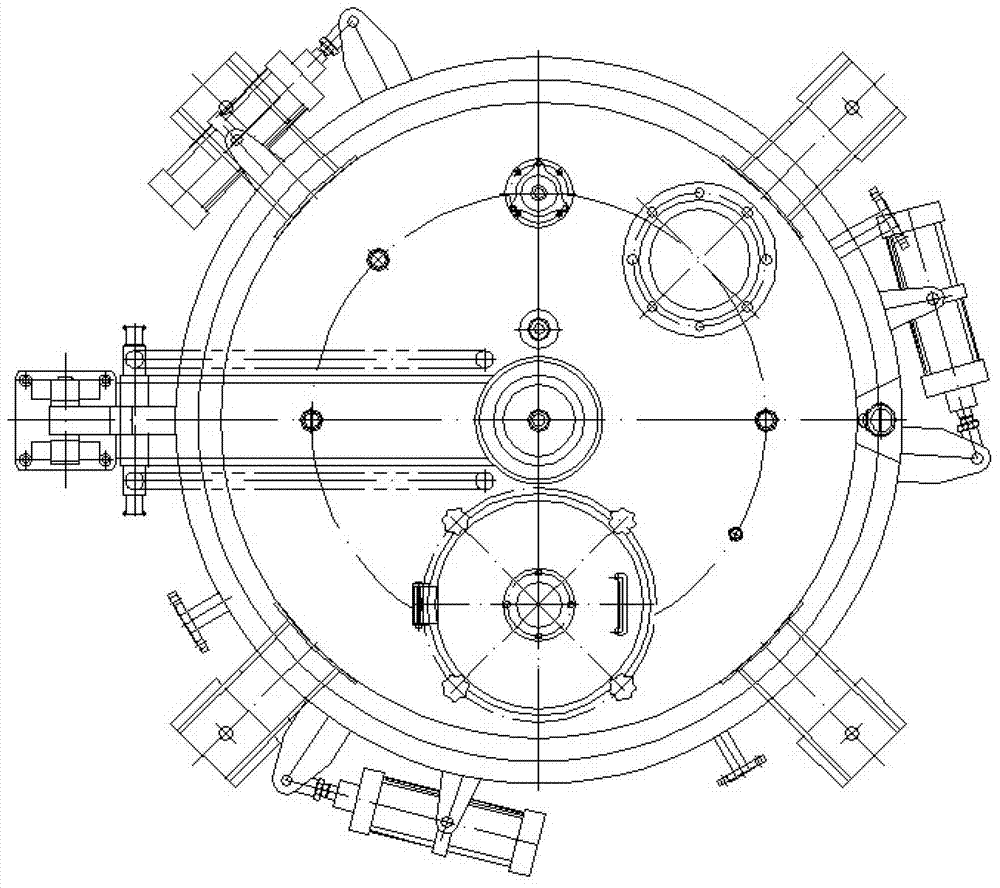

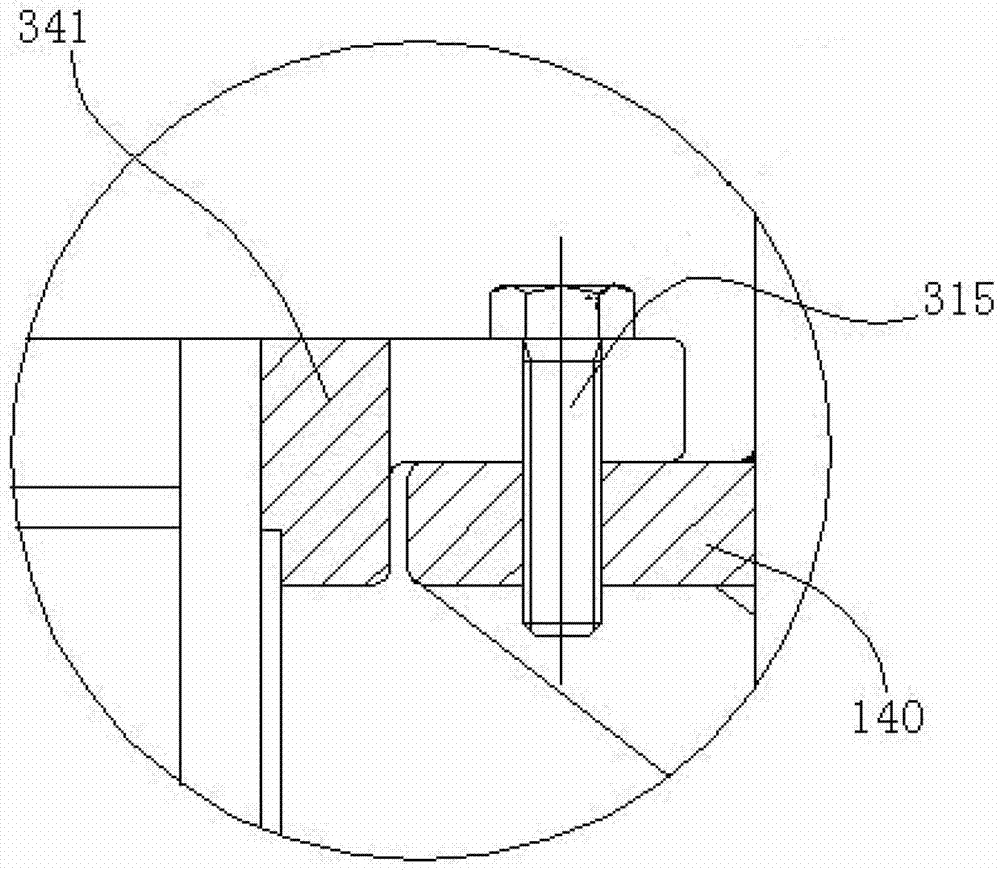

[0017] see figure 1 with figure 2 , the combined blue washing extraction tank shown in the figure includes a tank body 100 and a washing basket. Upper and lower steam jackets 210, 220 are arranged on the outer wall of the tank body 100, and an upper steam inlet pipe 211, an upper steam outlet pipe 212, and an upper condensate discharge pipe 213 are arranged on the upper steam jacket 210, and an upper steam jacket 220 A lower steam inlet pipe 221 , a lower steam outlet pipe 222 and a lower condensed water discharge pipe 223 are arranged on the upper side. Between the inner wall of the upper steam jacket 210 and the outer wall of the tank body 100, a number of upper jacket reinforcement rings 214 are axially spaced apart, and each upper jacket reinforcement ring 214 is provided with a number of steam circulation ports (not shown in the figure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com