Microporous ceramic aerator

A technology of microporous ceramics and aerators, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problems of small aeration area, unsuitable for ponds and factory farming, etc., to increase aeration Gas area, easy assembly and application, and the effect of improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

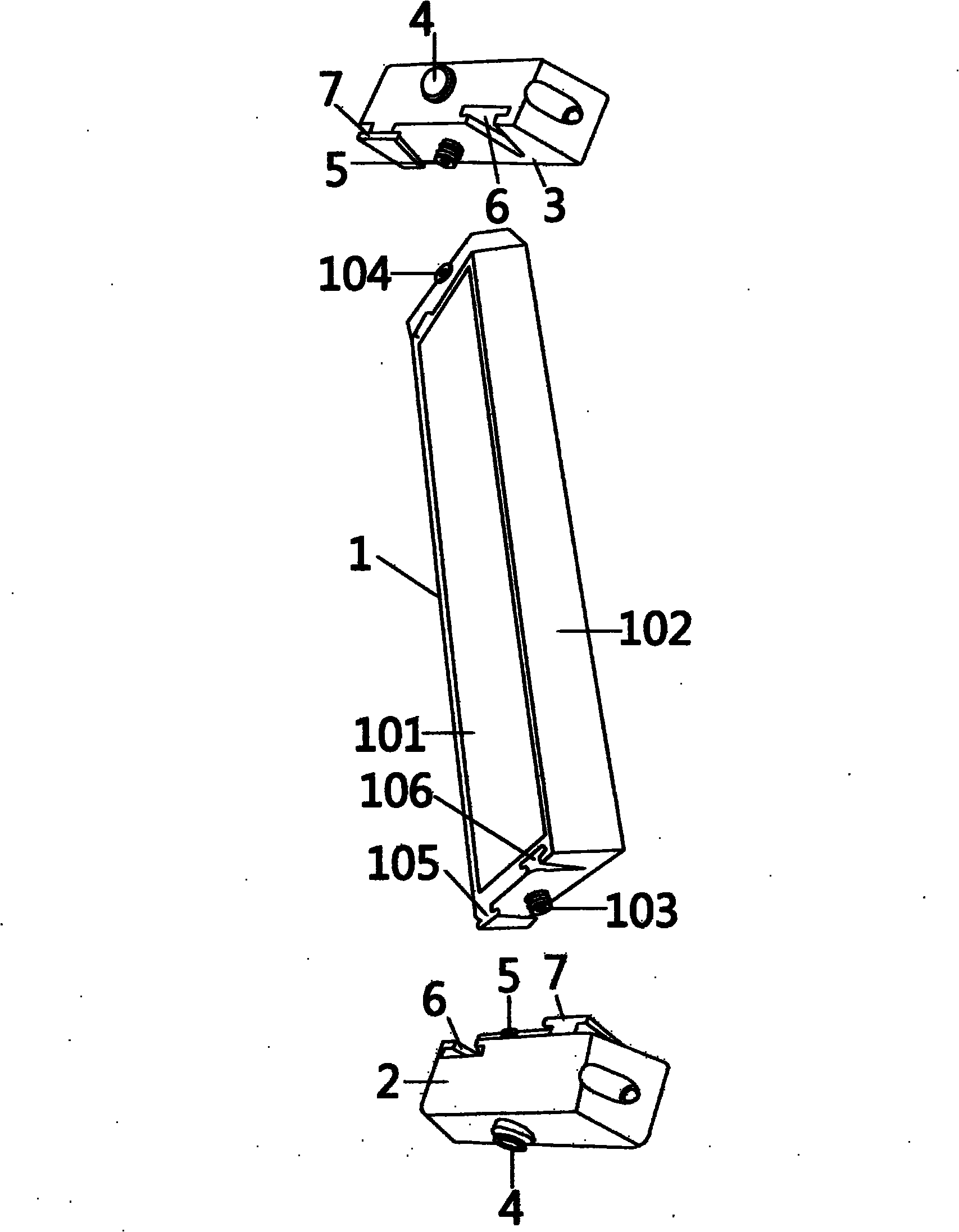

[0024] see figure 1 As shown, a microporous ceramic aerator includes a base part 1, a first end part 2 and a second end part 3; the base part 1 includes a microporous ceramic sheet 101 and a base part cavity cover 102, the The microporous ceramic sheet 101 is bonded to the base cavity cover 102 to form a closed container, one end of the base cavity cover 102 is connected to the first air hole joint 103, and the other end is connected to the second air hole joint 104; the first end The part 2 and the second end part 3 respectively include a closed cavity, one end of the closed cavity is provided with an air filling port 4, and the other end is provided with an air hole interface 5; the air hole interface of the first end part 2 and the second end part 3 5 and respectively screwing and connecting the first air hole joint 103 and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com