Radiating device for high-power relay

A technology of high-power relays and heat sinks, which is applied in the directions of relay ventilation/cooling/heating, etc., which can solve the problems of bulky products and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

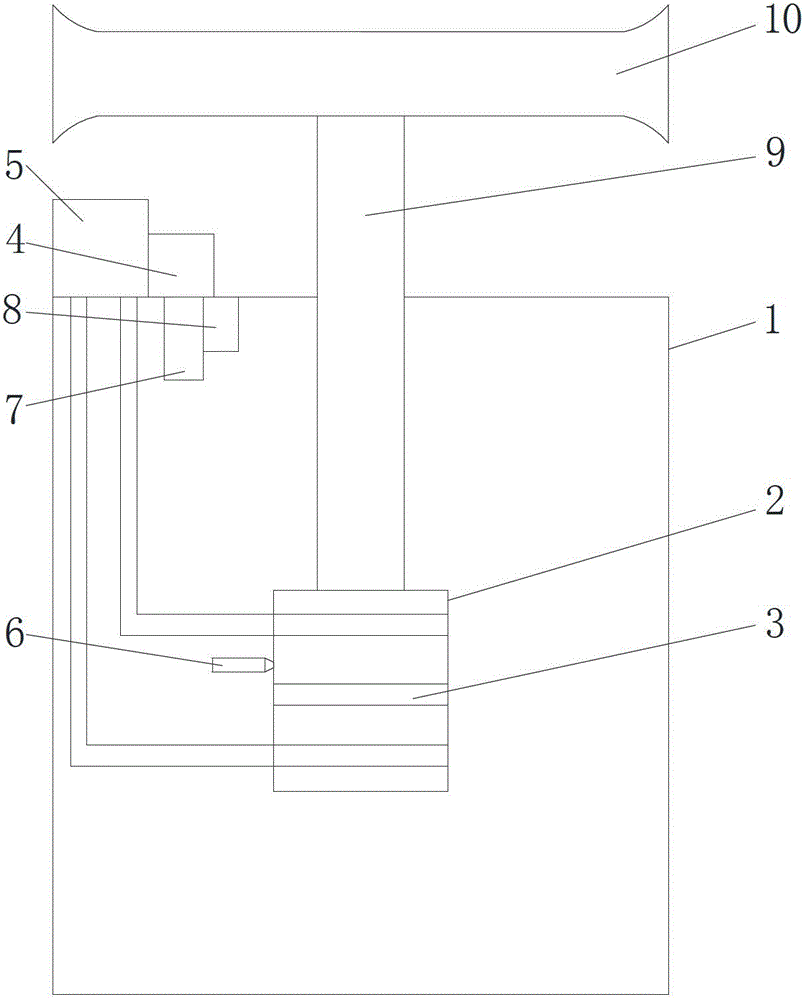

[0010] refer to figure 1 , the heat dissipation device of the high-power relay of the present invention, the box body 1 is provided with a heat conduction mount 2, the back of the heat conduction mount is provided with a disc-shaped pipeline 3, the disc-shaped pipeline 3 is connected to a cooling pump 4, and the cooling pump 4 is connected to a The liquid storage tank 5 that stores the cooling liquid is connected, and a temperature sensor 6 for detecting the temperature on the heat conduction mounting seat is arranged in the box body, and the temperature sensor 6 is connected with a controller 7, and the temperature sensor 6 transmits the detected temperature signal to the controller 7. The controller 7 is a 51 series single-chip microcomputer. The output end of the controller 7 is connected to the driver 8, and the driver 8 is connected to the cooling pump 4. A temperature value is preset in the controller. When the temperature in the box is higher than the preset temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com