Special sampling device for online chromatographic analysis system

A sampling device and chromatographic analysis technology, which is applied in the field of special sampling devices for online chromatographic analysis systems, and can solve the problems of sample component changes, poor analysis result accuracy and stability repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

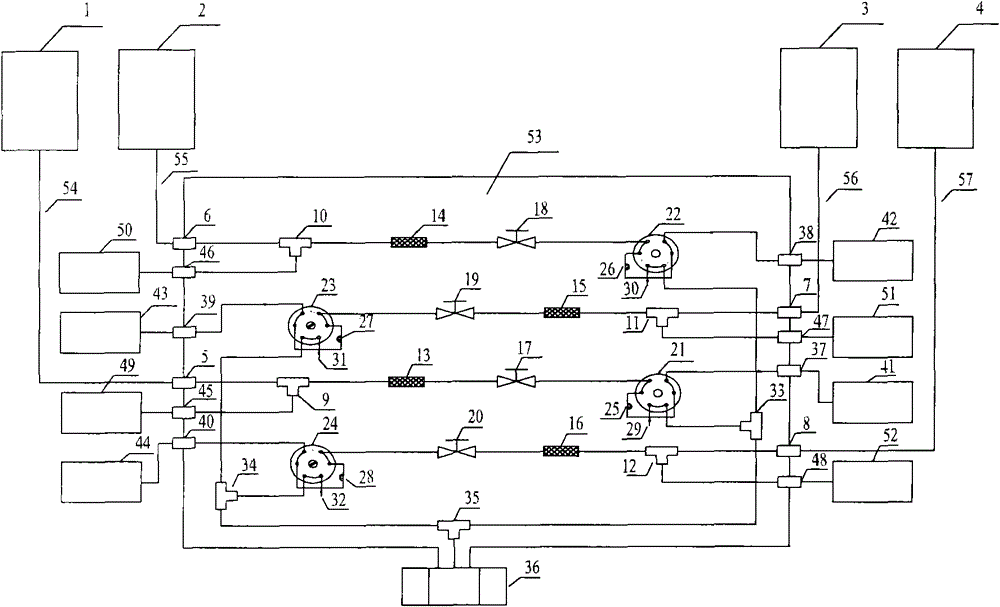

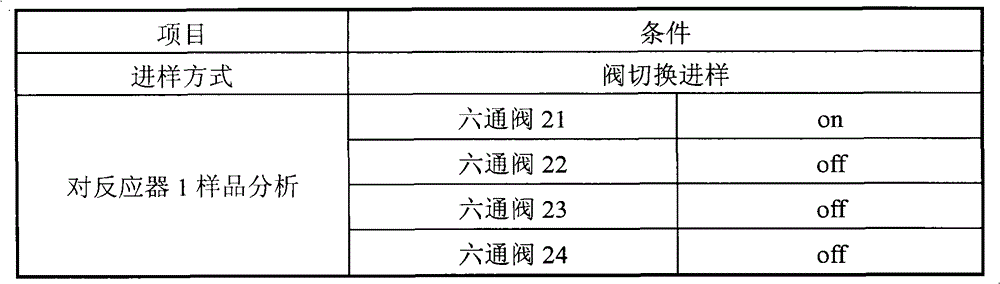

[0019] use figure 1 The shown dedicated sampling device for online chromatographic analysis, under the condition that the reactor is filled with quartz sand instead of the catalyst, analyzes the self-prepared mixed standard sample continuously for 6 times. The typical valve switching conditions are shown in Table 1. Among them, the composition of the standard sample and the results of the 6 parallel analyses are shown in Table 2. The analysis results show that the online chromatographic analysis special sampling device, when performing online chromatographic analysis, the analysis result is consistent with the actual composition of the sample, and the relative standard deviation does not exceed 0.5%, which can fully meet the routine online chromatographic analysis

[0020] Table 1 Valve switching conditions

[0021]

[0022] Table 2 Standard sample analysis results

[0023]

Embodiment 2

[0025] use figure 1 The shown dedicated sampling device for online chromatographic analysis, under the condition that reactor 1 is filled with catalyst and the catalyst is running stably (the operating stage where the conversion rate is basically unchanged), the actual reaction mixture is analyzed in parallel for 5 consecutive times, and Compare the online analysis results with the offline analysis results, see Table 3.

[0026] Table 3 Standard sample analysis results

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com